A method for preparing an exhaust duct

A technology for exhaust ducts and molds, which is applied to manufacturing tools, ceramic molding machines, etc., can solve problems such as high noise, pitted surfaces of exhaust ducts, and delamination, so as to reduce equipment damage, increase service life, and structural strength. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] Example 1 (Tilting Vibration Mode 1)

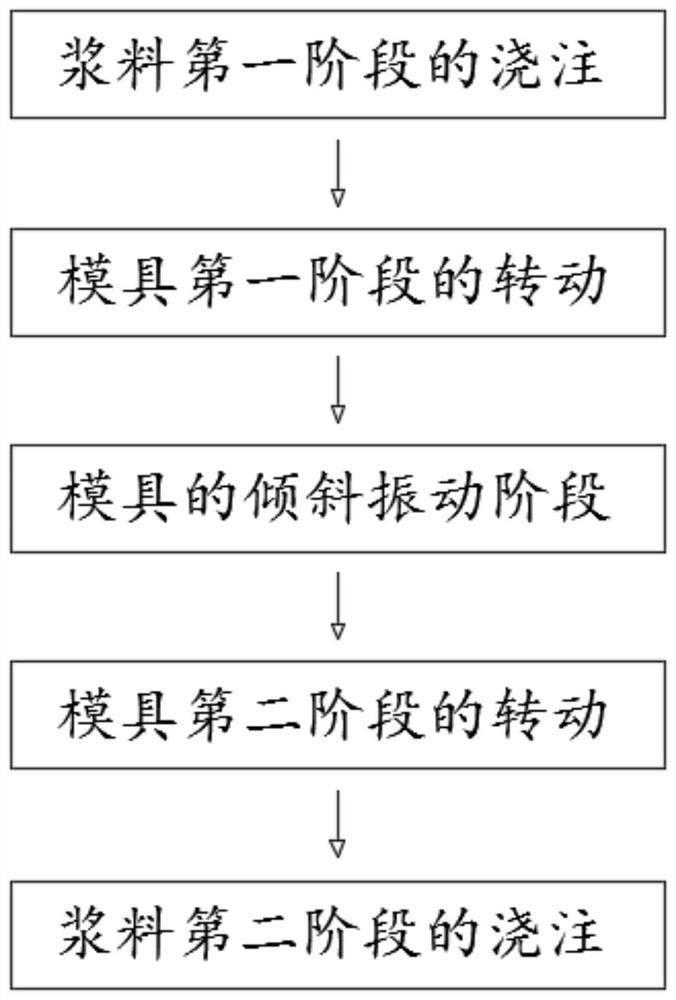

[0071] Such as figure 1 -8, a method of preparing an exhaust passage, after the mold positioning, processes:

[0072] Pouring of the first stage of the slurry:

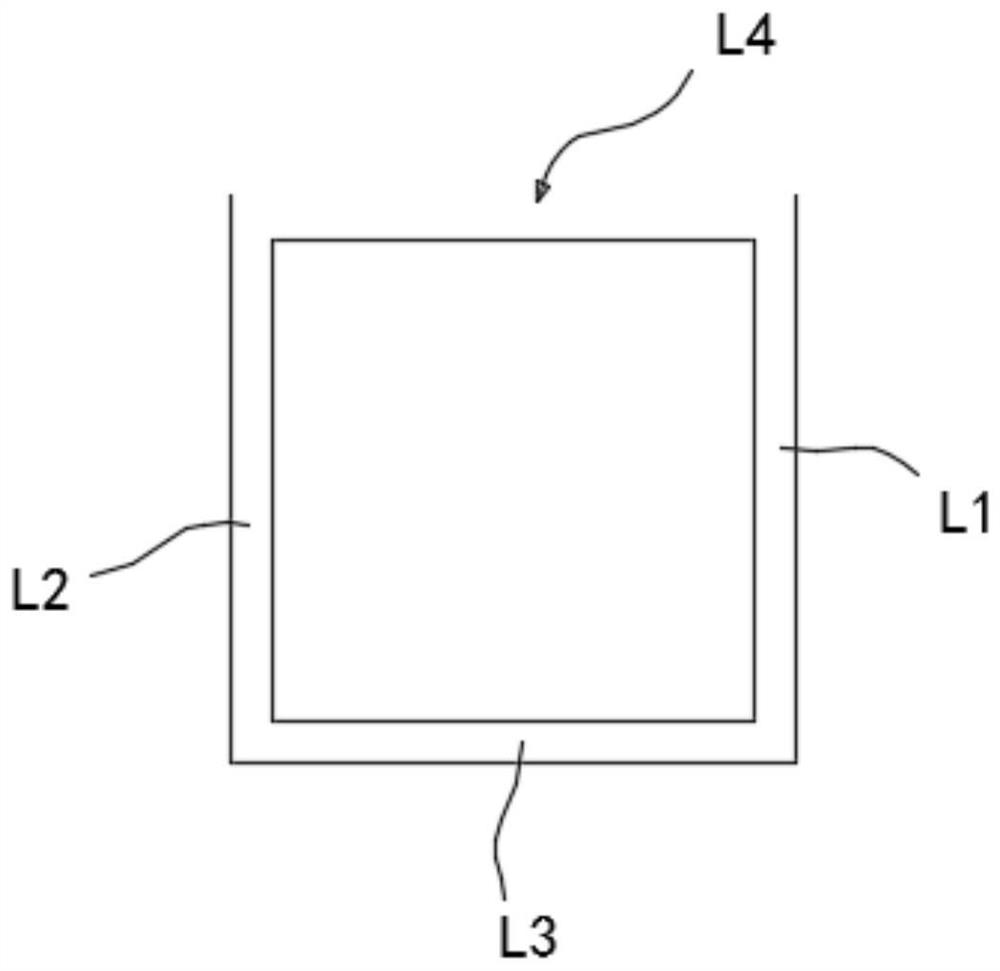

[0073] In the top region L4 of the mold, the slurry is dispersed into the first side region L1 and the second side side region L2, and aggregate in the bottom region L3, continuous pouring slurry to the slurry to fill the bottom Regional L3;

[0074] Preferably, during the casting of the first phase of the slurry, the amount of the dispersion flowing into the first side region L1 and the second side region L2 slurry is generally the same or close, and after the slurry is filled with the bottom area, the first There is a certain amount of slurry in the side area L1, and the second side side region L2.

[0075] Among them, during the casting process of the first phase of the slurry, the horizontal vibration of the mold can be performed, or the horizontal vibration of the mold m...

Embodiment 2

[0095] Example 2 (Tilting Vibration Mode 2)

[0096] Such as Figure 9 -16, a method of preparation of an exhaust tract, especially the preparation method of the mechanism exhaust trail, after the mold positioning, the process:

[0097] The rotation of the first phase of the mold:

[0098] When the mold is rotated around the first direction toward the first side region L5 to the inclined posture, at this time, a cylindrical β is formed between the bottom region L7 in the cavity.

[0099] Preferably, the size β having an inclination angle between the bottom region L7 and the horizontal plane is poured into a cavity, further, the magnitude β of 20 ° is 20 °, and the inclination size β of the present embodiment is 15 °. Compared with the tilt vibration mode of Example 1, the inclination angle in this embodiment is smaller and the vibration effect is more prominent.

[0100] Among them, after the mold is rotated to the inclinement posture, the first side portion L5 and the second side...

Embodiment 3

[0121] Example 3 (Tilting Vibration Mode 2)

[0122] A method of preparing an exhaust passage, the difference from Embodiment 2 is that the slope of the mold is also provided in the tilt of the mold:

[0123] The periodic swing process of the mold: the mold is rotated around the first direction or back to the first side area to change the size of the plane and the horizontal plane in which the bottom region in the cast cavity is placed, through multiple circulation The swing process is realized to completely discharge the gas in the bottom region (including gas in the bottom region slurry), to avoid ventilation of the vent side wall (especially the side walls of the molded cavity bottom region), etc. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com