Annealing self-weight straightening method for P5 alloy steel continuous casting round billet

A technology for continuous casting of round billets and alloy steels, applied in the field of round billet steel straightening, can solve the problems of waste of energy consumption and increased cost, and achieve the effects of prolonging the soaking time, saving costs, and reducing the scrap amount of sawing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

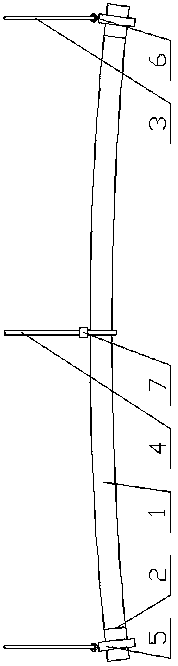

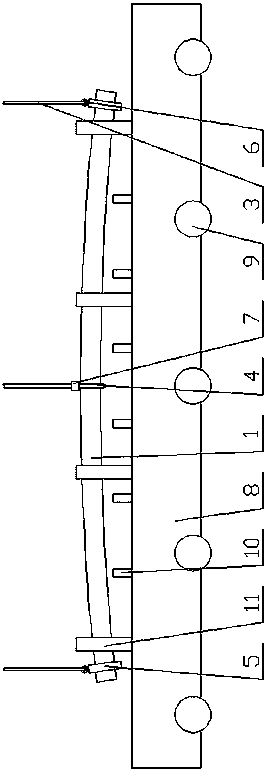

[0051] Such as Figure 5 Shown, a kind of diameter of the present invention is the method for P5 alloy steel continuous casting round slab annealing self-weight straightening of 500 millimeters, comprises the following steps:

[0052] 1) Take the two pad irons 10 symmetrically set on the trolley-type annealing furnace 8 with the central axis as the axis of symmetry as a group, measure the distance between each group of pad irons 10, and measure the distance between the two ends of the round billet 1 respectively. The symmetrical mark has a horn position marking circle 2, and the distance between the horn position marking rings 2 is equal to the distance between a group of symmetrical horns 10 on the trolley type annealing furnace 8, and the distance between the symmetrical horns 10 of the group is equal. The spacing between them is the set of symmetrical horns 10 which are smaller than the maximum spacing in the actual length of the round billet 1;

[0053] 2) Fork up the two...

Embodiment 2

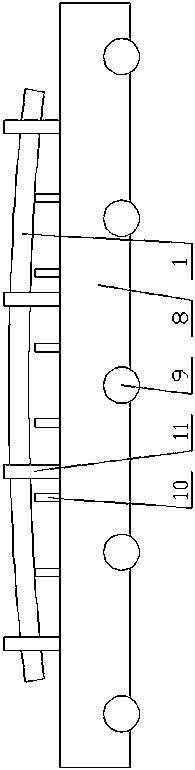

[0078] Such as Image 6 Shown, a kind of diameter of the present invention is the method for P5 alloy steel continuous casting round slab annealing self-weight straightening of 450 millimeters, except that the holding time of soaking is 30 hours, and the furnace temperature reduction speed of trolley type annealing furnace 8 is Except for 25° C. / hour, the rest of the process scheme is exactly the same as that of Example 1.

Embodiment 3

[0080] Such as Figure 7 Shown, a kind of diameter of the present invention is the method for P5 alloy steel continuous casting round slab annealing self-weight straightening of 380 millimeters, except that the holding time of soaking is 27 hours, and the furnace temperature reduction speed of trolley type annealing furnace 8 is Except for 32° C. / hour, the rest of the process scheme is exactly the same as that of Example 1.

[0081] The curvature of each round billet 1 in Examples 1 to 3 before annealing and the curvature after annealing, straightening and cooling were measured and calculated, and compared. get as Figure 8 The bending degree of the round billet shown (the bending degree of the continuous casting round billet is required to be ≤0.60%). Depend on Figure 8 It can be seen that the curvature of each round billet after annealing and straightening meets the requirements. And the straightening effect of the round billet with larger diameter is better.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com