Non-woven fabric bag trepanning machine

A technology of non-woven bags and hole opening machines, which is applied in bag making operations, container manufacturing machinery, paper/cardboard containers, etc. It can solve the problems of hole position deviation, waste of resources, low production pass rate, etc., and achieve volume control Precise, accurate hole position, prevent over processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

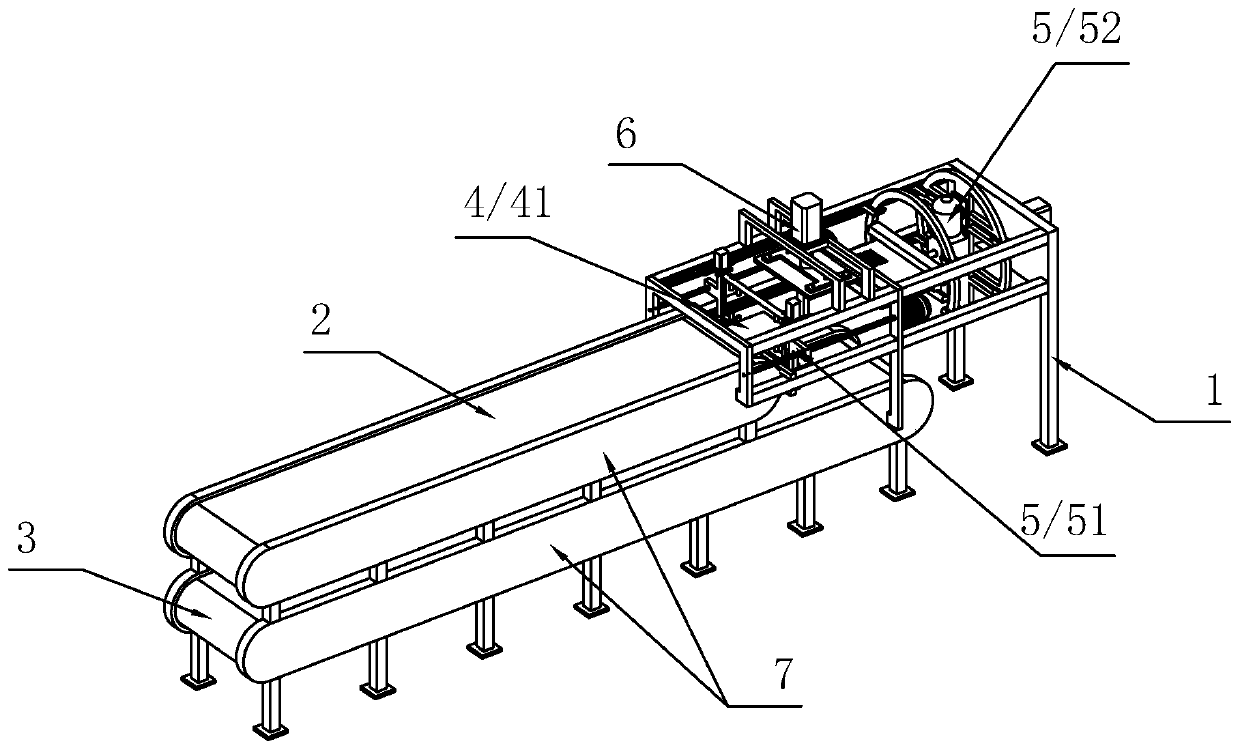

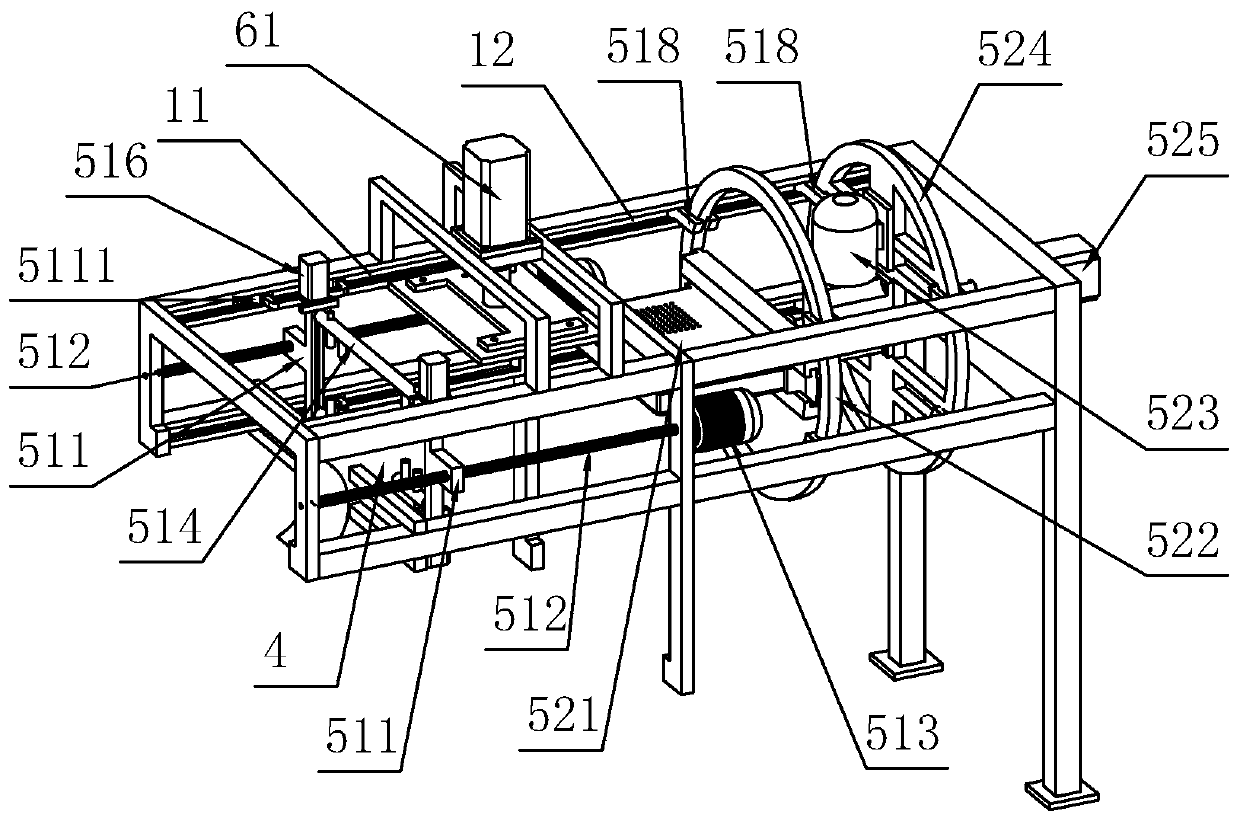

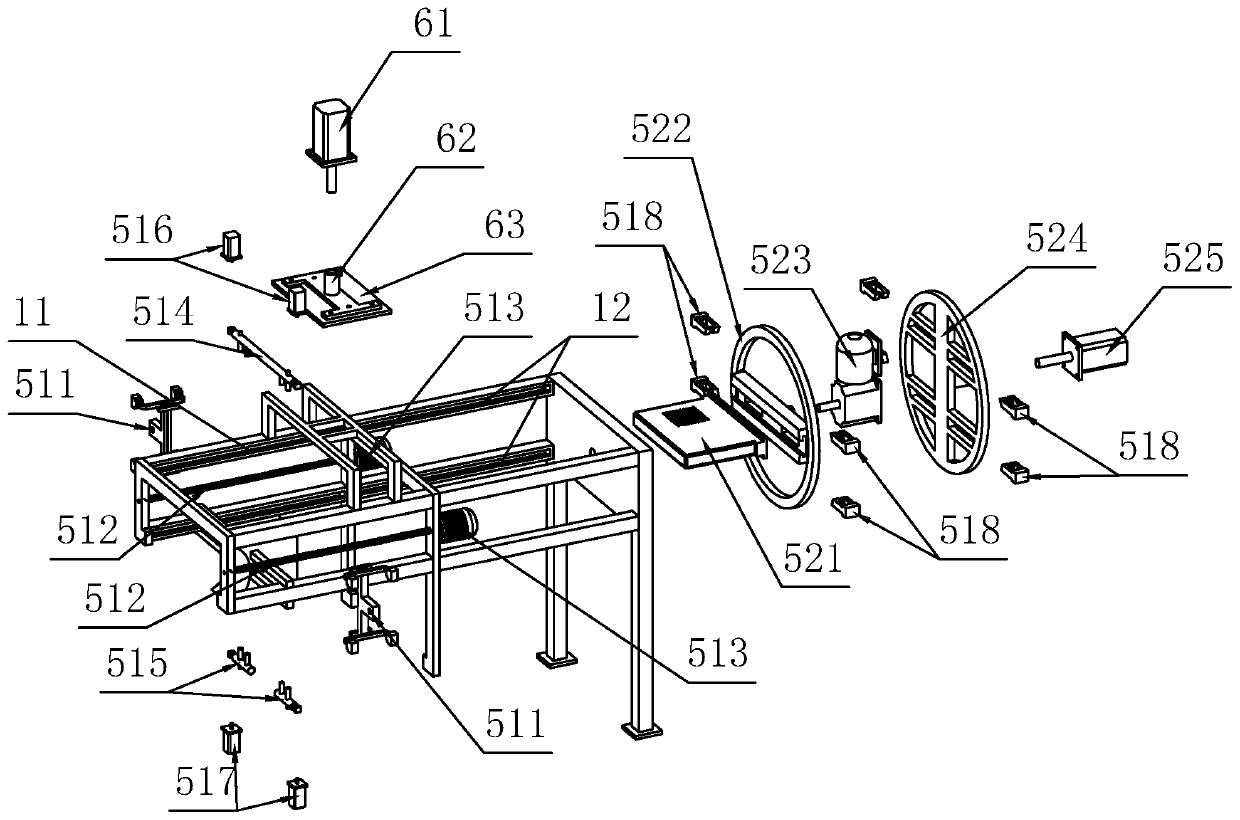

[0032] Such as Figure 1-Figure 3 As shown, the present invention discloses a non-woven bag opening machine, comprising a frame 1 constructed of rods, on which a feeding conveyor belt 2, a discharging conveyor belt 3, a feeding platform 4, a bag The body stretching mechanism 5 and the opening mechanism 6, the feeding conveyor belt 2 is extended from left to right (the transmission direction is from left to right), and the feeding platform 4 is set on the frame by screwing with the frame 1 1 is located on the right side of the feeding conveyor belt 2, and is provided with a feeding plane 41 on the upper surface of the feeding platform 4, so that the non-woven bags that have been bagged are placed on the left side of the feeding conveyor belt 2 in an orderly manner....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com