A kind of preparation method of modified polyvinylidene fluoride film

A polyvinylidene fluoride membrane and modification technology, applied in the field of membrane separation, can solve the problems of low pressure resistance and membrane strength, poor comprehensive performance, poor membrane uniformity, etc., to improve pressure resistance and tightness. Strength issues, the effect of improving hydrophilicity and stain resistance, and good mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Add 1g of tetrabutyl titanate and 3g of glacial acetic acid to 10g of N-methylpyrrolidone solvent, stir evenly to obtain uniform and transparent TiO 2 Nanoparticle sol, spare;

[0033] Add 1g of PVA and 3g of lithium chloride to 70g of dimethylacetamide solvent, stir at 80°C for 4h until the system is evenly mixed, then add 2g of polyvinylpyrrolidone and 10g of PVDF, continue stirring at 80°C for 3h until the system is evenly mixed; Add the TiO 2 Nanoparticle sol, continue to stir at 80°C for 2 hours until the system is evenly mixed, and a uniform casting solution is obtained;

[0034] Stop the reaction, filter, stand for heat preservation and defoaming for 12 hours, cool until the temperature of the casting solution drops to 25°C, and evenly coat the cooled casting solution on the polyester non-woven fabric at a rate of 12m / min, and use a scraper The film was scraped evenly with a film knife to form a film, and the modified polyvinylidene fluoride film was obtained a...

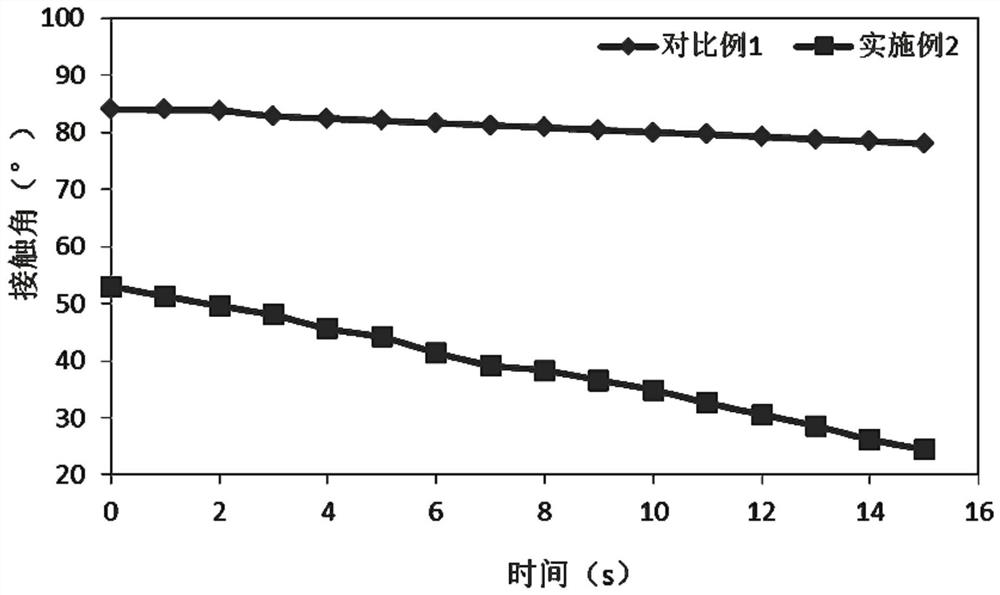

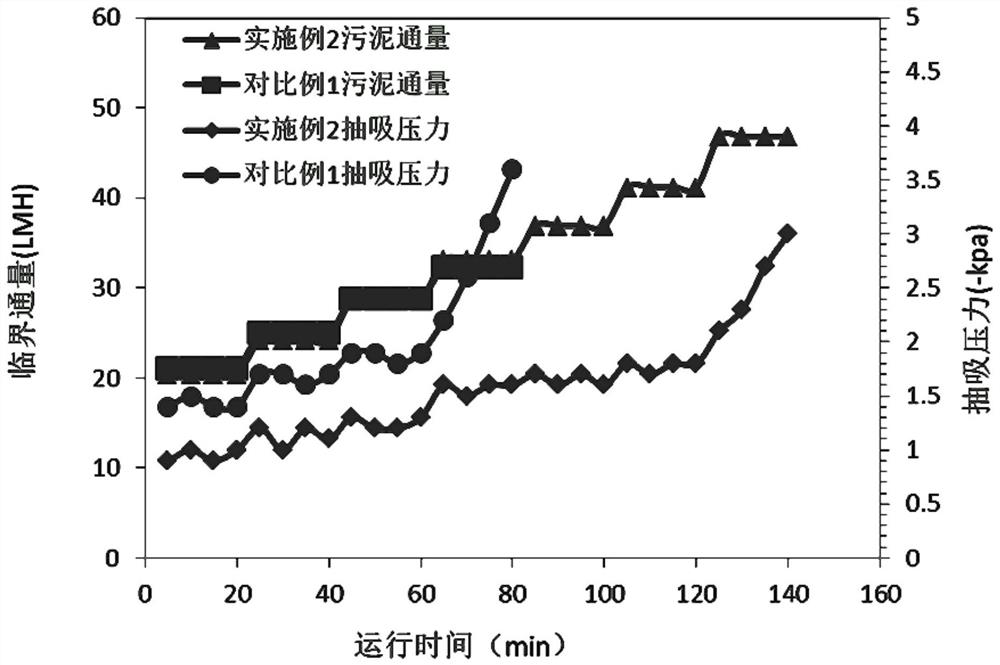

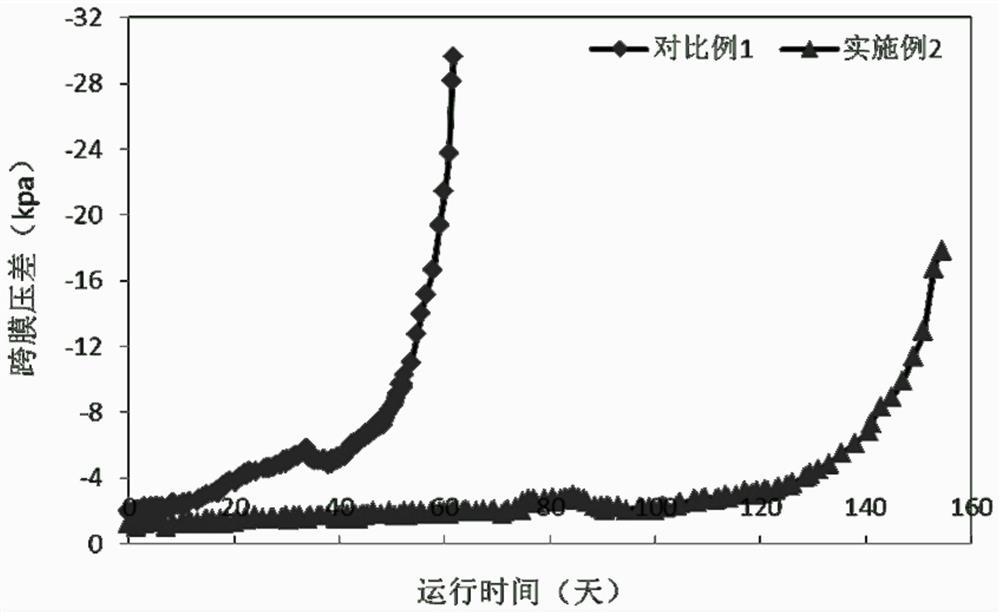

Embodiment 2

[0036] Add 2g of tetrabutyl titanate and 4g of dodecylbenzenesulfonic acid to 10g of N-methylpyrrolidone solvent, and stir evenly to obtain uniform and transparent TiO 2 Nanoparticle sol, spare;

[0037] Add 2g of PVA and 2g of lithium chloride to 68g of dimethylacetamide solvent, stir at 85°C for 4h until the system is evenly mixed, then add 3g of polyethylene glycol and 9g of PVDF, continue stirring at 85°C for 3h until the system is evenly mixed; Add the TiO 2 Nanoparticle sol, continue to stir at 85°C for 2 hours until the system is evenly mixed, and a uniform casting solution is obtained;

[0038] Stop the reaction, filter, stand for heat preservation and defoaming for 12 hours, cool until the temperature of the casting solution drops to 25°C, apply the cooled casting solution evenly on the polyester non-woven fabric at a rate of 9m / min, and use a scraper The film was scraped evenly with a film knife to form a film, and the modified polyvinylidene fluoride film was obta...

Embodiment 3

[0040] Add 2.5g of tetrabutyl titanate and 6g of dodecylbenzenesulfonic acid to 10g of dimethylacetamide solvent, and stir evenly to obtain uniform and transparent TiO2 Nanoparticle sol, spare;

[0041] Add 1.5g of PVA and 2.5g of lithium chloride to 66.5g of dimethylacetamide solvent and stir at 85°C for 4h until the system is evenly mixed, then add 2g of polyvinylpyrrolidone and 9g of PVDF, and continue stirring at 85°C for 3h until the system is evenly mixed ; Then add the TiO 2 Nanoparticle sol, continue to stir at 85°C for 2 hours until the system is evenly mixed, and a uniform casting solution is obtained;

[0042] Stop the reaction, filter, stand for heat preservation and defoaming for 12 hours, cool until the temperature of the casting solution drops to 25°C, apply the cooled casting solution evenly on the polyester non-woven fabric at a rate of 9m / min, and use a scraper The film was scraped evenly with a film knife to form a film, and the modified polyvinylidene fluo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com