Device for testing insulation characteristics of low temperature insulation material based on conductive cooling

A technology of conduction cooling and low-temperature insulation, which is applied in the direction of test ship construction, test dielectric strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

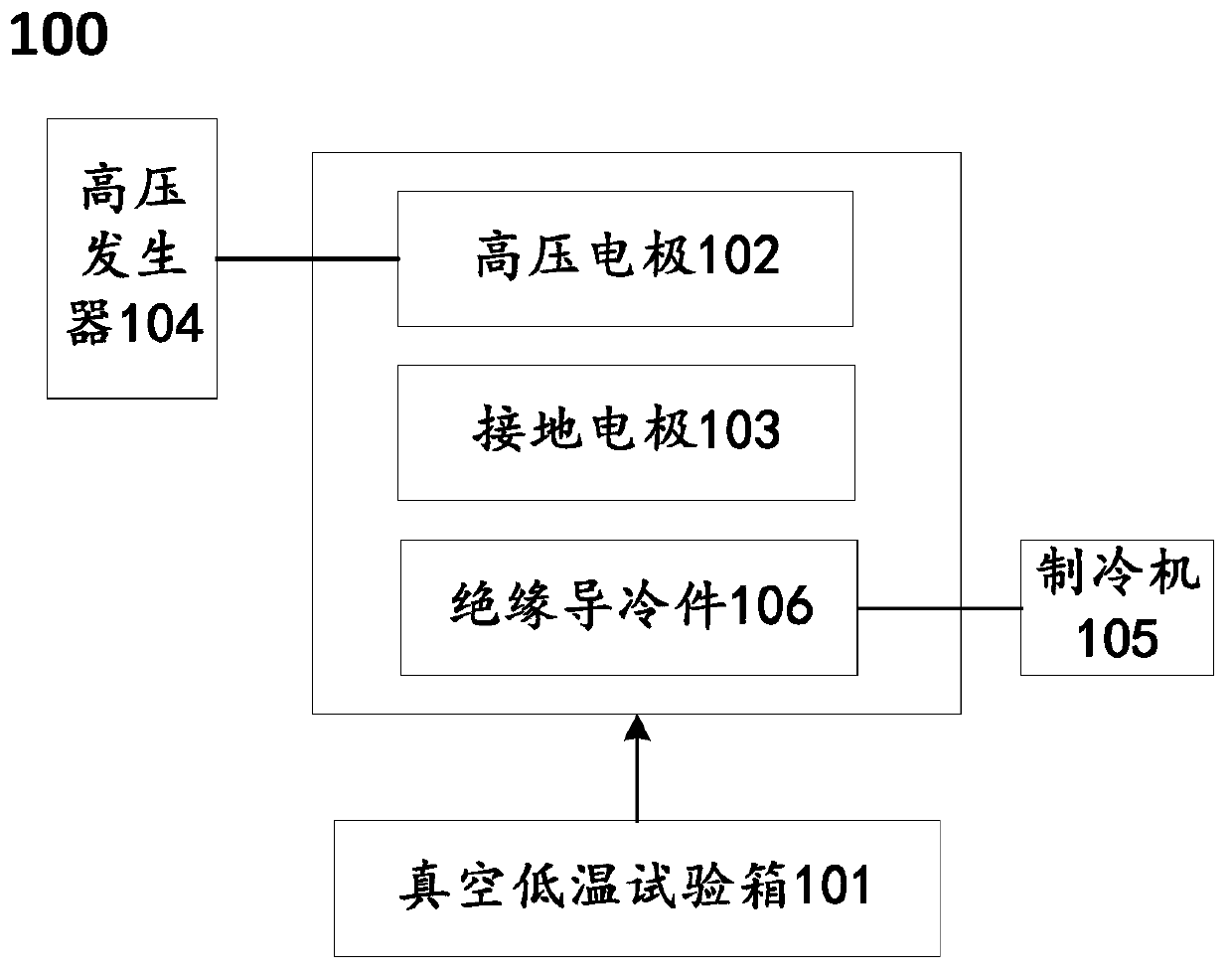

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

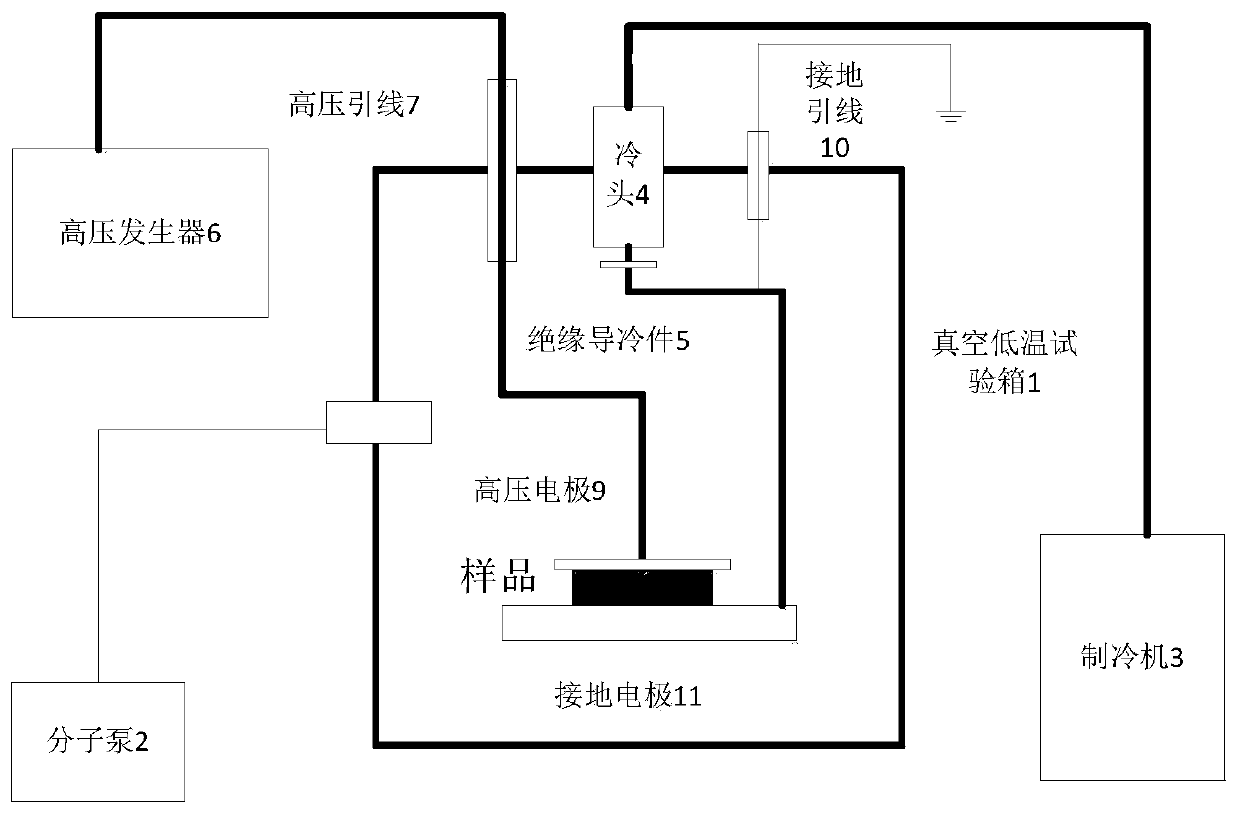

[0045] figure 2 It is a structural schematic diagram of a device for testing the insulation properties of insulating materials using disk-shaped electrodes according to an embodiment of the present invention. Such as figure 2 As shown, the device for testing the insulation properties of insulating materials using disk-structured electrodes includes: vacuum low temperature test chamber 1, molecular pump 2, refrigerator 3, cold head 4, insulating cooling guide 5, high voltage generator 6, high voltage lead wire 7 , High-voltage bushing 8, high-voltage electrode 9, grounding lead 10 and grounding electrode 11. Among them, the high-voltage electrode 9, the ground electrode 11 and the insulating cooling member 5 are located inside the vacuum low-temperature test chamber; the vacuum low-temperature test chamber 1 is evacuated by the molecular pump 2; the cold generated by the refrigerator 3 is passed through the cold head 4 to the ground electrode 11 for cooling; the high voltag...

Embodiment 2

[0049] In the embodiment of the present invention, only the structure of the high-voltage electrode and the ground electrode is different from that in Embodiment 1, and other components are the same.

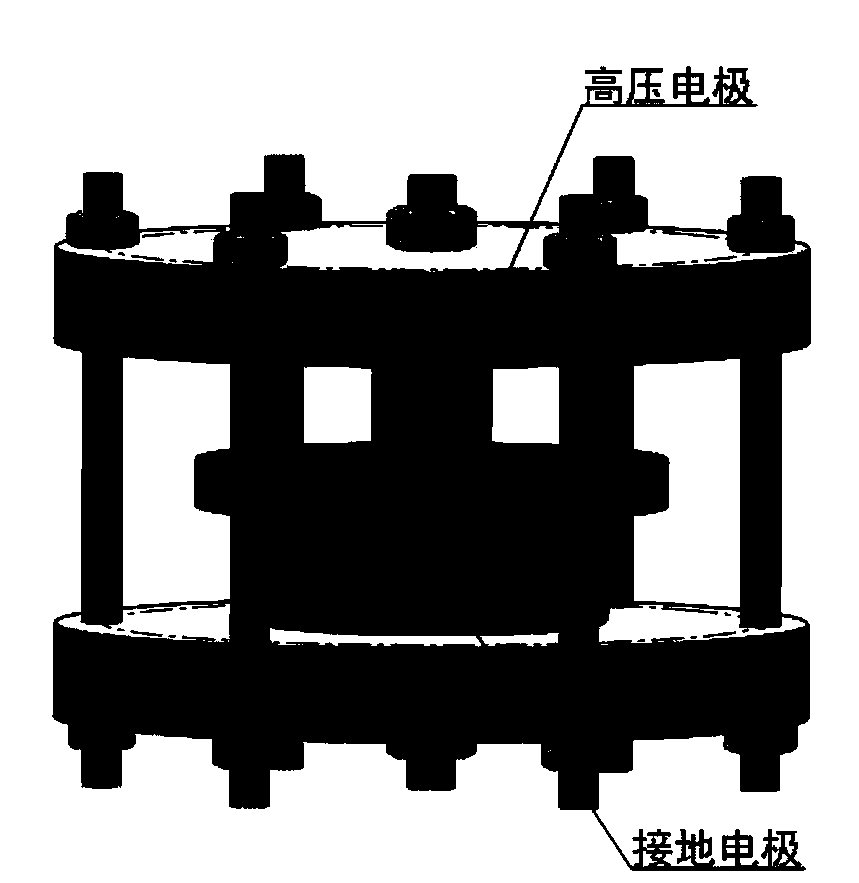

[0050] Figure 4 It is a schematic diagram of a ring-shaped electrode according to an embodiment of the present invention. Such as Figure 4 As shown, the high-voltage electrode adopts a ring structure, the ground electrode adopts a rod or ring structure and is connected to an insulating cooling member (cooling mechanism), the high-voltage electrode is located outside the ground electrode, and the test sample is located between the high-voltage electrode and the ground electrode. The test sample is cooled by conduction of the ground electrode; the whole device is used to test the surface electrical characteristics, breakdown withstand voltage characteristics and surface flashover characteristics of sheet or film samples. There are one or more high-voltage electrodes. Specific...

Embodiment 3

[0052] In the embodiment of the present invention, only the structure of the high-voltage electrode and the ground electrode is different from that in Embodiment 1, and other components are the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com