Air fixed point sampler and sampling method

A fixed-point sampling and air technology, which is applied to sampling devices and other directions, can solve the problems of small reference and irregular discharge time, and achieve the effects of low cost, easy management and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

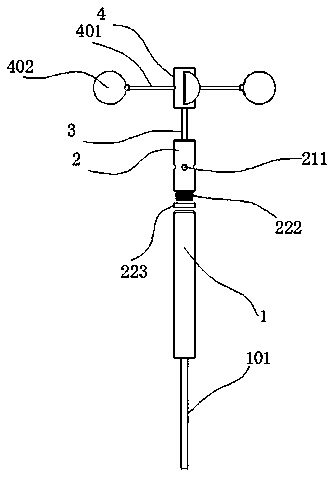

[0029] Such as figure 1 and figure 2 The air fixed-point sampler shown includes a test tube 1 for storing samples. The test tube 1 is made of plastic material, and an insertion rod 101 is formed by injection molding at the lower end of the test tube 1. The test tube 1 is transparent, which is convenient for each test tube. Check the extraction of particulate matter in the air every 10 to 20 days. There is a detachable air inlet pipe 2 above the test tube 1. The air inlet pipe 2 and the test tube 1 are detachable, which is convenient for later extraction from the test tube 1. The particulate matter is sent for inspection. A shaft 3 is inserted into the upper axis of the air inlet pipe 2, and a bearing 301 is installed between the shaft 3 and the air inlet pipe 2. In this embodiment, the bearing 301 adopts It is a roller bearing. An outer tube 4 is arranged on the upper end of the rotating shaft 3. The thickness of the outer tube 4 is 0.25 mm. A plurality of arms 401 are forme...

Embodiment 2

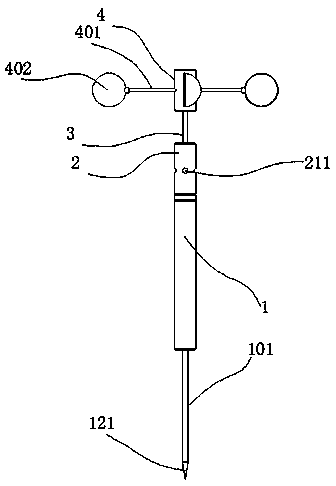

[0032] refer to image 3 As shown, the insertion rod 101 is a solid structure, and the lower end of the insertion rod 101 is injection-molded to form a cylindrical spike 121. When fixing the product, select a soil layer for placement, and insert it downward through the spike To the ground, the depth of the insertion rod inserted into the ground is 15cm~20cm, and the diameter of the insertion rod is 8mm~12mm; the design purpose of the insertion rod is to facilitate the installation of this product on the earthy ground, and the installation is easier easy.

Embodiment 4

[0034] refer to Figure 4As shown, the test tube 1 is filled with filter cotton 131 for capturing particles. The filter cotton is designed to passively capture particles in the air. When the air enters the test tube, the particles can be collected through the filter cotton.

[0035] Wherein, the filter cotton 131 is a medium-efficiency filter cotton.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com