Rubber tyre curing method

A curing method and technology for rubber tires, applied in the field of curing rubber tires, can solve problems such as condensation of water vapor, reduce temperature difference, improve quality, and solve insufficient vulcanization or long time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0031] The invention provides a method for curing rubber tires, which includes the step of vulcanizing with a vulcanizing device, and vulcanizing and molding the green tire base through the vulcanizing step.

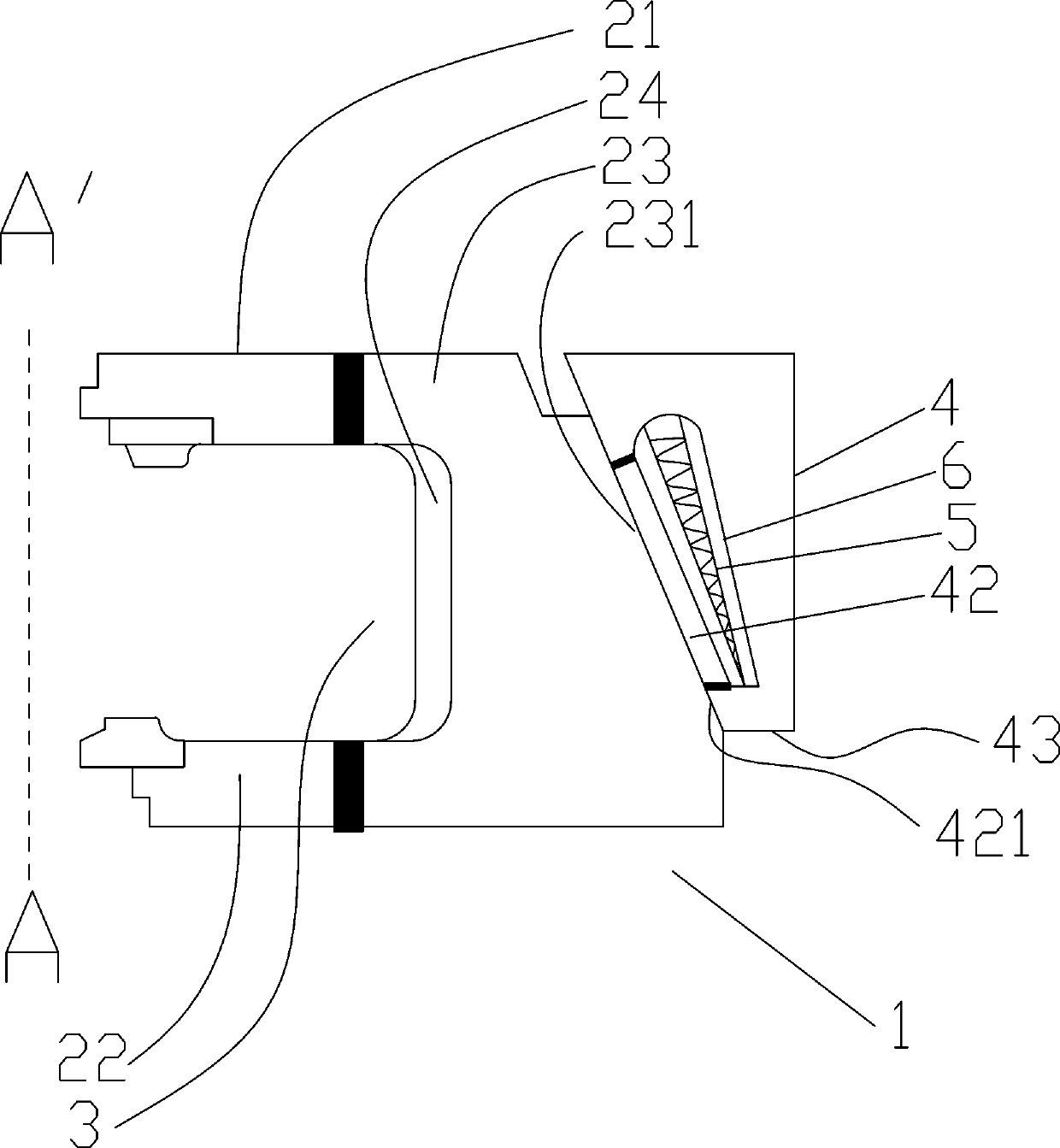

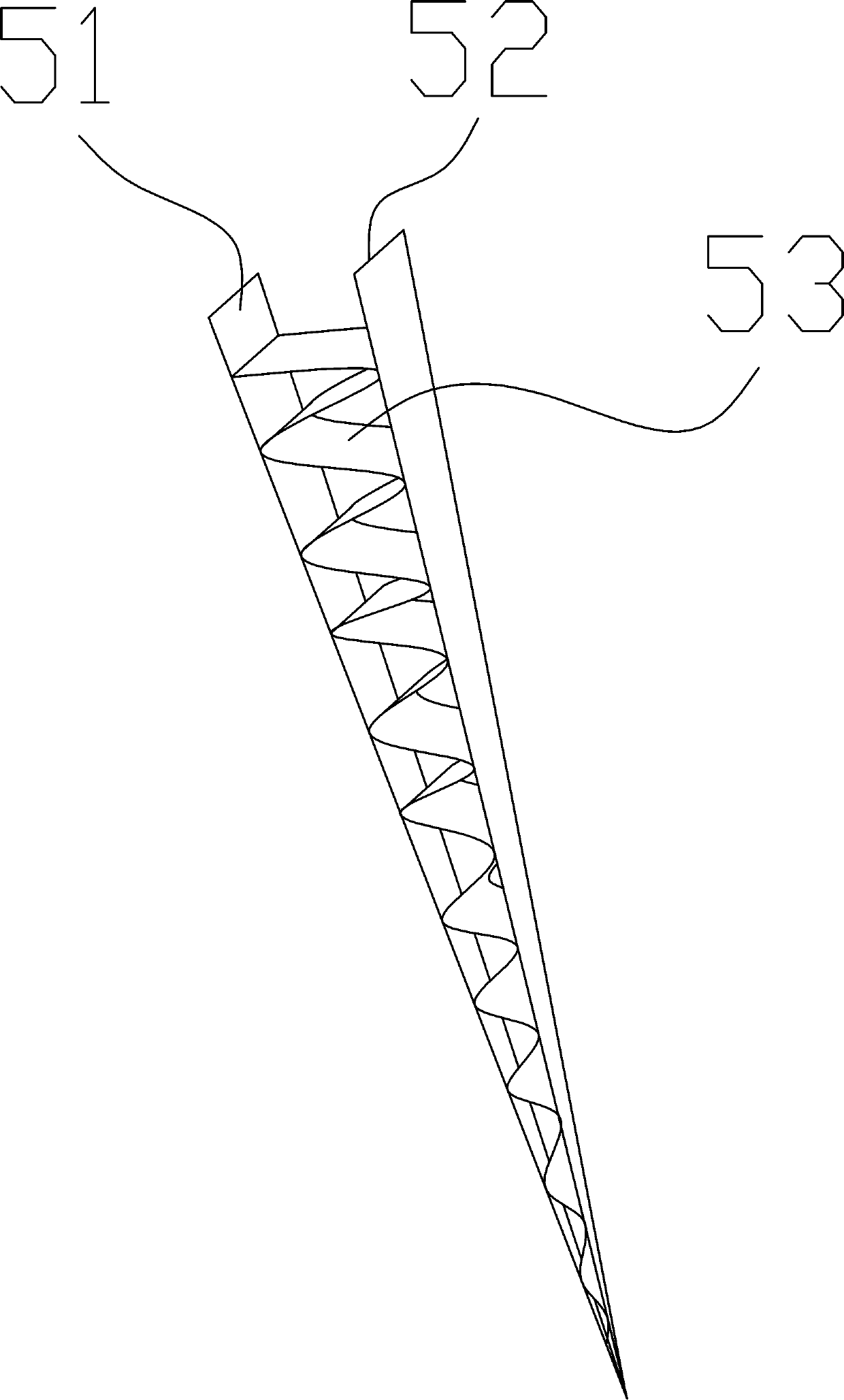

[0032] The structure of the specific vulcanization device 1 is as follows: figure 1 As shown, the vulcanization device 1 is rotationally symmetrical about the axis A-A'. It includes an upper mold 21 located above, a lower mold 22 located below, and an outer mold 23 located on the outside. The outer mold 23 has a frustum-shaped outer surface 231; the inner side of the outer mold 23 is also stacked with The inner mold 24, the upper mold 21, the lower mold 22 and the inner mold 24 form a closed inner cavity 3; the vulcanization device also includes a snap ring 4, which can move in the axial direction and is used for engaging The outer surface 231 of the outer mold 23; the snap ring 4 includes an annular inner pedestal 42 and an outer snap ring 43 with a concave cavity insi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com