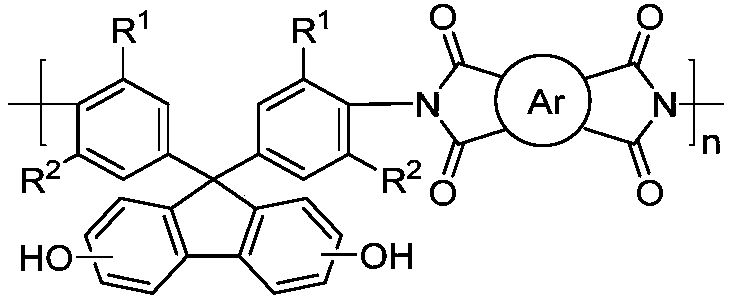

Fluorine ion color development sensing polyimide film and preparation method and application thereof

A technology for sensing polyimide and polyimide films, which is used in the fields of ion detection and material science to achieve the effects of convenient fabrication, excellent thermal stability, and enhanced charge transfer effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

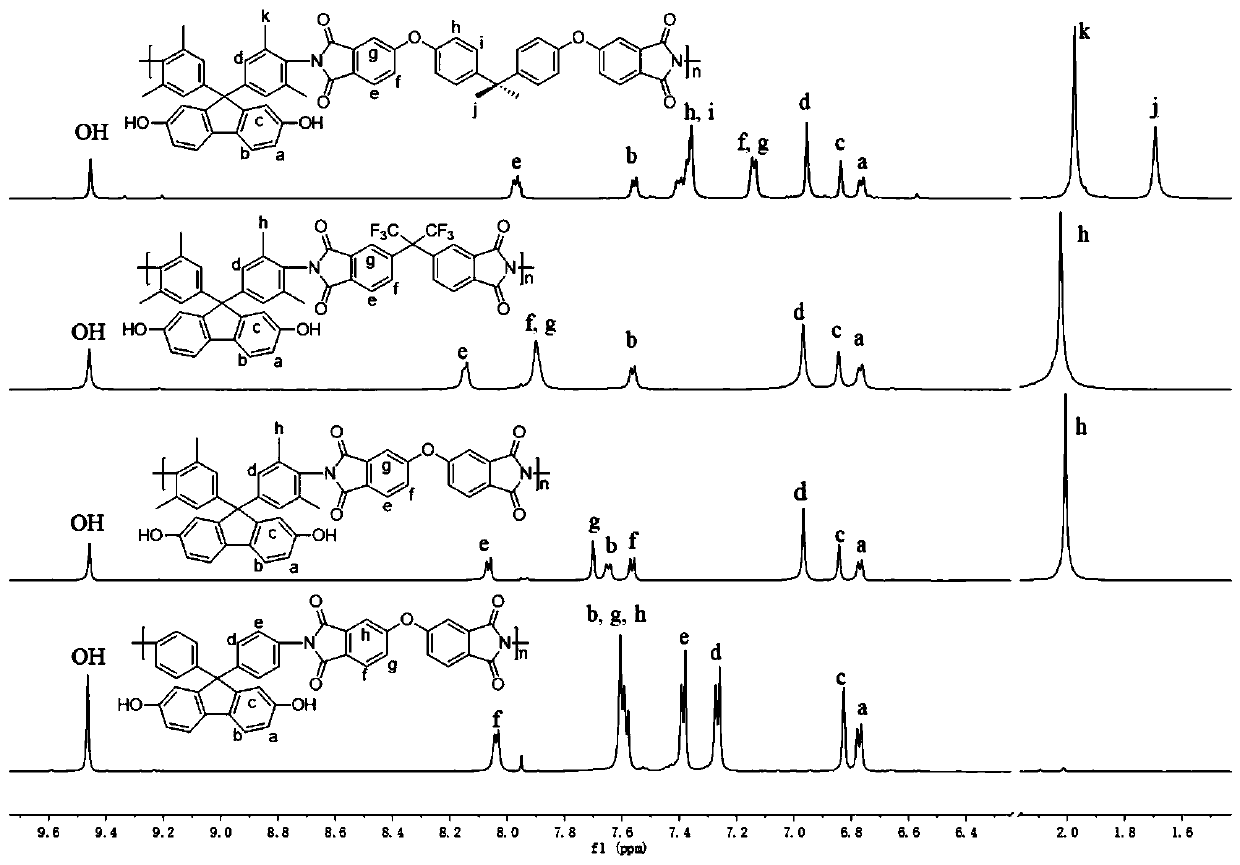

[0039]Add 1.241g of 4,4'-oxydiphthalic anhydride (ODPA) and 1.522g of 2,7-dihydroxy-9,9-bis(4-aminophenyl)fluorene (AHF) into a 100mL one-necked flask , add 25 ml of m-cresol as a solvent, 8 drops of isoquinoline as a catalyst, stir and mix evenly, vacuumize at room temperature-argon circulation twice, and then under the protection of argon, at 85 ° C and 200 ° C respectively Each reaction was 12 hours; the reaction was completed, cooled to room temperature to obtain a viscous polyimide solution; it was added dropwise to 400mL ethanol to produce a fibrous precipitate, after the addition was completed, stand and filter; the precipitate was placed at 100°C Dry under vacuum for 10 hours to obtain fibrous polyimide; take partly dried fibrous polyimide and dissolve it in N,N-dimethylacetamide, control the solid content to 10%, fully stir and dissolve, and spread evenly On a clean silica glass plate, vacuum several times until there are no bubbles, dry in a vacuum oven at 70°C for 1...

Embodiment 2

[0043] 1.241g 4,4'-oxydiphthalic anhydride (ODPA) was mixed with 1.572g 2,7-dihydroxy-9,9-bis(3,5-dimethyl-4-aminophenyl)fluorene ( DMAHF) into a 100mL single-necked flask, add 30ml of N,N-dimethylformamide as a solvent, 6ml of acetic anhydride and 4ml of pyridine as a catalyst, magnetically stir and mix evenly, vacuumize at room temperature and circulate twice with argon , and then under the protection of argon, reacted at 25°C for 6 hours, then raised the temperature to 150°C and continued to react for 18 hours; ended the reaction, cooled to room temperature, and obtained a viscous polyimide solution; added it dropwise to 400mL ethanol During the process, a fibrous precipitate was produced, and after the dropwise addition was completed, it was left to stand and filtered; the precipitate was vacuum-dried at 105°C for 8 hours to obtain a fibrous polyimide; the partially dried fibrous polyimide was dissolved in N,N- In dimethylformamide, the solid content is controlled to be 10...

Embodiment 3

[0047] Add 1.746g of 4,4'-(hexafluoroisopropylene) diphthalic anhydride (6FDA) and 1.921g of 2,7-dihydroxy-9,9-bis(4-aminophenyl)fluorene (DMAHF) to a 100mL single port In the flask, add 30 ml of m-cresol as a solvent, 10 drops of isoquinoline as a catalyst, magnetically stir and mix evenly, vacuumize at room temperature-argon circulation twice, and then react at 80°C under the protection of argon 6 hours, then raise the temperature to 220°C and react for 6 hours; end the reaction, cool to room temperature to obtain a viscous polyimide solution; add it dropwise to 500mL ethanol to produce a fibrous precipitate, after the addition is completed, let it stand Filtration; vacuum drying the precipitate at 95°C for 12 hours to obtain a fibrous polyimide; dissolving the partially dried fibrous polyimide in N,N-dimethylacetamide to control the solid content to 10%, After fully stirring and dissolving, spread it evenly on a clean silica glass plate, vacuumize it several times until the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com