Laser sample observation window capable of replacing window glass

A sample observation and laser technology, which is applied in the field of ultra-high vacuum laser sample observation window, can solve the problems of high-precision analysis, high background level of the system, micro-cracking of resin aging, etc., and achieve low background level and long service life , the effect of low vacuum leak rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

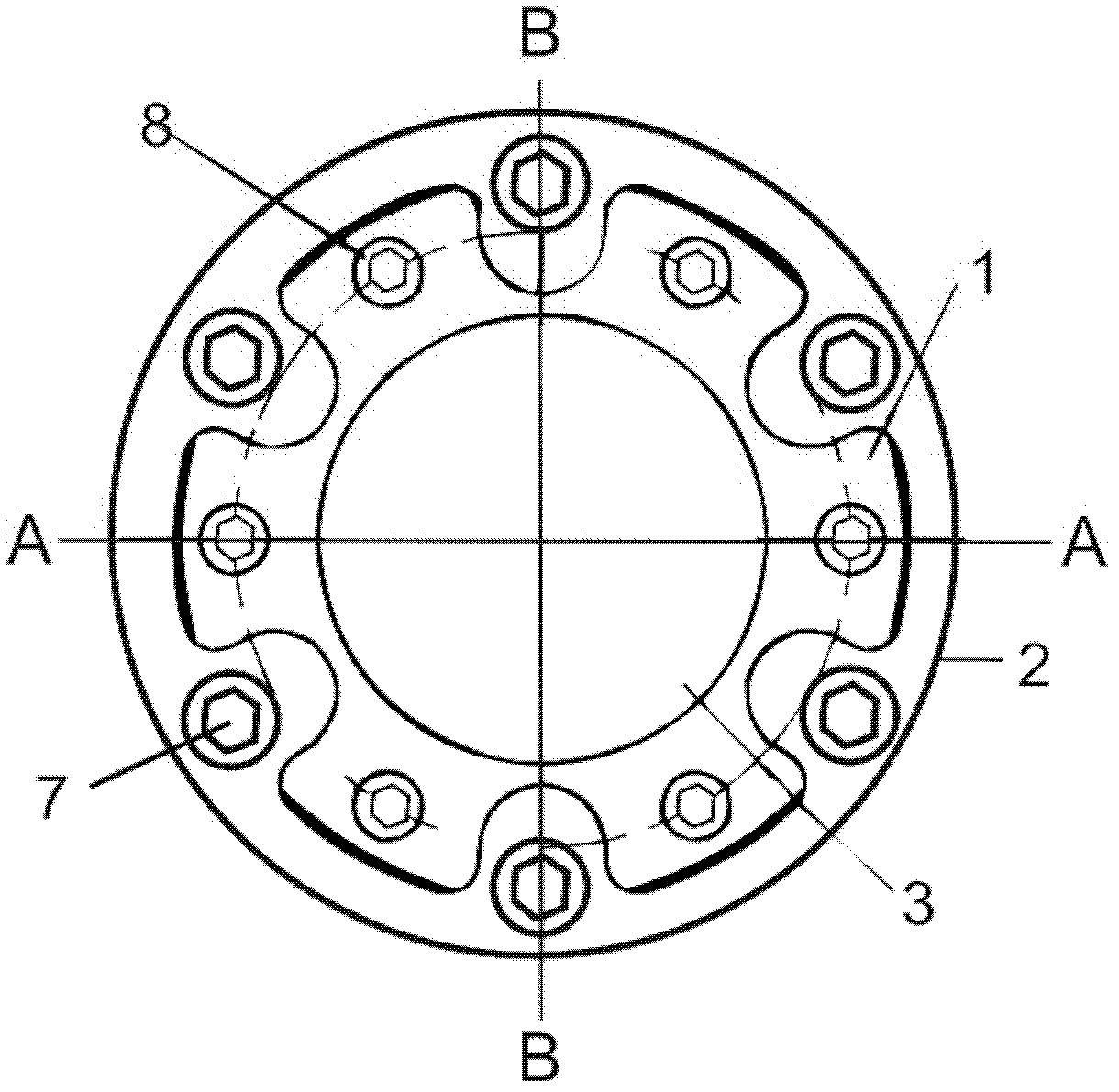

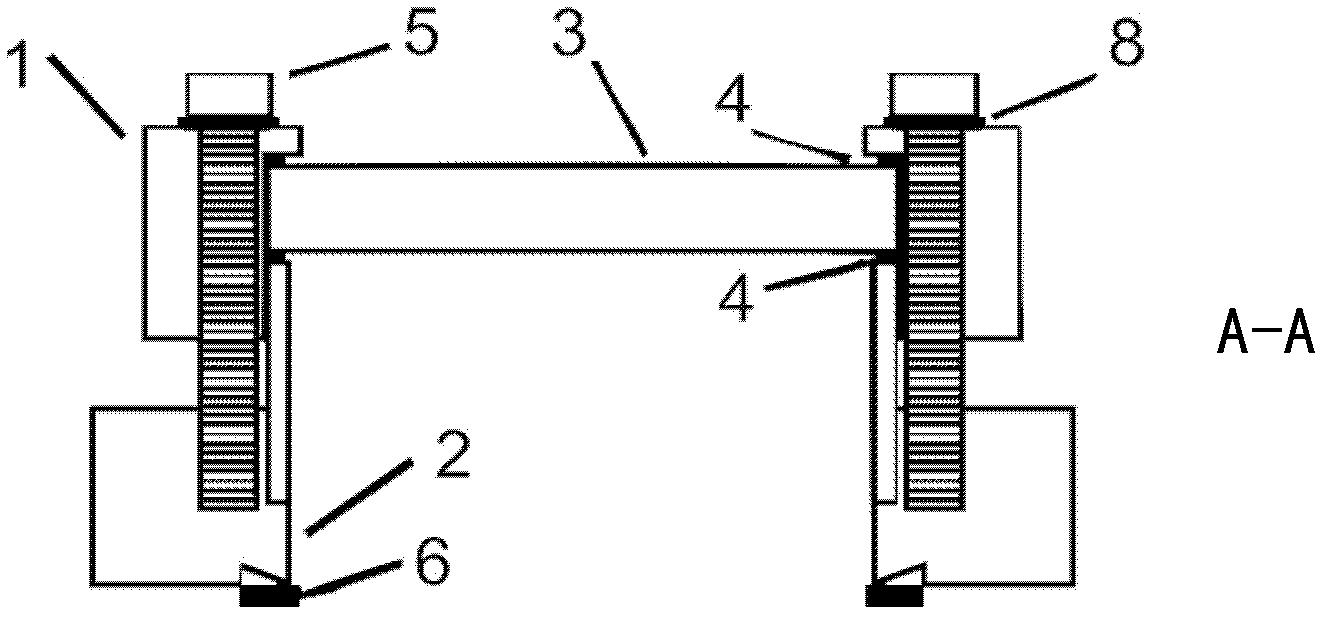

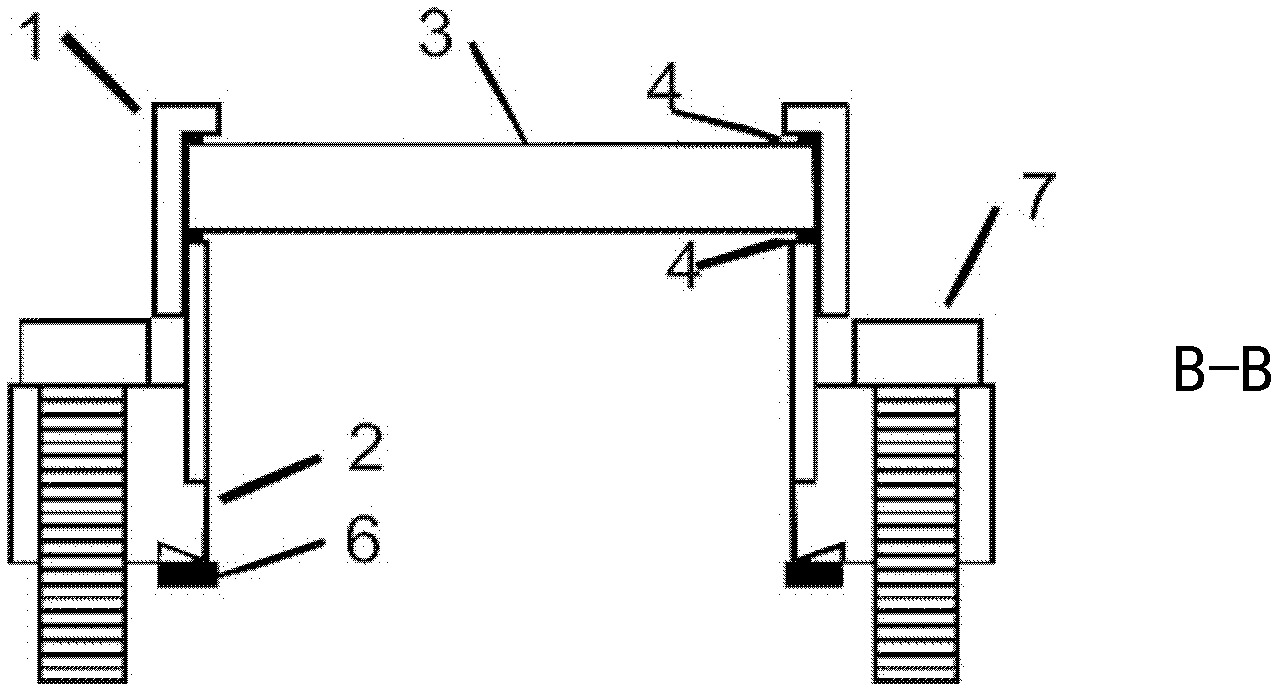

[0017] The ultra-high vacuum laser sample observation window with replaceable window glass of the present invention consists of two flanges (short tube CF flange and upper cover flange), light-transmitting crystal disc, Pb-Ag-Sn alloy sealing ring, inner Composed of hexagonal bolts, spring washers, etc.

[0018] The flange in the laser sample observation window is made of 316L stainless steel, and the CF flange design of the inner welded short tube effectively reduces the influence of flange stress changes on the sealing performance between the crystal and stainless steel, prolonging the life of repeated use.

[0019] The light-transmitting crystal disc is made of zinc sulfide or zinc selenide crystal, suitable for 10.6 micron wavelength laser penetration. No coating or no coating on the edge to prevent the uneven coating on the edge from affecting the sealing performance of the crystal and the gasket.

[0020] The Pb-Ag-Sn alloy is composed of 97% Pb, 1.5% Ag, and 2.5% Sn (w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com