Dust-free environment-friendly calcium-zinc compound stabilizer as well as preparation method and application thereof

A calcium-zinc composite and stabilizer technology, applied in the field of chemical stabilizers, can solve problems such as the inability to meet market demand and the immature performance of calcium-zinc stabilizers, and achieve the effects of preventing migration and precipitation, improving performance and shortening the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

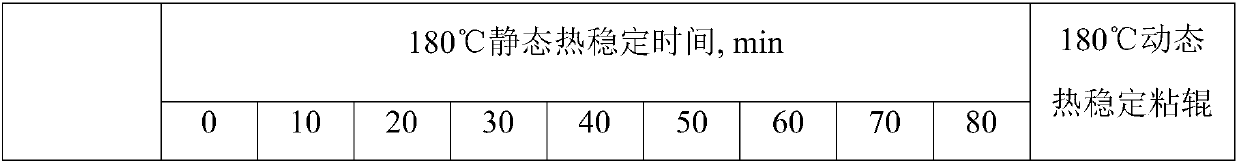

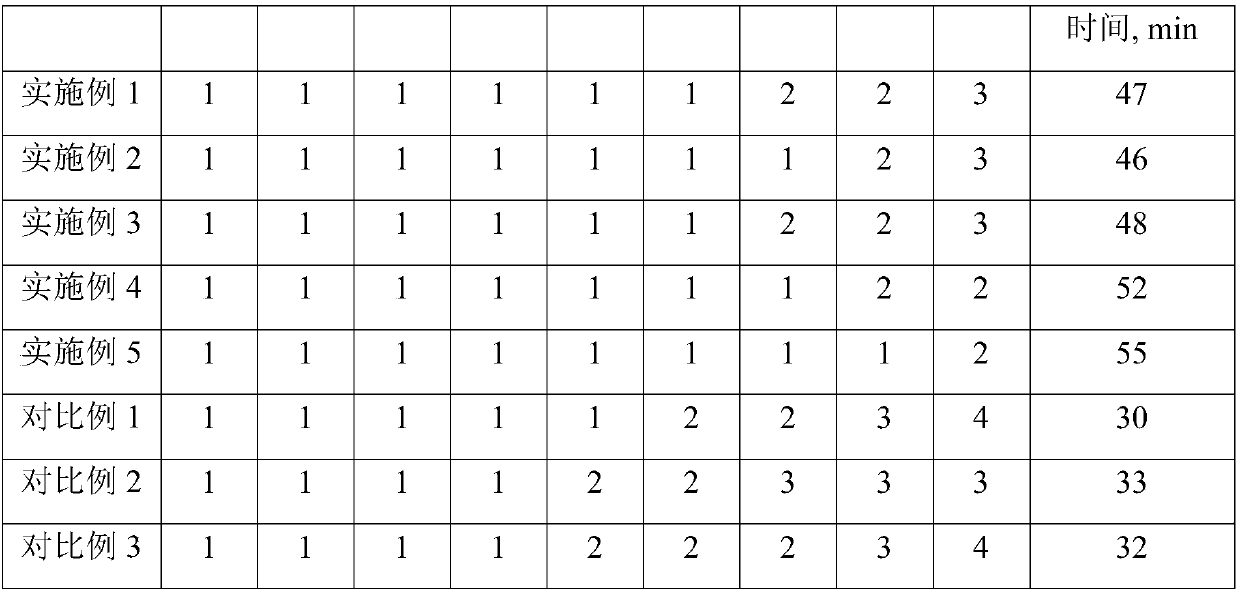

Examples

Embodiment 1

[0059]This embodiment provides a dust-free and environmentally friendly calcium-zinc composite stabilizer, which is composed of the following raw materials in mass percentage: stearic acid: 50%, zinc oxide: 1.5%, calcium oxide: 6.5%, calcium acetylacetonate: 10%, PE Wax: 8%, β-diketone: 4%, non-toxic phosphite: 5%, antioxidant: 6%, enhancer: 9%; the average particle size of ultrafine zinc oxide is 30nm; the ultrafine calcium oxide The average particle size is 40nm, the non-toxic phosphite is 4,4-diisoylidene bisphenol (12-14) carbon alkyl ester of phosphite; the antioxidant is antioxidant 1010, and the reinforcing agent is calcium carbonate;

[0060] The preparation method of the above-mentioned dust-free and environment-friendly calcium-zinc composite stabilizer specifically comprises the following steps:

[0061] S1. Stearic acid, zinc oxide and calcium oxide are mixed according to the above ratio, and then calcium stearate and zinc stearate are synthesized under the catalys...

Embodiment 2

[0064] This embodiment provides a dust-free and environmentally friendly calcium-zinc composite stabilizer. The main difference from Example 1 is that it consists of the following raw materials in mass percentages: stearic acid: 58%, zinc oxide: 4.2%, calcium oxide: 3% , Calcium acetylacetonate: 6%, PE wax: 12%, β-diketone: 0.8%, non-toxic phosphite: 9%, antioxidant: 1%, enhancer: 6%; the average particle size of ultrafine zinc oxide The diameter is 80nm; the average particle diameter of superfine calcium oxide is 80nm;

[0065] The preparation method of the above-mentioned dust-free and environment-friendly calcium-zinc composite stabilizer refers to the operation steps of Example 1, the main difference is that in step S1, the amount of hydrogen peroxide is 8‰ of the mass of hard acid, the reaction temperature is 120°C, and the reaction time 10min.

Embodiment 3

[0067] This embodiment provides a dust-free and environmentally friendly calcium-zinc composite stabilizer. The main difference from Embodiment 1 is that it consists of the following raw materials in mass percentages: stearic acid: 52%, zinc oxide: 4%, calcium oxide: 4% , Calcium acetylacetonate: 7%, PE wax: 15%, β-diketone: 1%, non-toxic phosphite: 6%, antioxidant: 3%, enhancer: 8%; the average particle size of ultrafine zinc oxide The diameter is 50nm; the average particle diameter of superfine calcium oxide is 60nm;

[0068] The preparation method of the above-mentioned dust-free and environment-friendly calcium-zinc composite stabilizer refers to the operation steps of Example 1, the main difference is that in step S1, the amount of hydrogen peroxide is 5‰ of the mass of hard acid, the reaction temperature is 110°C, and the reaction time 15min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com