Waste silicon sludge granulation forming silicon particle conveying and drying method and device

A drying method and technology of a drying device, which is applied in the field of drying and solid material transmission, can solve the problems of high labor intensity, high production cost, and low efficiency, and achieve good drying effect, improved ball forming rate, and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

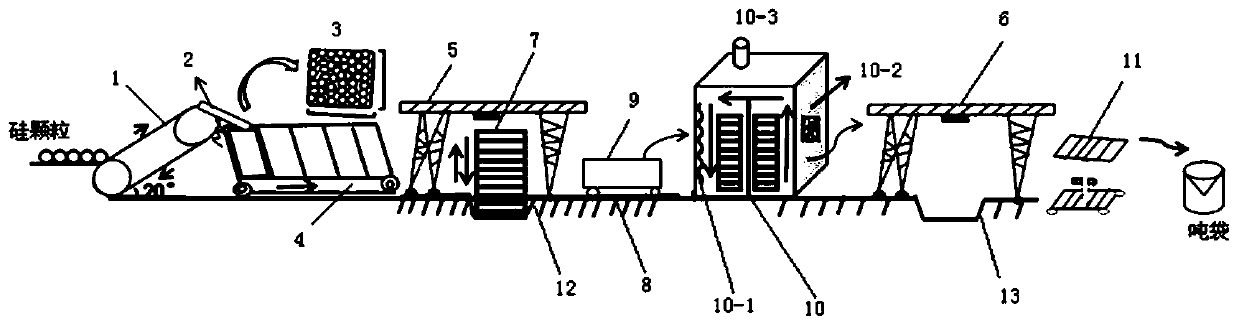

[0032] Such as figure 1 As shown, a transmission and drying device for granulating silicon particles from waste silicon mud, including a belt conveyor 1, a buffer plate 2, a material tray 3, a conveyor belt 4, a loading crane 5, a discharging crane 6, and a material rack 7 , Ground guide rail 8, hydraulic tractor 9, drying room 10, overturning type blanking device 11. Wherein the belt conveyor 1 is installed obliquely upward, and the buffer plate 2 is installed obliquely downward between the belt conveyor 1 and the conveyor belt 3 . Feeding pit groove 12 is set between conveyer belt 3 and ground guide rail 8, and feeding row crane 5 is just installed on the top of feeding pit groove 12. The hydraulic tractor 9 is installed on the ground guide rail 8, and the ground guide rail 8 extends through the drying room 10 to the discharge pit 13. The top of the unloading pit 13 is installed with an unloading line crane 6, and the overturning type unloading device 11 is installed behin...

Embodiment 2

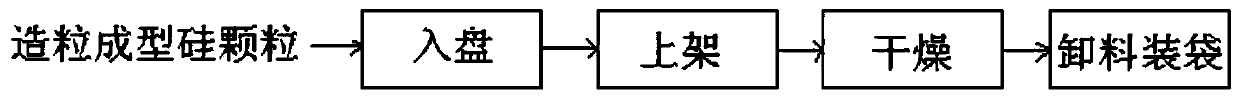

[0040] like image 3 As shown, the transfer and drying methods of granulated and formed silicon particles from waste silicon mud mainly include the steps of loading into trays, racking, drying, unloading, and bagging, as follows:

[0041] Step 1: Enter the disk

[0042] The granulated silicon particles (3-5 cm in diameter) are conveyed in batches to a height of 1.1-1.2 m above the ground through a belt conveyor, and then slide down through the buffer plate to the empty material tray placed on the conveyor for receiving silicon particles middle.

[0043] Step 2: Put it on the shelves

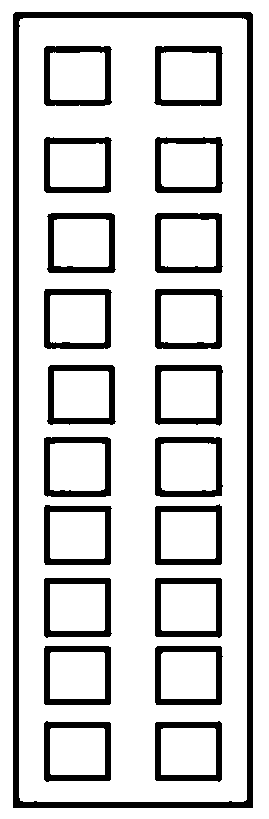

[0044] Manually assist the silicon particles in the material tray to be stacked in double layers (the stacking density is 0.7~0.8 g / cm 3 . ), the stacked material trays are conveyed by stainless steel roller conveyors. The end of the conveyor is the feeding pit. The height of the material rack in the feeding pit is adjusted by the lifting of the feeding crane, and the material tray with a to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com