Dynamic cyclic ultrasound rapid aging accelerating and on-line wine ripening monitoring method

A dynamic circulation, wine technology, applied in the field of wine brewing, can solve the problems affecting aroma substances and taste characteristics, increase labor intensity, and increase the temperature of wine body, so as to reduce the loss of oxidation and volatile components, reduce labor intensity, avoid The effect of overprocessing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

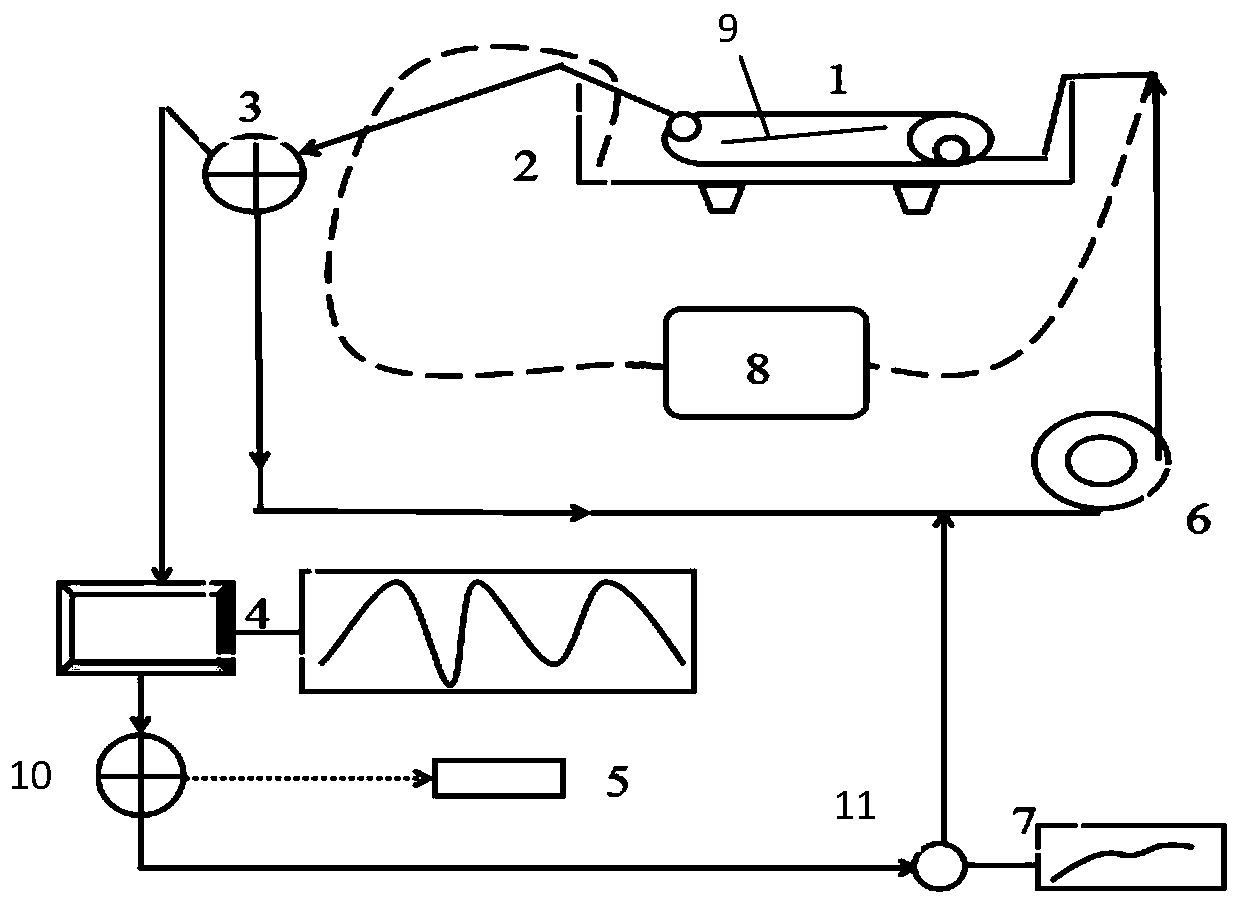

[0048] see figure 1 , the present invention's system for rapid aging and online monitoring of wine maturation by dynamic circulation ultrasound includes ultrasonic treatment tube 1, oak chips 9, ultrasonic treatment tank 2, first diverter valve 3, ultraviolet-visible spectrophotometer 4, chromatographic analyzer 5 , the second diverter valve 10, the peristaltic pump 6, the conductivity meter 11, the temperature measuring sensor 8 and the master control machine 7, wherein the ultrasonic treatment tube 1 includes a tube body, a screw cap, a filter screen and a pipe joint, and the tube body adopts glass Pipes or transparent plastic pipes, etc., screw caps are installed at both ends of the tube body, and a pipe joint that can connect the inside and outside of the pipe body is interspersed on the screw cap, and a filter screen is installed on the inner side of the screw cap to control the liquid entering and leaving the pipe joint. to filter. The oak chip 9 is placed in the inner ...

Embodiment 2

[0057] The system of dynamic cycle ultrasonic rapid aging and on-line monitoring of wine maturation in this embodiment includes an ultrasonic treatment tube 1, oak chips 9, an ultrasonic treatment pool 2, a first diverter valve 3, an ultraviolet-visible spectrophotometer 4, a peristaltic pump 6, Conductivity meter 11, temperature measuring sensor 8 and master control machine 7, wherein, ultrasonic processing tube 1 comprises circular tube body, screw cap and filter screen and pipe joint, and tube body adopts glass tube or transparent plastic tube, and in the two sides of tube body Screw caps are respectively installed at the ends, and a pipe joint capable of connecting the inside and outside of the pipe is interspersed on the screw cap, and a filter screen is installed on the inner side of the screw cap to filter the liquid entering and leaving from the pipe joint. The oak chip 9 is placed in the inner cavity of the ultrasonic treatment tube 1 and immersed in the wine liquid. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com