Horn edge pressing device for electronic accessory machining

A technology of edge-holding device and accessories, which is applied in the direction of feeding device, positioning device, storage device, etc., to achieve the effect of improving work efficiency, increasing edge-holding efficiency, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

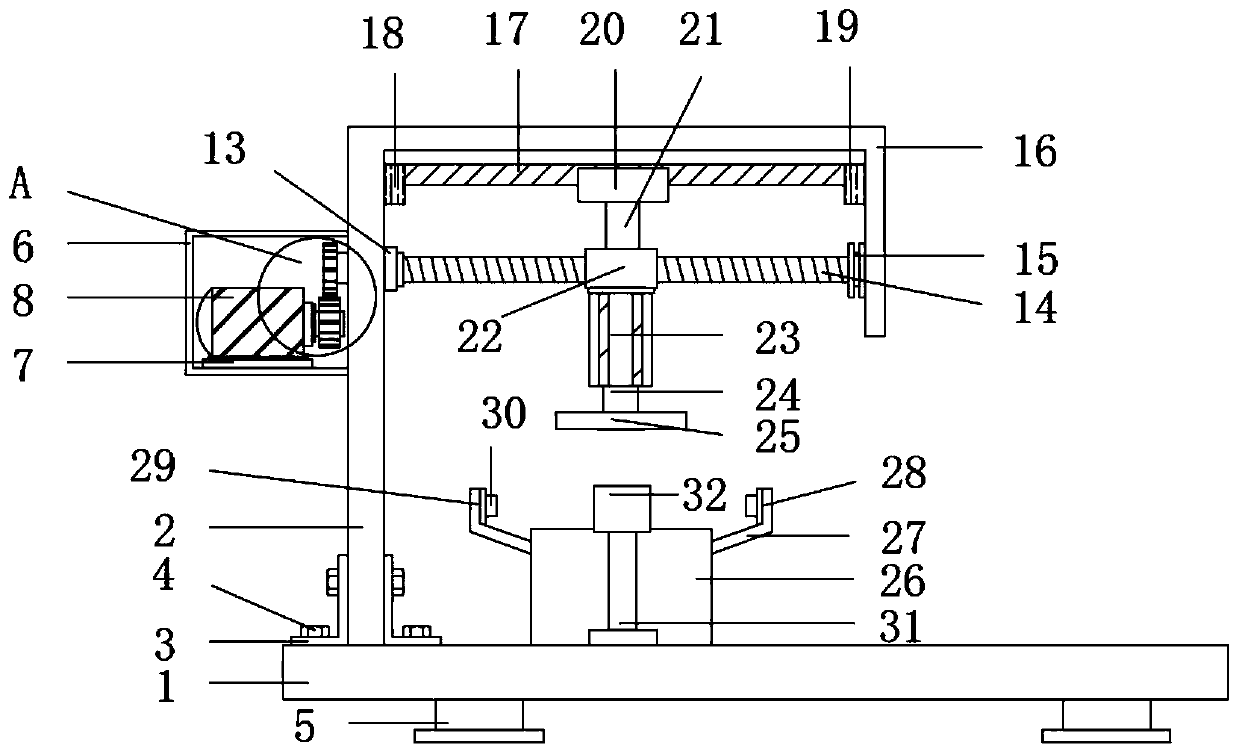

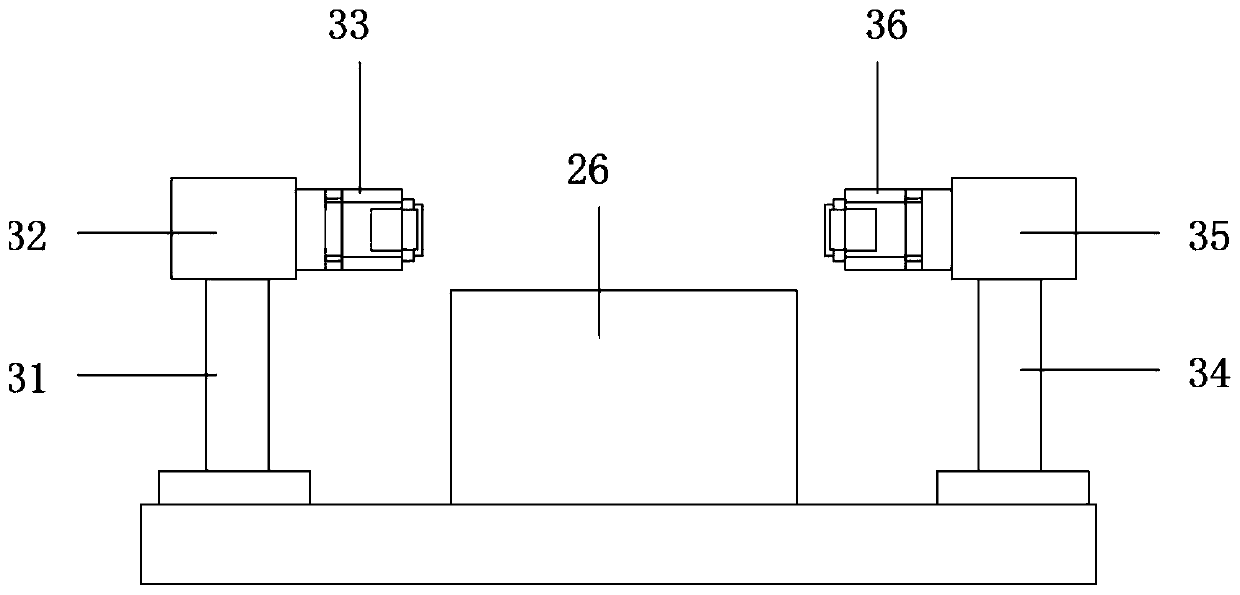

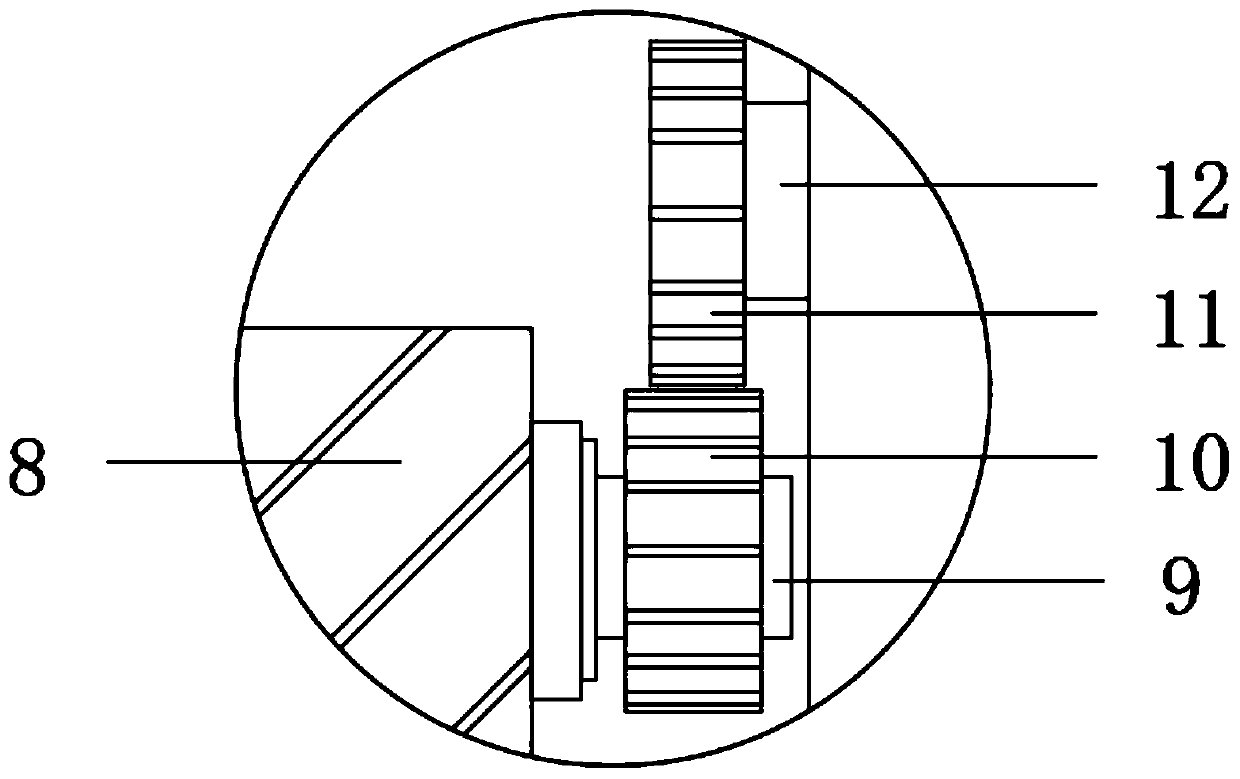

[0019] Such as Figure 1-3 As shown, this specific embodiment adopts the following technical solutions: a horn crimping device for processing electronic accessories, including a load-bearing base plate 1, and legs 5 are connected around the bottom of the load-bearing base plate 1, and the upper end of the load-bearing base plate 1 The center is fixedly connected with a placement platform 26, and the upper end of one side of the placement platform 26 is connected with a No. 2 fixed pole 29, and the upper end of the No. 2 fixed pole 29 is connected with a No. 2 camera 30 near the side of the placement platform 26. The placement table 26 is connected to a No. 1 fixed support rod 27 at the upper end on the other side away from the No. 2 fixed support rod 29, and the No. 1 fixed support rod 27 upper end is connected with a No. camera 28 near the side of the placement table 26. 26 and is fixedly connected with a No. 1 fixed stand 31 at the upper end of the load-bearing base plate 1,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com