An Objective Evaluation Method of Diesel Engine Impulse Noise

An objective evaluation method, diesel engine technology, applied to internal combustion engine testing, measurement of ultrasonic/sonic/infrasonic, instruments, etc., can solve the problems of evaluation confusion, inconsistent standards, relying on subjective evaluation, etc., and achieve low background noise interference and good consistency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

[0049] see Figure 1-8 .

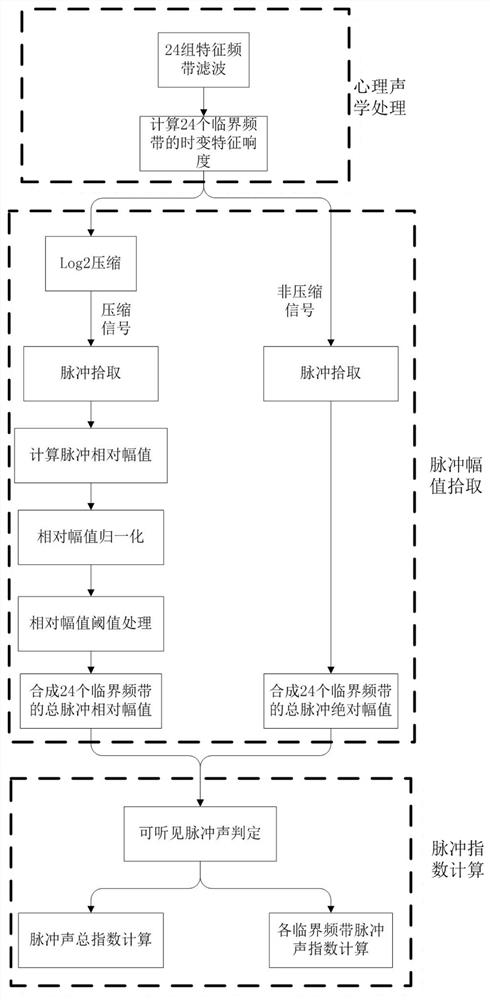

[0050] The present invention discloses that in order to achieve the purpose of the present invention, the technical solution adopted in the present invention is: an objective evaluation method of diesel engine pulse noise, and the specific steps are as follows:

[0051] Step 1: A sound signal is filtered by 24 groups of critical band filters in the range of 20-16000 Hz to obtain 24 groups of sound pressure signals, and the time-varying characteristic loudness of each group of signals is calculated considering the masking effect in the frequency domain and time domain. Finally, 24 sets of characteristic loudness time series of the sound signal in 24 critical frequency bands are obtained, referred to as uncompressed signals;

[0052] Step 2: The pulse sound calculation and identification process is divided into two parallel signal proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com