Prefabricated distribution transform rack

A distribution transformer platform, pre-installed technology, applied in the substation installed on the column, the configuration/arrangement of fuses, the board/panel/desk of the substation/switchgear, etc., can solve the problem that there is no guarantee of quality, quality factors Different people, wide coverage and other issues, to achieve quality assurance, the same coefficient of thermal expansion and contraction, and solve the effect of poor weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

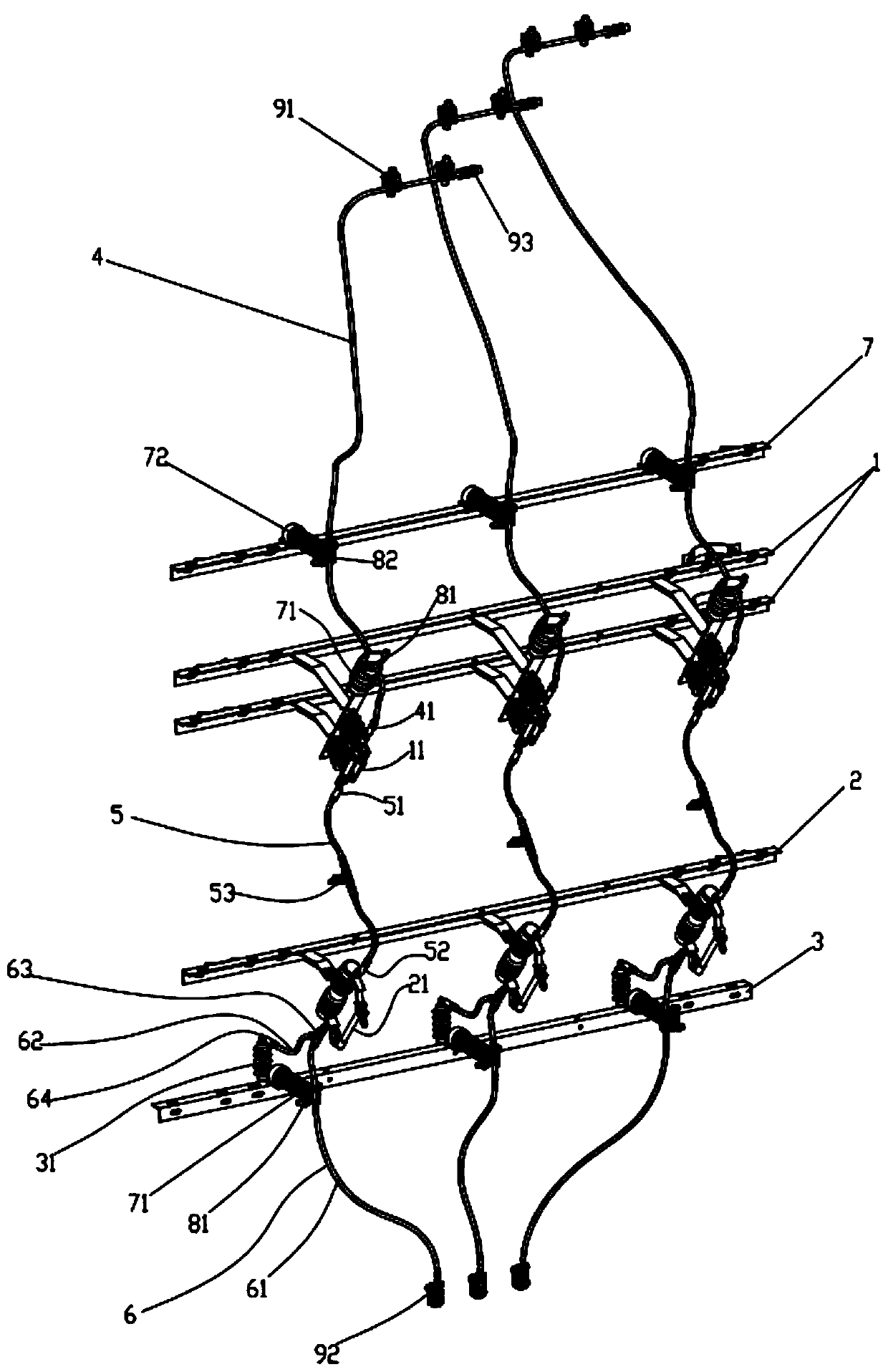

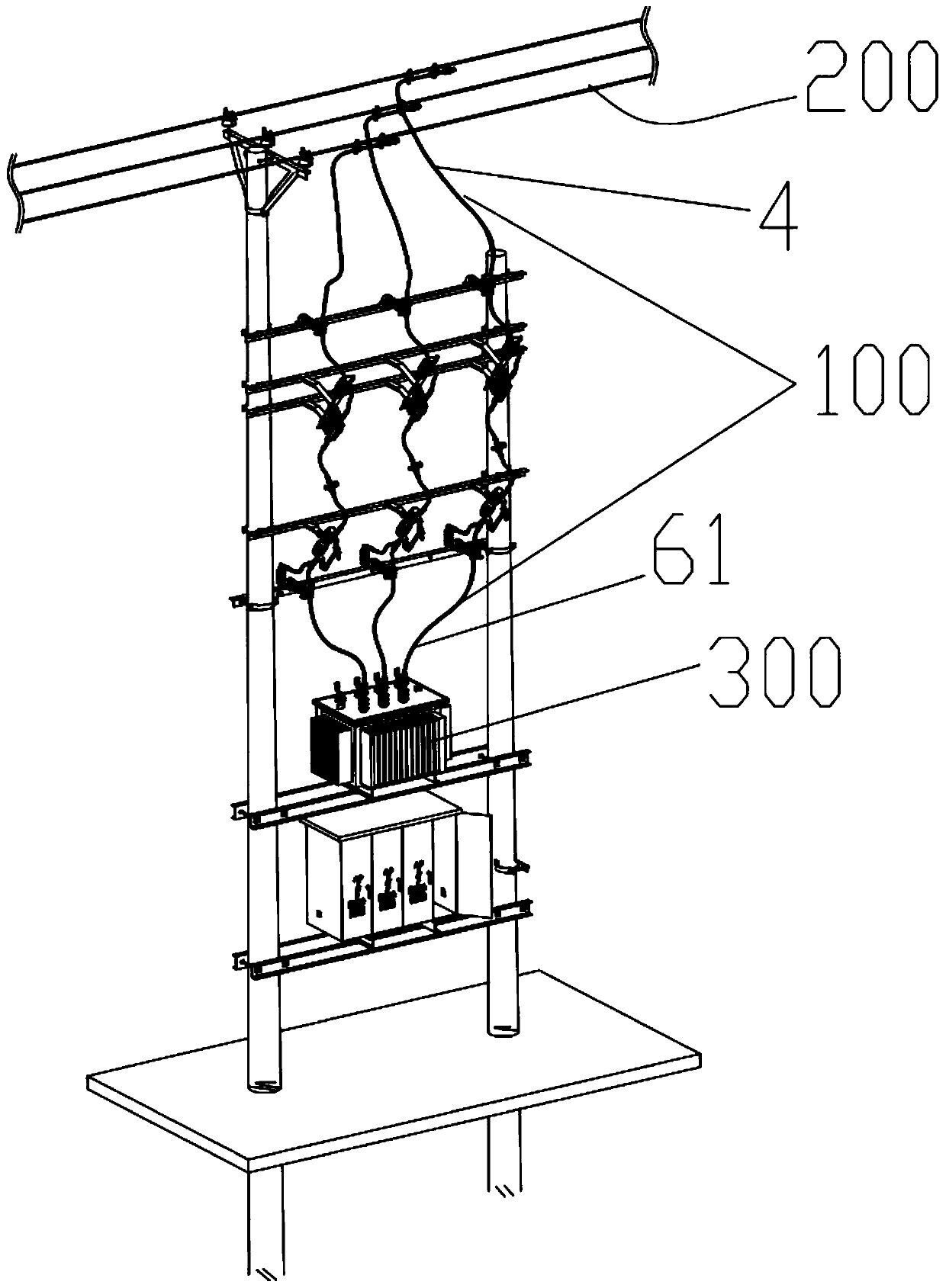

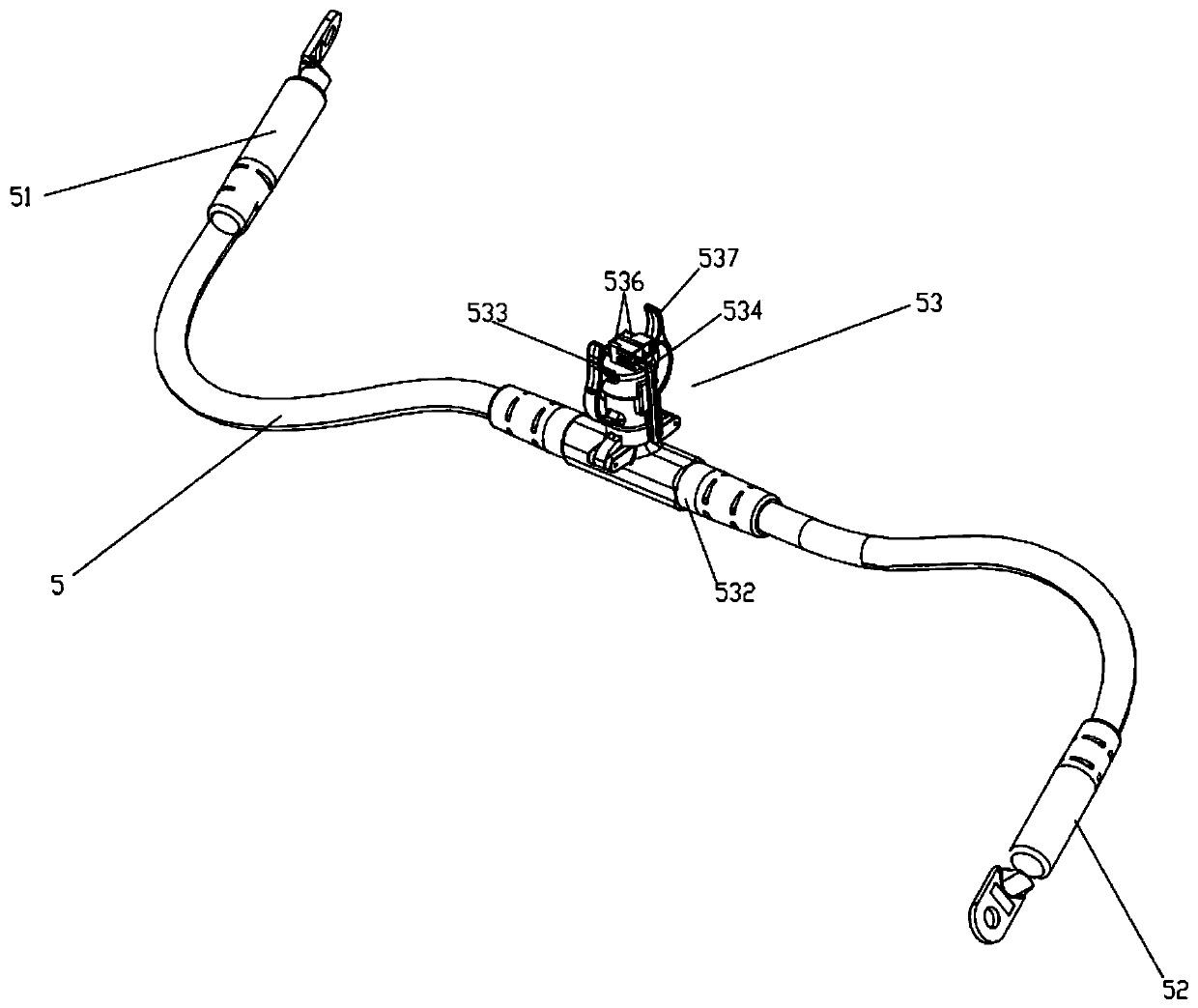

[0024] like Figure 1-2As shown, a prefabricated distribution transformer bench 100 includes a disconnector horizontal frame 1, a fuse horizontal frame 2, an arrester horizontal frame 3, three first-section lead wires 4, three second-section lead wires 5 and Three lead wires 6 of the third section, three isolating switches 11 are fixedly installed on the isolation switch horizontal frame 1, three fuses 21 are fixedly installed on the fuse horizontal frame 2, and three lightning arresters 31 are arranged on the lightning arrester horizontal frame 3, each The first section lead wire 4, the second se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com