Method for preventing adhesion and clogging of mineral raw material

A technology of mineral raw materials and raw materials, applied in chemical instruments and methods, dry solid materials, transportation and packaging, etc., can solve problems such as pipe blockage, coal transportation efficiency reduction, thermal power plant power generation efficiency reduction, etc., to achieve effective transportation and prevent adhesion and clogging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

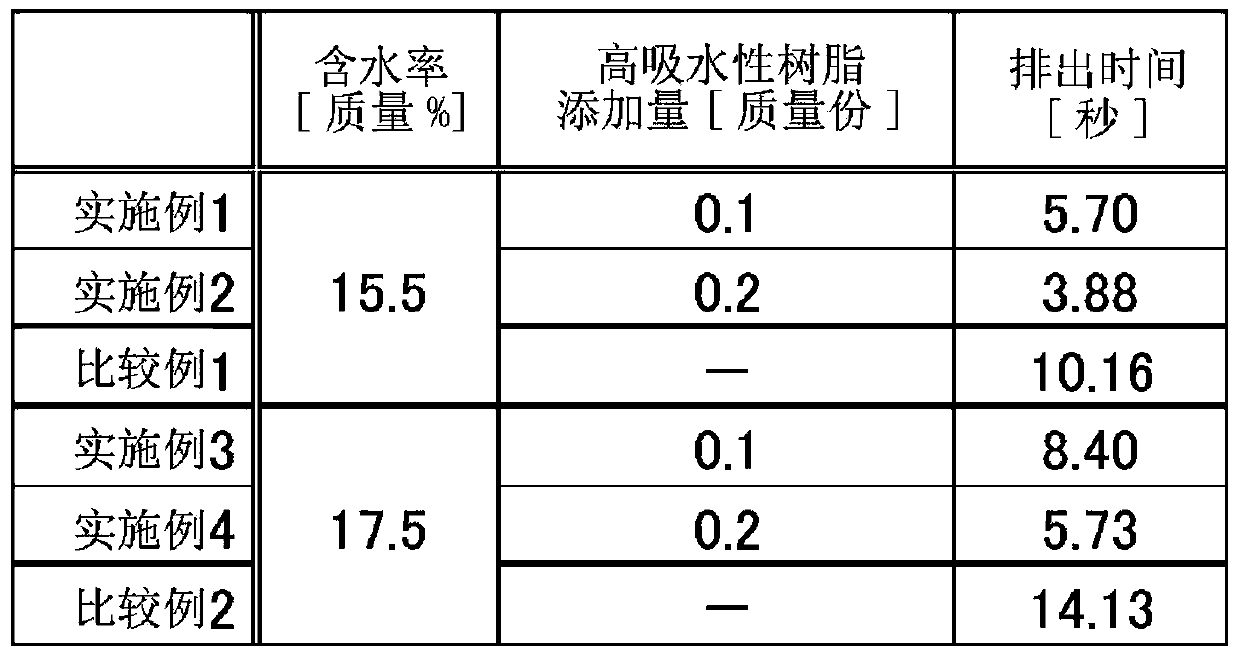

[0062] Add 0.1% by mass of "KURILINE S-200" (manufactured by Kurita Kogyo Co., Ltd.; sodium polyacrylate) as a superabsorbent resin to 1,000 g of wet coal (moisture content: 15.5% by mass, particle size: 2 mm or less), and stir evenly Mixing, raw material mixture samples were prepared.

[0063] Used on the upper part of the electric sieve ("ANF-30", manufactured by Nippon Science and Technology Co., Ltd.) instead of the sieve, a simulated hopper (inlet: 200mm×200mm, discharge port: 30mm×50mm) is installed in the shape of an inverted quadrangular pyramid; made of steel ) vibration test device, the adhesion evaluation test of the raw material mixture sample was carried out.

[0064] Adhesion evaluation was carried out by putting the prepared raw material mixture sample into the dummy hopper of the vibration tester, and measuring the discharge time from the time of putting it in until it fell onto the lower tray of the vibration tester.

[0065] In addition, regarding the moistu...

Embodiment 2~4

[0068] The discharge time of the raw material mixture sample was measured in the same manner as in Example 1 except that the water content of coal and the addition amount of the superabsorbent resin were changed as shown in Table 1 below.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com