Cross-linked rubber adhesive, high-bonding-strength shock absorbing and silencing tape applying rubber adhesive and preparation method of rubber adhesive and tape

A cross-linked, adhesive technology, applied in the directions of adhesive additives, adhesives, non-polymer adhesive additives, etc., can solve the problems of insufficient cohesive strength, substandard pendulum impact performance, etc. The effect of good die-cutting performance and excellent aging performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

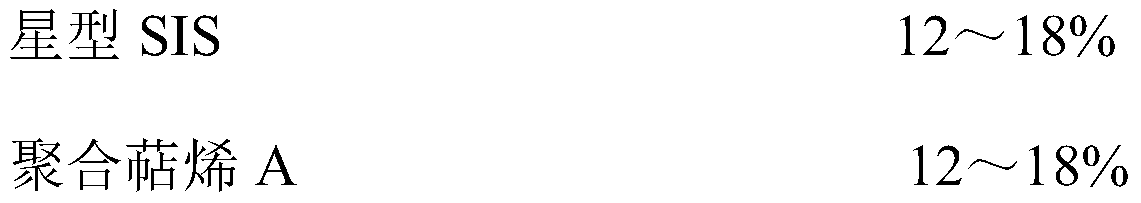

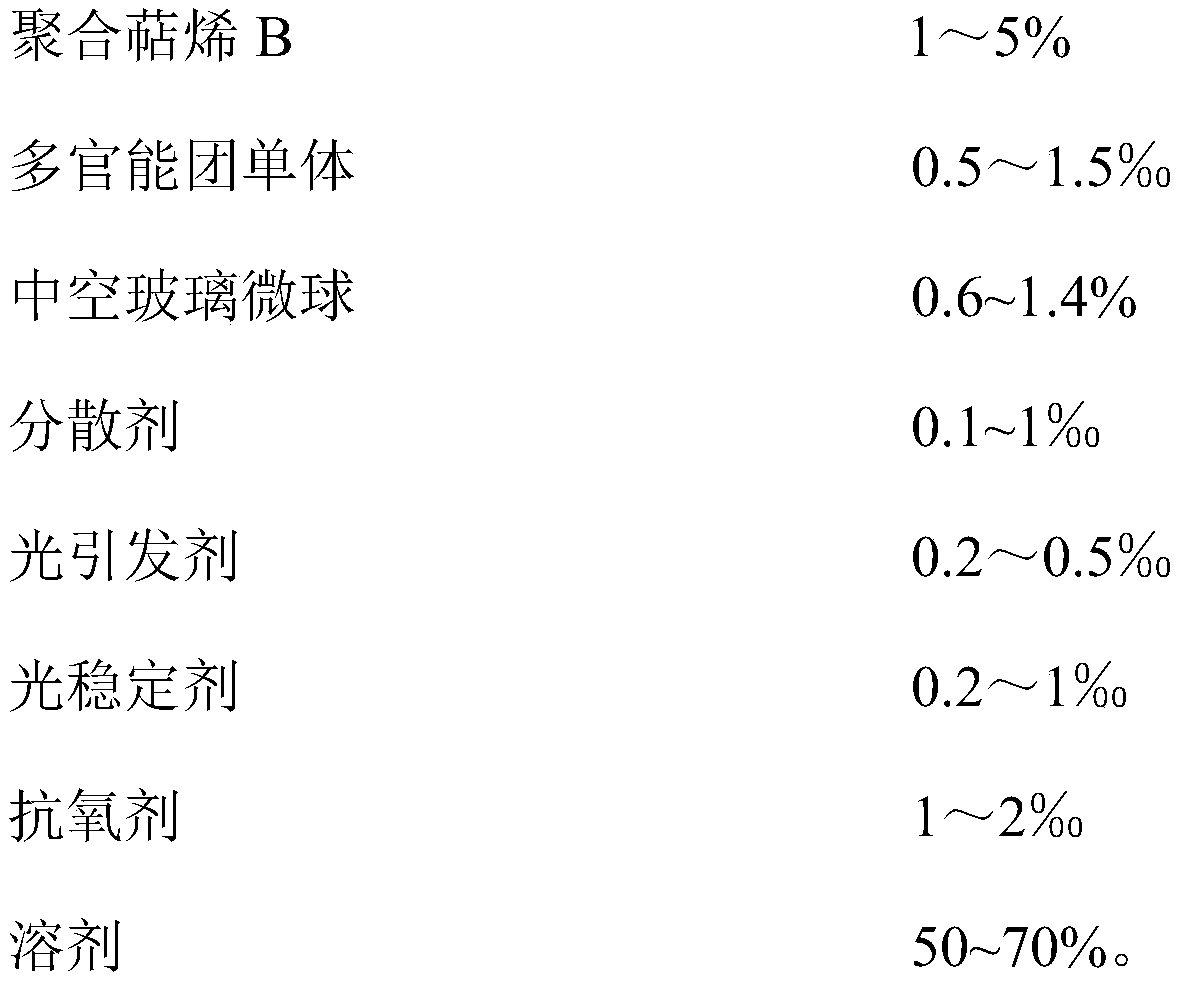

Embodiment 1

[0035]Prepare shock-absorbing and sound-absorbing type high-bond strength adhesive composition: put 434g of 120# solvent oil into a 1000ml light-shielding reaction bottle, then start the stirring device at a speed of 200rpm, and put in 80g of polymerized terpene resin A and polymerized terpene resin in turn while stirring. Vinyl resin B 33g, difunctional monomer HDDA 3.37g, photoinitiator 184 0.13g, light stabilizer Tinuvin144 0.13g, composite antioxidant 1010 and 168 respectively 0.36g and 0.3g, stir for 15min until it dissolves, and then put in Dispersant BYK-111 0.405g and hollow glass microspheres im30K 6.75g, after stirring for 10 minutes, put in 120g of star-shaped SIS, stir for 8 hours to completely dissolve and mix evenly, stop stirring, let it stand for more than 30 minutes to defoam naturally, and the reduced Shock-absorbing type high bond strength adhesive composition;

[0036] Coating process of shock-absorbing and sound-absorbing high-bond strength adhesive: On th...

Embodiment 2

[0038] Prepare shock-absorbing and noise-absorbing type high-bonding strength adhesive composition: put 440g of 120# solvent oil into a 1000ml light-shielding reaction bottle, then start the stirring device, and the rotation speed is 200rpm, and put in 100g of polymerized terpene resin A and polymerized terpene resin in turn while stirring. Vinyl resin B 20g, difunctional monomer HDDA 8g, photoinitiator 184 0.4g, light stabilizer Tinuvin144 0.3g, composite antioxidant 1010 and 168 respectively 0.6g and 0.4g, stir for 15min until it dissolves, then put into the dispersion Agent BYK-111 0.405g and hollow glass microspheres im30K 6.75g, after stirring for 10 minutes, put in 100g of star-shaped SIS, stir for 8 hours to completely dissolve and mix evenly, stop stirring, let it stand for more than 30 minutes to defoam naturally, and you can get shock absorption Sound-absorbing high-bond strength adhesive composition;

[0039] Coating process of shock-absorbing and sound-absorbing hi...

Embodiment 3

[0041] Prepare the shock-absorbing and sound-absorbing type high-bond strength adhesive composition: put 444g of 120# solvent oil into a 1000ml light-shielding reaction bottle, then start the stirring device at a speed of 200rpm, and put in 120g of polymerized terpene resin A and polymerized terpene resin in sequence while stirring. Vinyl resin B 6.7g, difunctional monomer HDDA 10g, photoinitiator 184 0.7g, light stabilizer UV-328 0.7g, composite antioxidant 1010 and 168 respectively 0.96g and 0.4g, stir for 15min until it dissolves, Then add 0.405g of dispersant BYK-111 and 6.75g of hollow glass microspheres K15, stir for 10 minutes, and finally put in 80g of star-shaped SIS, stir for 8 hours to completely dissolve and mix evenly, stop stirring, and let it stand for more than 30 minutes to defoam naturally. Obtain a shock-absorbing and sound-absorbing type high-bond strength adhesive composition;

[0042] Coating process of shock-absorbing and sound-absorbing high-bond streng...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com