A microwave plasma diamond film deposition equipment

A technology of microwave plasma and diamond film, which is applied in the direction of metal material coating process, coating, gaseous chemical plating, etc., can solve the problems of high vacuum leakage rate, lower product quality, and smaller compression of MPCVD equipment, and meet the requirements of The effect of scientific research and industrial production needs, improvement of product quality, and reduction of vacuum leak rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

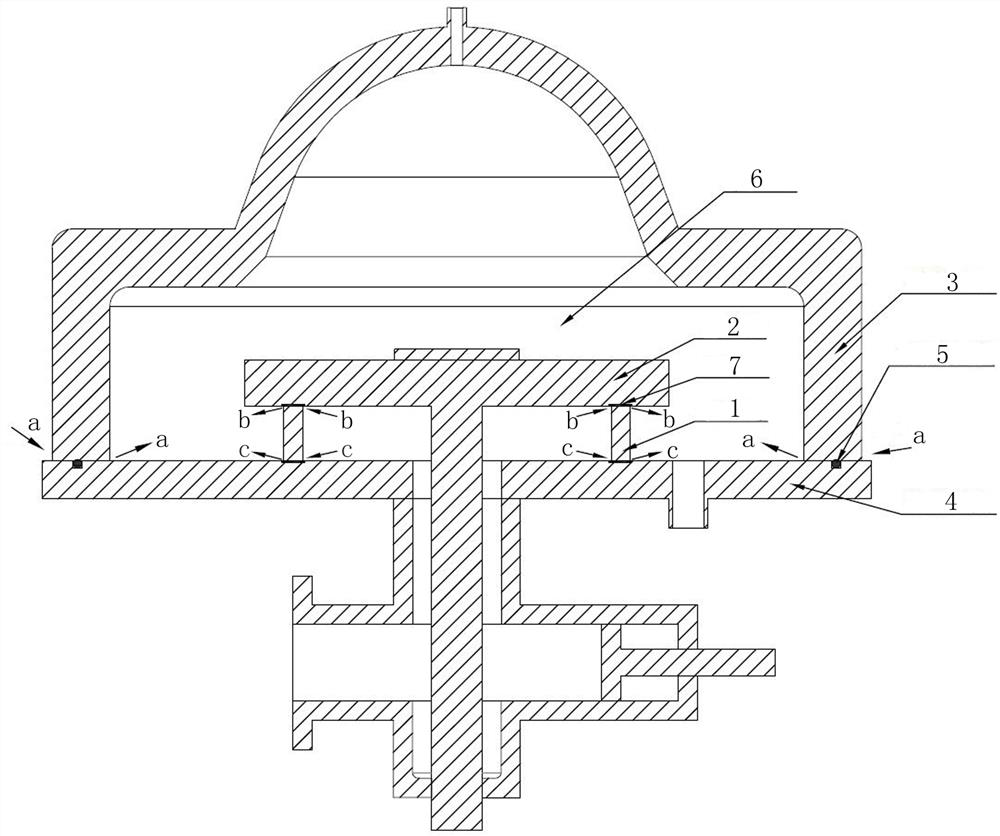

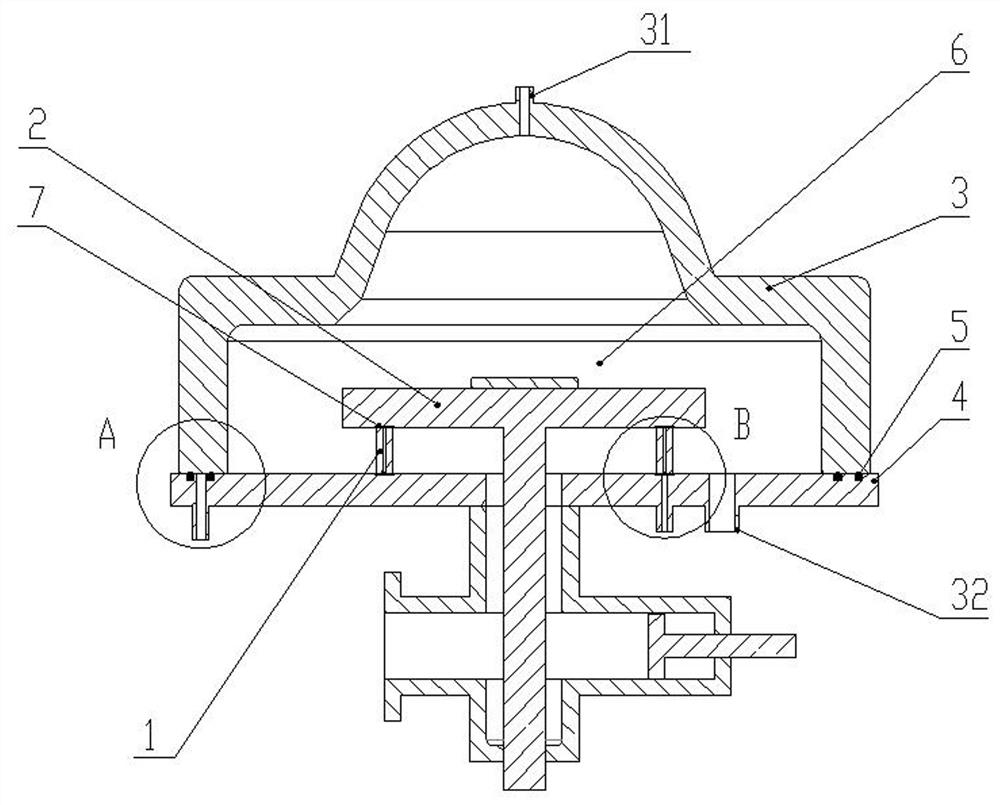

[0023] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

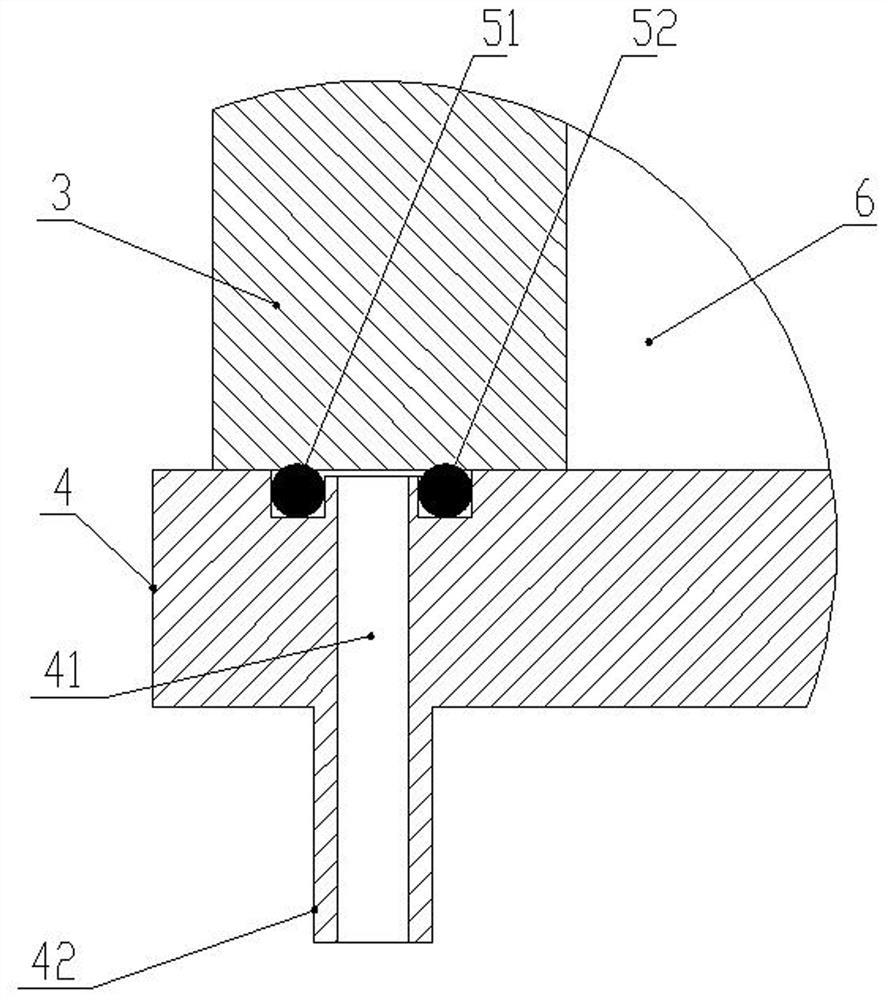

[0024] Such as Figure 2 to Figure 4 Shown, a kind of microwave plasma diamond film deposition equipment, comprises upper cover plate 3, base plate 4 and the reaction chamber 6 that is surrounded by both, is provided with air inlet 31 on the top of upper cover plate 3, is used for diamond film The prepared process gas enters the reaction chamber 6, and the bottom plate 4 is provided with a pumping port 32, and the pumping port 32 is connected to a vacuum device to pump the reaction chamber 6 into a vacuum environment. The connection between the bottom plate 4 and the upper cover plate 3 is sealed by an O-ring group 5, and the O-ring group 5 includes an outer sealing ring 51 and an inner sealing ring 52 arranged in concentric circles. The ring group 5 is set in the first sealing groove on the bottom plate 4, and the two rings of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com