Angle adjuster sheath gap oil injection device

A technology of oil injection device and angle adjuster, which is applied to the device and coating of the surface coating liquid, which can solve the problem of oil injection in the gaps of the sheath that does not apply angle adjuster, to achieve enhanced oil injection effect, oil saving, and accurate positioning Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

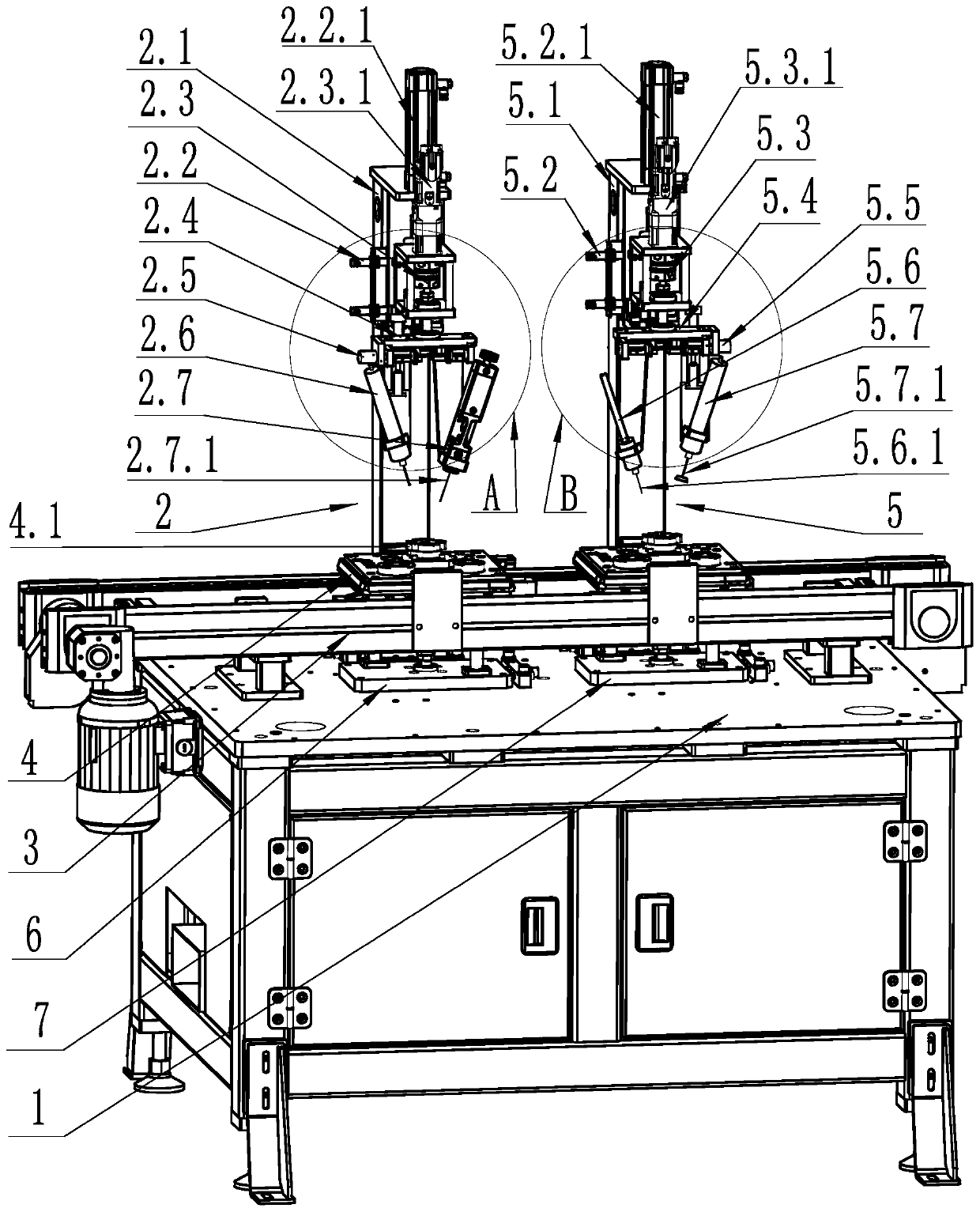

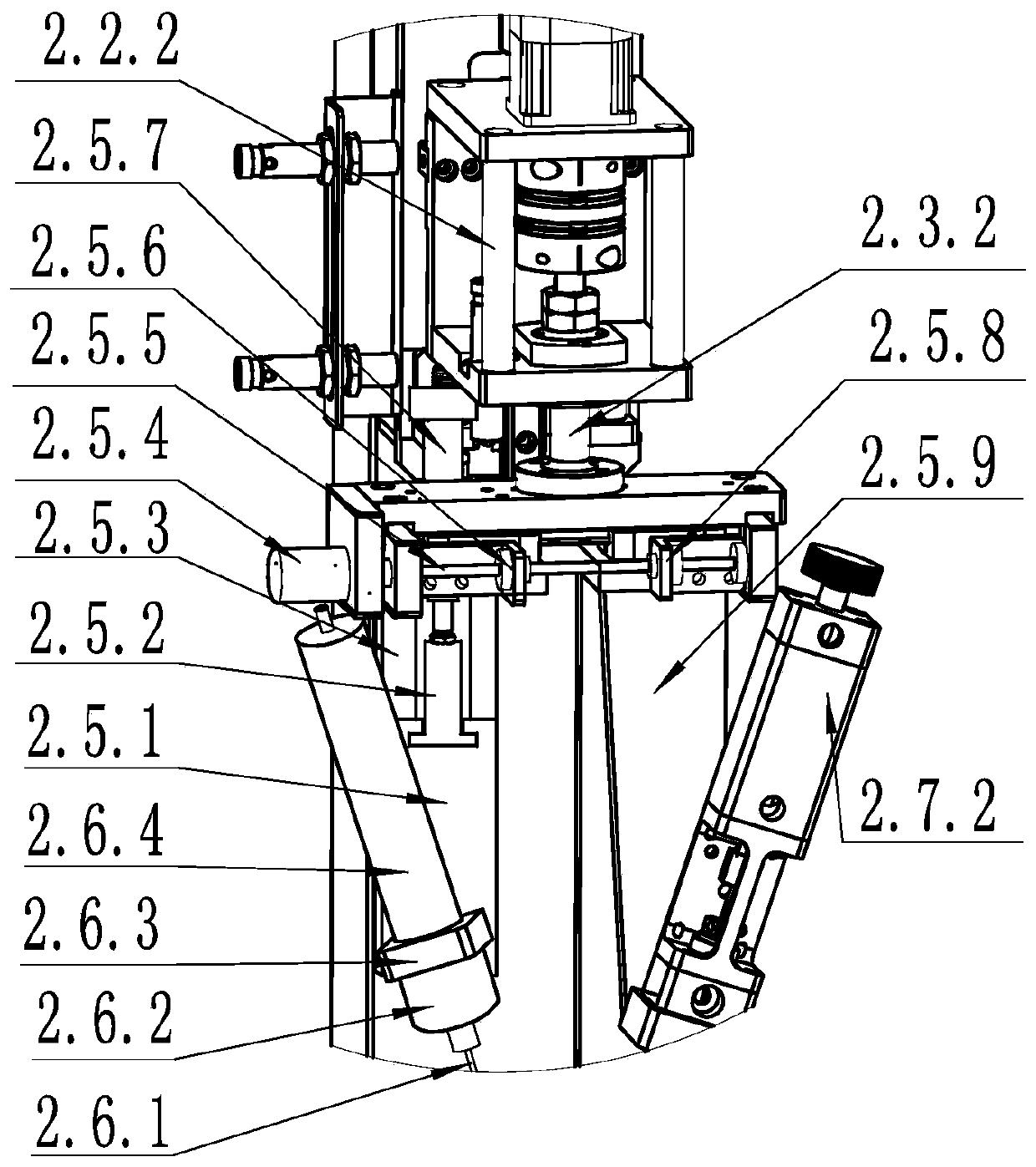

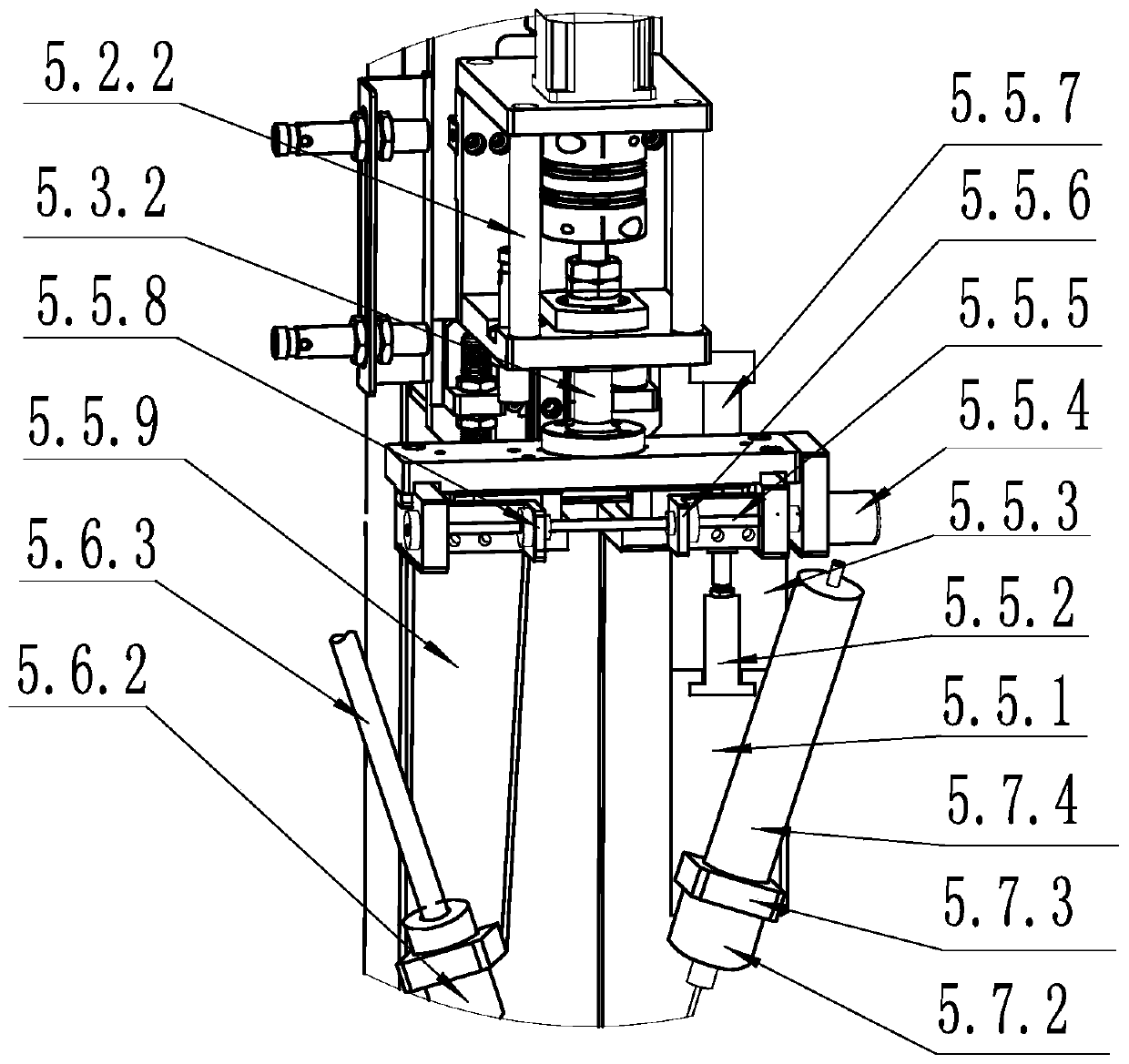

[0023] like figure 1 , figure 2 and image 3 As shown, an oil filling device for a recliner sheath gap includes a workbench 1 and a first station 2. The first station 2 includes a first column 2.1, a first lifting mechanism 2.2 and a first rotating mechanism 2.3. The said The first column 2.1 is fixed with the worktable 1, the first lifting mechanism 2.2 is fixed with the first column 2.1, the first rotating mechanism 2.3 is fixed with the first lifting mechanism 2.2; the first rotating mechanism 2.3 is provided with a first fixed seat 2.4, the first A fixed seat 2.4 is fixed with the first rotating mechanism 2.3. The first fixed seat 2.4 is provided with a vacuum oil pumping mechanism 2.6 and a quantitative oil filling mechanism 2.7. The vacuum oil pumping mechanism 2.6 includes an air suction nozzle 2.6.1. The vacuum generator 2.6.2, the first fixing block 2.6.3, the first waste oil collector 2.6.4, the air suction nozzle 2.6.1 are aligned with the oil filling gap 8.1 of ...

Embodiment 2

[0032] like figure 2 and image 3As shown, on the basis of Embodiment 1, the first fixing base 2.4 is provided with a first adjusting mechanism 2.5, the quantitative oil filling mechanism 2.7 is fixed with the first fixing base 2.4 through the first adjusting mechanism 2.5, and the vacuum filling mechanism 2.6 The first adjustment mechanism 2.5 is fixed with the first fixed seat 2.4. The first adjustment mechanism 2.5 includes a first vertical sliding block 2.5.1, a first adapter block 2.5.2, a first horizontal sliding seat 2.5.3, a second Motor 2.5.4, first screw pair 2.5.5, first nut fixing block 2.5.6, second cylinder 2.5.7, second nut fixing block 2.5.8, second horizontal sliding seat 2.5.9, first vertical The sliding block 2.5.1 is slidably connected with the first horizontal sliding seat 2.5.3 through the first linear guide rail pair, the second air cylinder 2.5.7 is fixed on the first horizontal sliding seat 2.5.3, and the second air cylinder 2.5.7 piston rod It is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com