All-fiber current transformer and all-fiber current transformer unit

A current transformer, all-fiber technology, used in the measurement of current/voltage, voltage/current isolation, instruments, etc., can solve the problems of complex structure and low assembly efficiency of current transformers, so as to solve the problem of low assembly efficiency and improve installation. Efficiency, the effect of reducing installation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

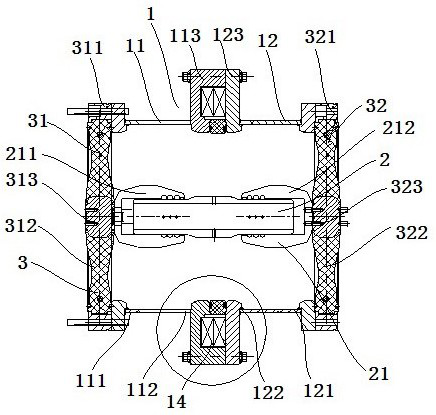

[0053] like figure 1 and figure 2 As shown, the all-fiber-optic current transformer unit includes an all-fiber-optic current transformer 1 , a central conductor 2 and an end insulator 3 .

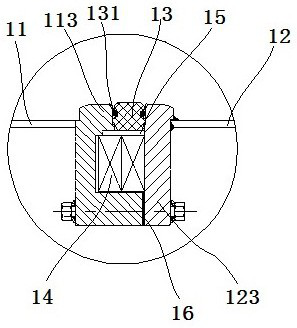

[0054] The all-fiber current transformer 1 includes a first cylinder 11 , a second cylinder 12 , an insulating ring 13 and a sensing ring 14 .

[0055] The first cylinder 11 has a first cylinder external end 111 and a first cylinder butt end 112, the second cylinder 12 has a second cylinder external end 121 and a second cylinder butt end 122, and the first cylinder external end 111 and the second barrel external end 121 are both connected to the external switchgear barrel, and the first barrel butt end 112 is detachably connected to the second barrel butt end 122 .

[0056] An annular block 113 is provided at the end of the first cylindrical body butt end 112, and an annular block 113 is provided with a groove opening toward the second cylindrical body butt end 122. The end of the second...

specific Embodiment 2

[0068] The only difference from the all-fiber-optic current transformer unit in Embodiment 1 above is that the cavity and the annular plate are fixedly connected by means of screw connection. In other embodiments, the metal ring and the external flange may also be connected by screws.

specific Embodiment 3

[0070] The only difference from the all-optical current transformer unit in the above-mentioned embodiment 1 is that the butt end of the first cylinder and the butt end of the second cylinder are both grooves, and the two grooves can be butted to form a sensor for the sensor ring to be placed in. Induction ring housing chamber. In other embodiments, the butt end of the first cylinder and the butt end of the second cylinder are in the shape of "L" and "7", and the abutment can form a sensing ring accommodating cavity for the sensing ring to be placed in.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com