Automated sock turn-over and end sewing device capable of moving downwards-turned stocking cylinder in multiple directions and application method

A multi-directional, sewing head technology, applied in the field of textile machinery, can solve the problems of reduced work efficiency, machine wear and loss, etc., and achieve the effect of convenient and stable operation, high degree of automation, and reduced failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to deepen the understanding of the present invention, the invention will be further described in detail below in conjunction with the examples and accompanying drawings. The examples are only used to explain the present invention and do not constitute a limitation to the protection scope of the present invention.

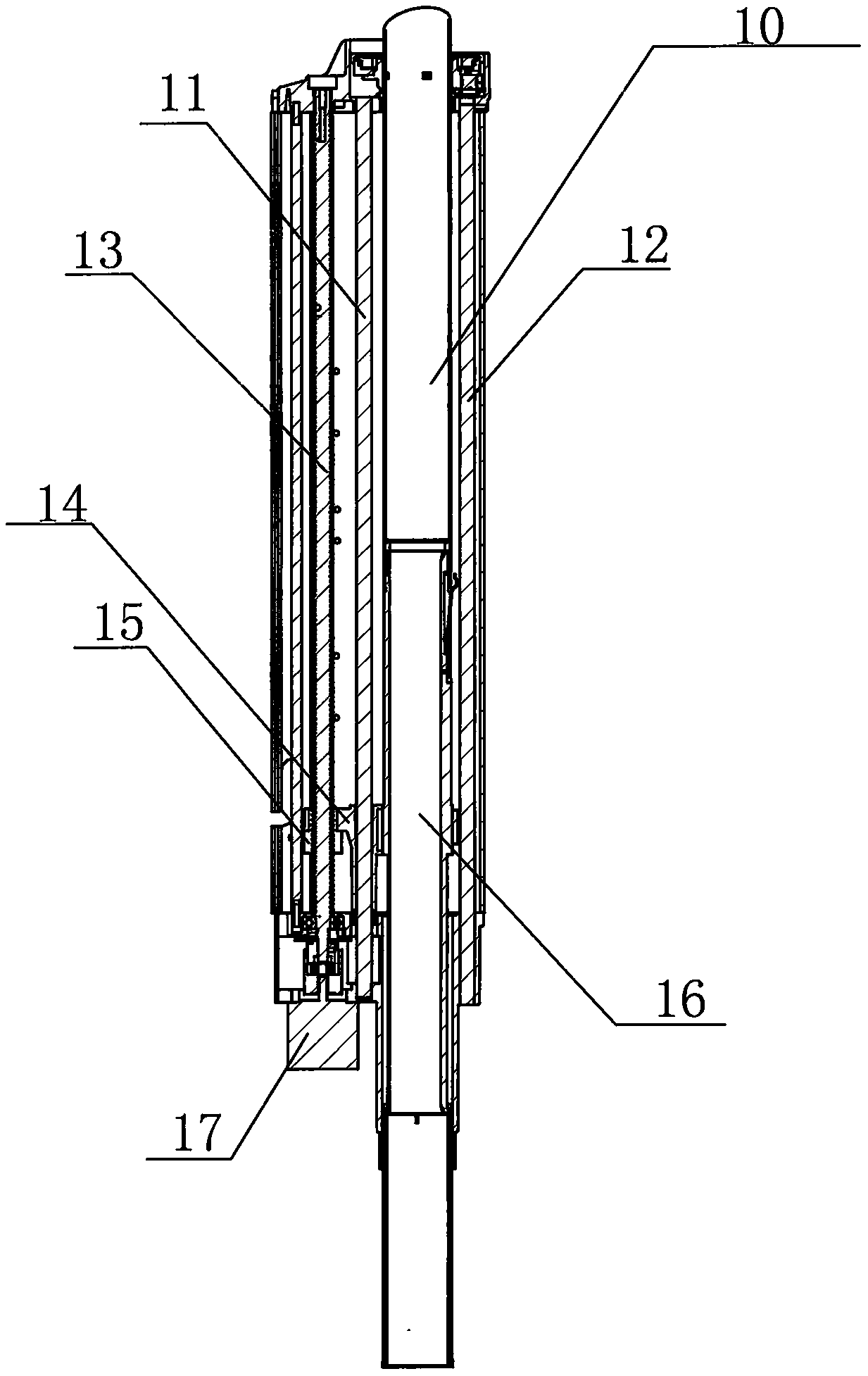

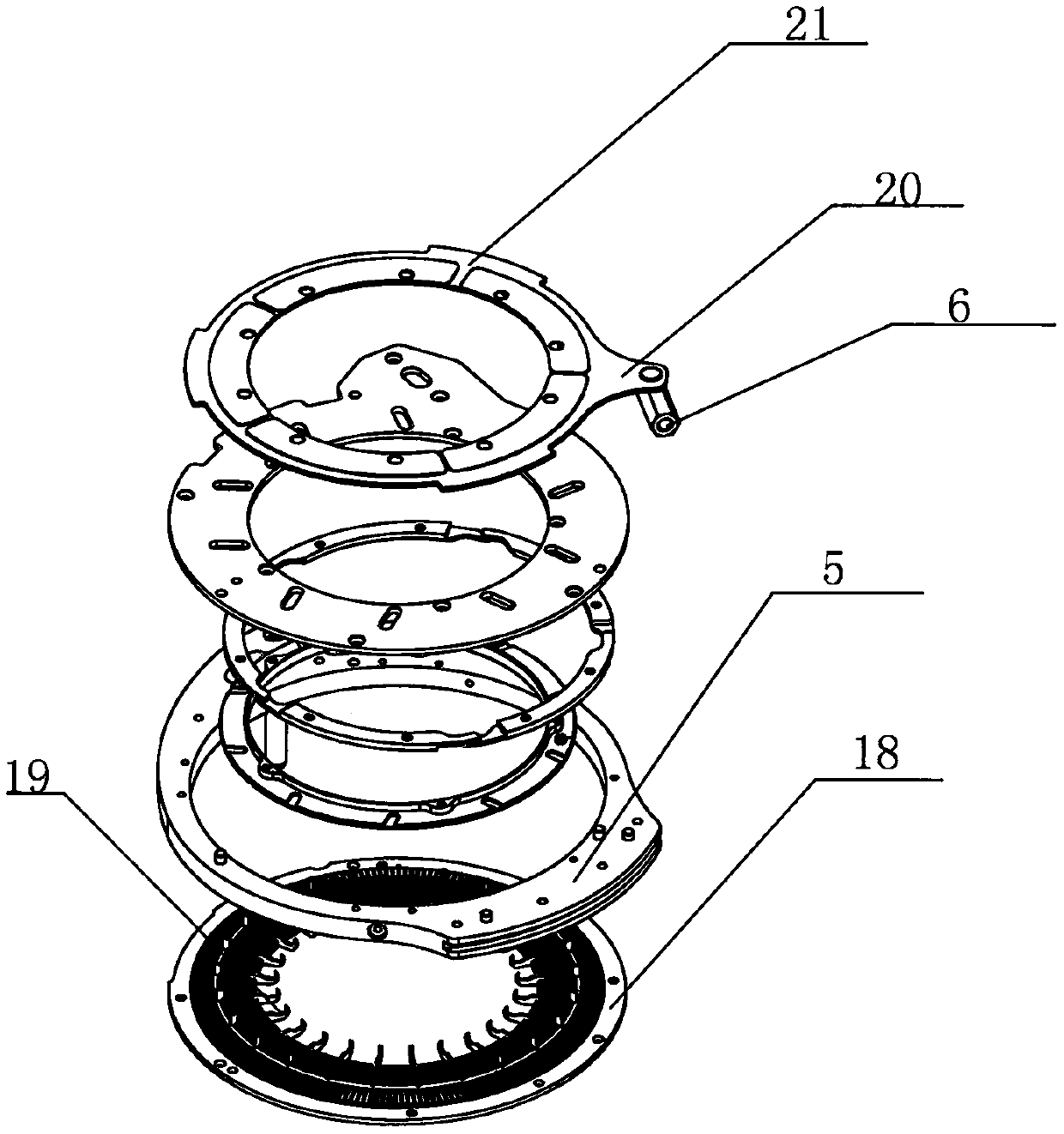

[0028] like Figures 1 to 6 Shown is an automatic sock-turning seam device with multi-directional movement of the bottom-turning sock tube, including a sock-knitting device, a sock-turning device, a seam head device and a seam plate 3, and the sock-knitting device and the seam plate 3 are installed There is a mechanical swing arm, and the mechanical swing arm grabs one end of the sock tube on the sock knitting device located below it, and swings it horizontally to the 3 sewing discs above the mechanical swing arm. The sock tube 1 is moved to the other end of the sock tube through the driving mechanism. There is a suction port on the top of the down-t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com