A method for reducing air bubbles generated by lamination of waterproof protective film and segment code liquid crystal device

A protective film and air bubble technology, which is applied in the direction of instruments, optics, nonlinear optics, etc., can solve the problem of a large number of air bubbles in the waterproof protective film, and achieve the effect of improving product quality, reducing air bubbles, and meeting waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

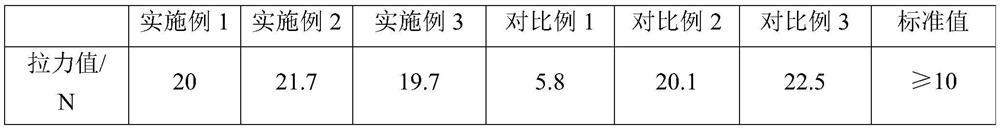

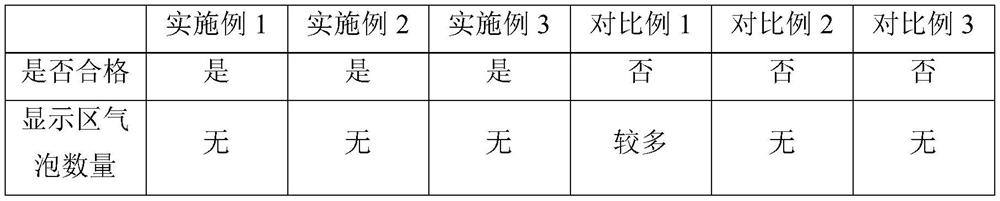

Examples

Embodiment 1

[0029] A method for reducing air bubbles in the bonding of a waterproof protective film, comprising the following steps:

[0030] Step S1: tear off the release film on the surface of the electronic paper of the product, and perform plasma cleaning. The plasma cleaning includes step S11 carbon tetrafluoride and oxygen combined cleaning and step S12 oxygen cleaning;

[0031] In step S11, the parameters in the combined cleaning of carbon tetrafluoride and oxygen are set to 200ppm carbon tetrafluoride, 150ppm oxygen, 50°C temperature, 35MPa vacuum, 5min time, and 4000W power;

[0032] The parameters in step S12 oxygen cleaning are set as oxygen amount 150ppm, temperature 50°C, vacuum degree 35MPa, time 3-8min, power 4000W;

[0033] Conduct electrical testing after plasma cleaning, and observe whether the product is damaged;

[0034] The product after plasma cleaning needs to be tested for water drop angle within 24 hours. If the contact angle of the test is less than 25°, it is q...

Embodiment 2

[0040] A method for reducing air bubbles in the bonding of a waterproof protective film, comprising the following steps:

[0041] Step S1: tear off the release film on the surface of the electronic paper of the product, and perform plasma cleaning. The plasma cleaning includes step S11 carbon tetrafluoride and oxygen combined cleaning and step S12 oxygen cleaning;

[0042] In step S11, the parameters in the combined cleaning of carbon tetrafluoride and oxygen are set as carbon tetrafluoride 250ppm, oxygen 200ppm, temperature 52°C, vacuum 40MPa, time 7min, and power 3900W;

[0043] The parameters in step S12 oxygen cleaning are set as 200ppm oxygen, 52°C temperature, 40MPa vacuum, 7min time, and 3900W power;

[0044] Conduct electrical testing after plasma cleaning, and observe whether the product is damaged;

[0045] The product after plasma cleaning needs to be tested for water drop angle within 24 hours. If the contact angle of the test is less than 25°, it is qualified and...

Embodiment 3

[0051] A method for reducing air bubbles in the bonding of a waterproof protective film, comprising the following steps:

[0052] Step S1: tear off the release film on the surface of the electronic paper of the product, and perform plasma cleaning. The plasma cleaning includes step S11 carbon tetrafluoride and oxygen combined cleaning and step S12 oxygen cleaning;

[0053] In step S11, the parameters in the combined cleaning of carbon tetrafluoride and oxygen are set as carbon tetrafluoride 250ppm, oxygen 200ppm, temperature 47°C, vacuum 30MPa, time 4min, and power 3900W;

[0054] The parameters in step S12 oxygen cleaning are set as oxygen amount 200ppm, temperature 47°C, vacuum degree 30MPa, time 4min, power 4100W;

[0055] Conduct electrical testing after plasma cleaning, and observe whether the product is damaged;

[0056] The product after plasma cleaning needs to be tested for water drop angle within 24 hours. If the contact angle of the test is less than 25°, it is quali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com