Indoor-volatile-organic-contaminant removing device based on thermal desorption and cooling extraction

A volatile organic compound extraction technology, which is applied in the field of indoor environmental purification, can solve the problems of short aldehyde removal time, no longer having adsorption capacity, damage, etc., and achieves the effects of simple operation, obvious formaldehyde removal effect and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with specific embodiments.

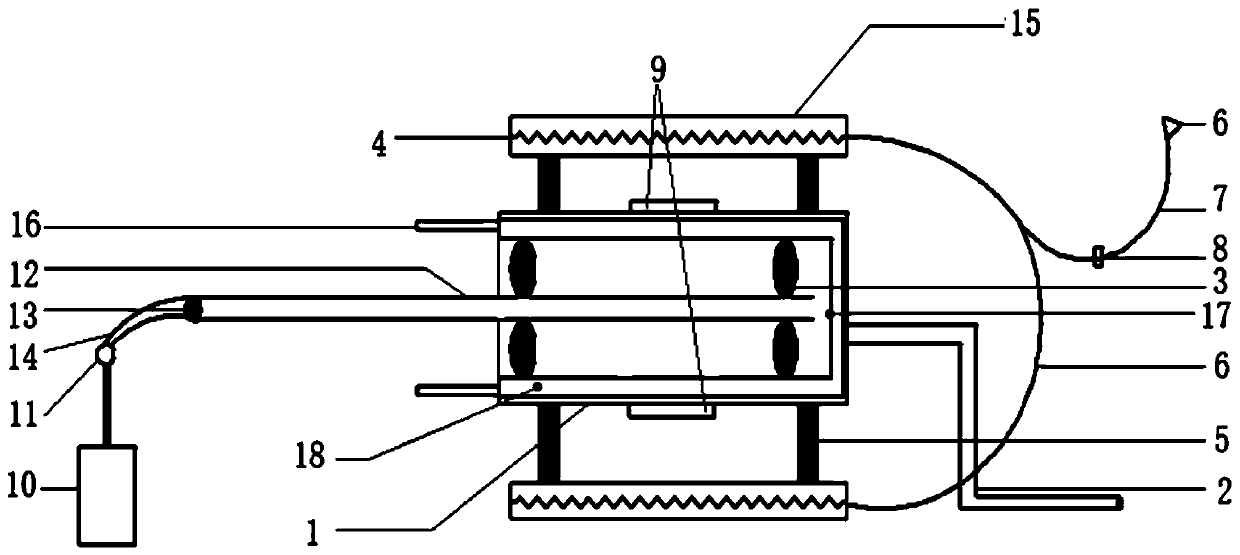

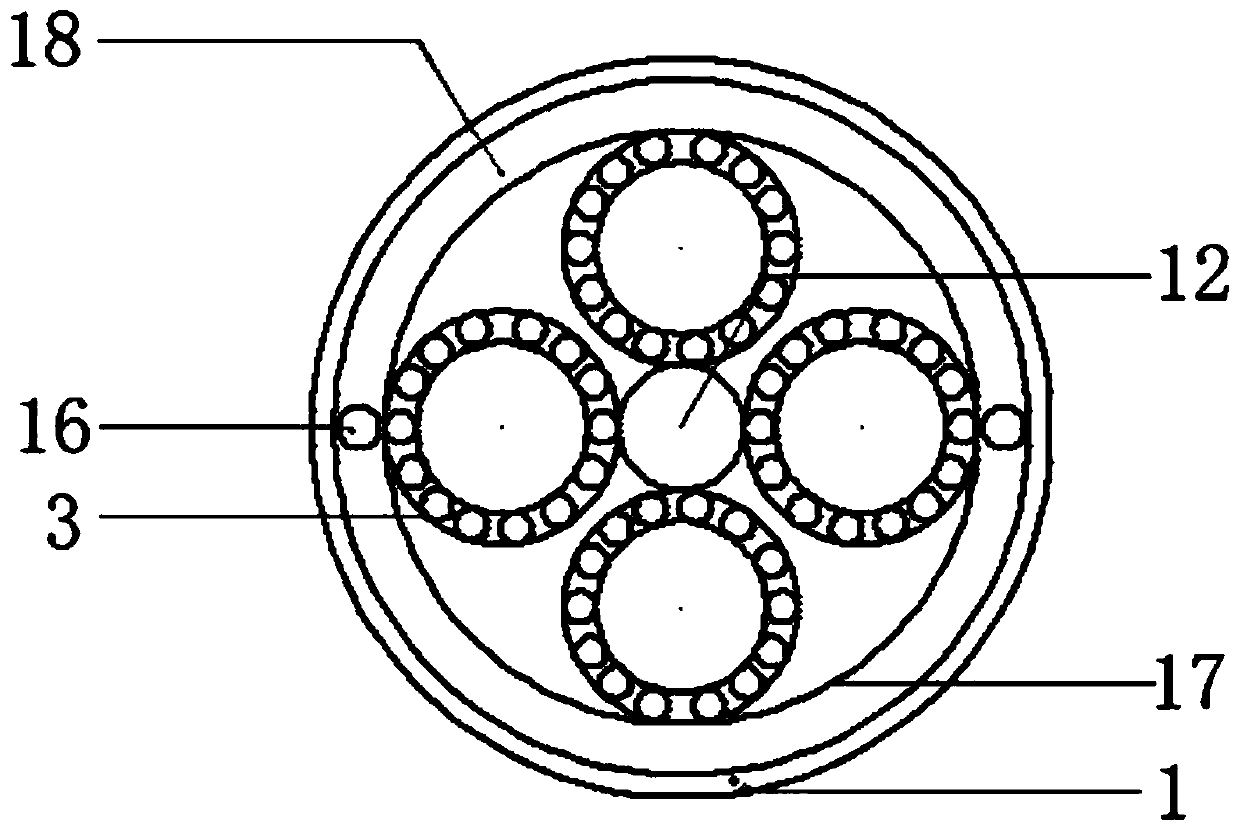

[0043] Such as figure 1 , figure 2 As shown, an indoor volatile organic compound removal device based on thermal desorption and cold extraction includes a roller support unit, a thermal desorption unit, a cooling extraction unit, and a nano-adsorption degradation unit;

[0044] The roller support unit is used to load the solid phase extraction coating, control the rotation of the roller, and enhance the adsorption effect;

[0045] The thermal desorption unit includes a heating rod 4, which provides a heat source for heating the sample and promotes the extraction of volatile organic pollutants;

[0046] The cooling extraction unit includes a liquid carbon dioxide cylinder 10 for providing liquid carbon dioxide to absorb heat to produce a low-temperature environment, and forming a temperature gradient with the heat source provided by the heating rod 4, which is beneficial to the ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com