Rapeseed screening and impurity removal device for production of rapeseed oil

A technology of rapeseed oil and rapeseed, which is applied in the direction of separating solids from solids with airflow, filtering, and solid separation. It can solve the problems of poor impurity removal effect and heavy workload, and achieve the improvement of impurity removal efficiency, Avoid excessive concentration of screening, good separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

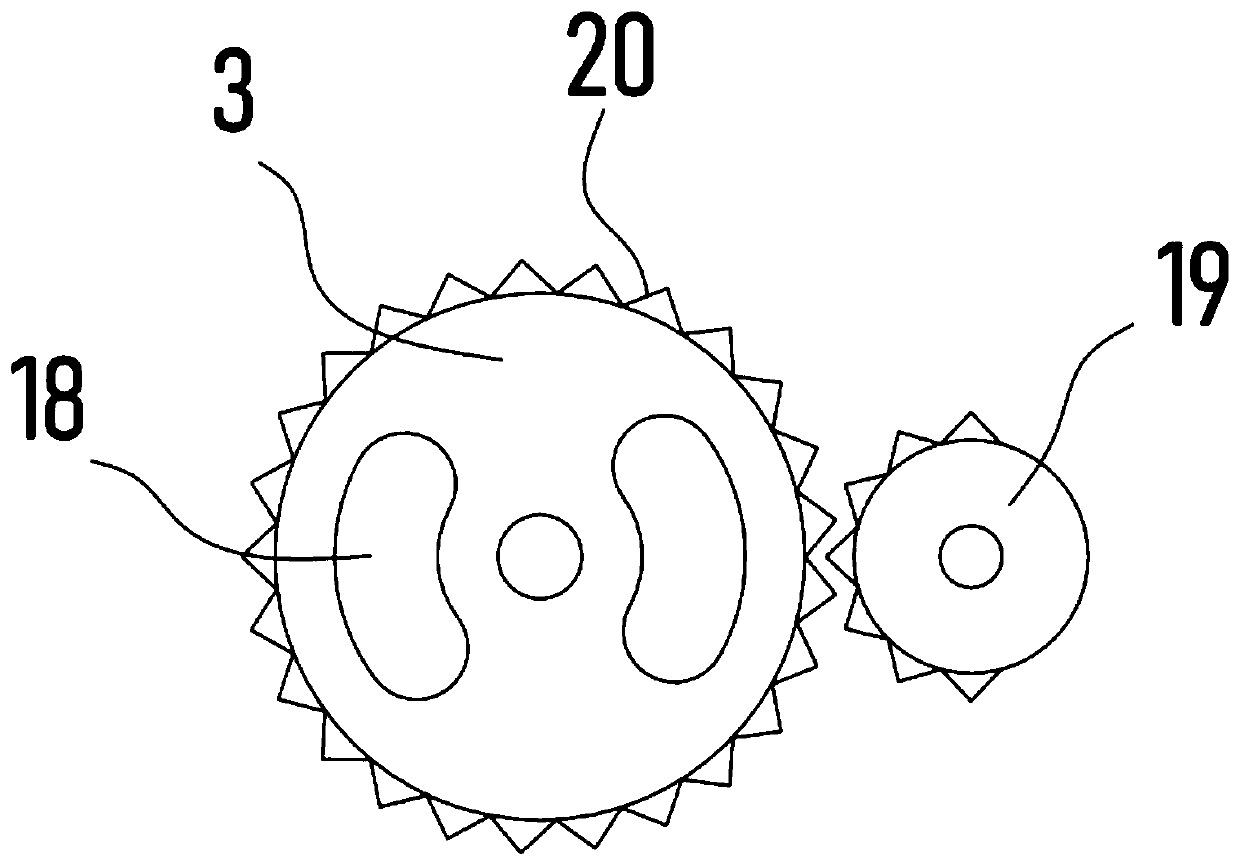

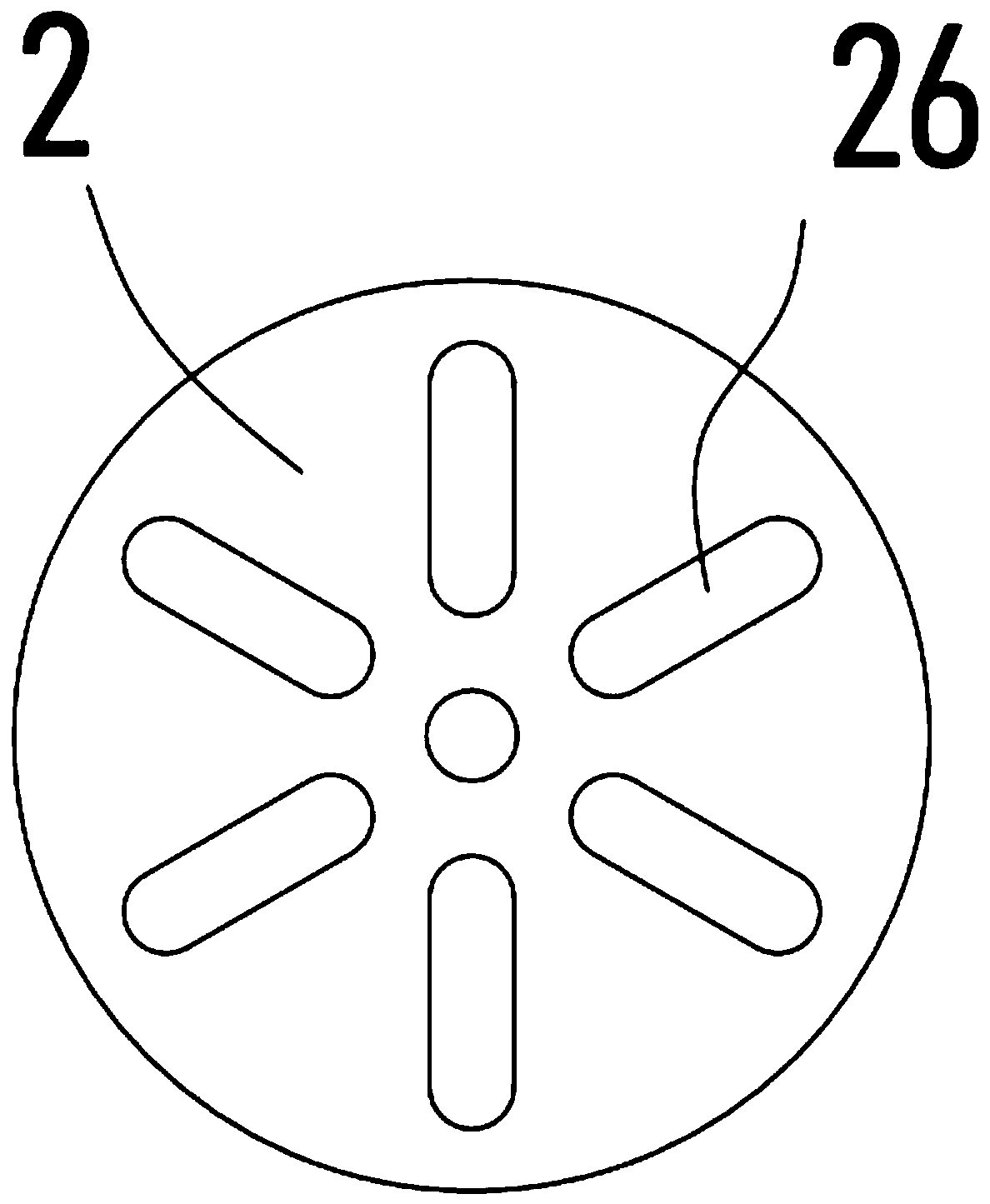

[0024] see Figure 1-6 , a rapeseed screening and impurity removal device for rapeseed oil production, comprising a support frame 1, a sieve groove 16 is hinged on the support frame 1, a sieve plate 13 is embedded in the bottom of the sieve groove 16, and a sieve plate 13 is installed above the sieve groove 16. There is a feeding bucket 2 fixed on the inner top of the support frame 1, and a feeding hopper 4 is connected and installed on the feeding bucket 2. Several scattered radial holes 26 are evenly opened on the bottom of the feeding bucket 2, and the side walls of the sieve groove 16 are fixed. There is a fixed frame 10, the bottom of the fixed frame 10 is fixed with a limit sleeve 21, a sliding column 23 is installed in the limit sleeve 21, and the lower end of the sliding column 23 is rotatably provided with a guide roller 24, and the support frame 1 is slidably installed with a guide roller 24 abutting wedge block 25, below the sieve trough 16 is provided with a collec...

Embodiment 2

[0030] In order to speed up the removal rate of impurities in rapeseed, on the basis of Embodiment 1, in addition, a drive motor 11 is fixed in the fixed frame 10, a pair of fan blades 9 are fixed on the output shaft of the drive motor 11, and the side wall of the sieve groove 16 is embedded. A screen plate 8 opposite to the fan blade 9 is provided, and a bellows 17 extending to the outside of the support frame 1 is embedded and installed on the side wall of the screen trough 16 opposite to the screen plate 8 .

[0031] When the sieve plate 13 sieves the rapeseed, the impurities stay in the sieve groove 16. At the same time, the driving motor 11 drives the fan blade 9 to rotate, and the fan blade 9 performs a horizontal blowing effect to the inside of the sieve groove 16. The specific gravity of impurities in the seeds is relatively light, and the airflow generated by the fan blades 9 blows the impurities away from the sieve groove 16, and the airflow carries the impurities int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com