Rapid baking method and device for cooked puff cake

A technology for rapid baking and cooked flour, applied in baking methods, baking, baking hollow foods and other directions, can solve the problems of increasing product preservation and transportation costs, affecting the yield and taste of finished products, and high energy consumption and time costs. Improve poor formability, good appearance and shape, slow down the effect of rapid escape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

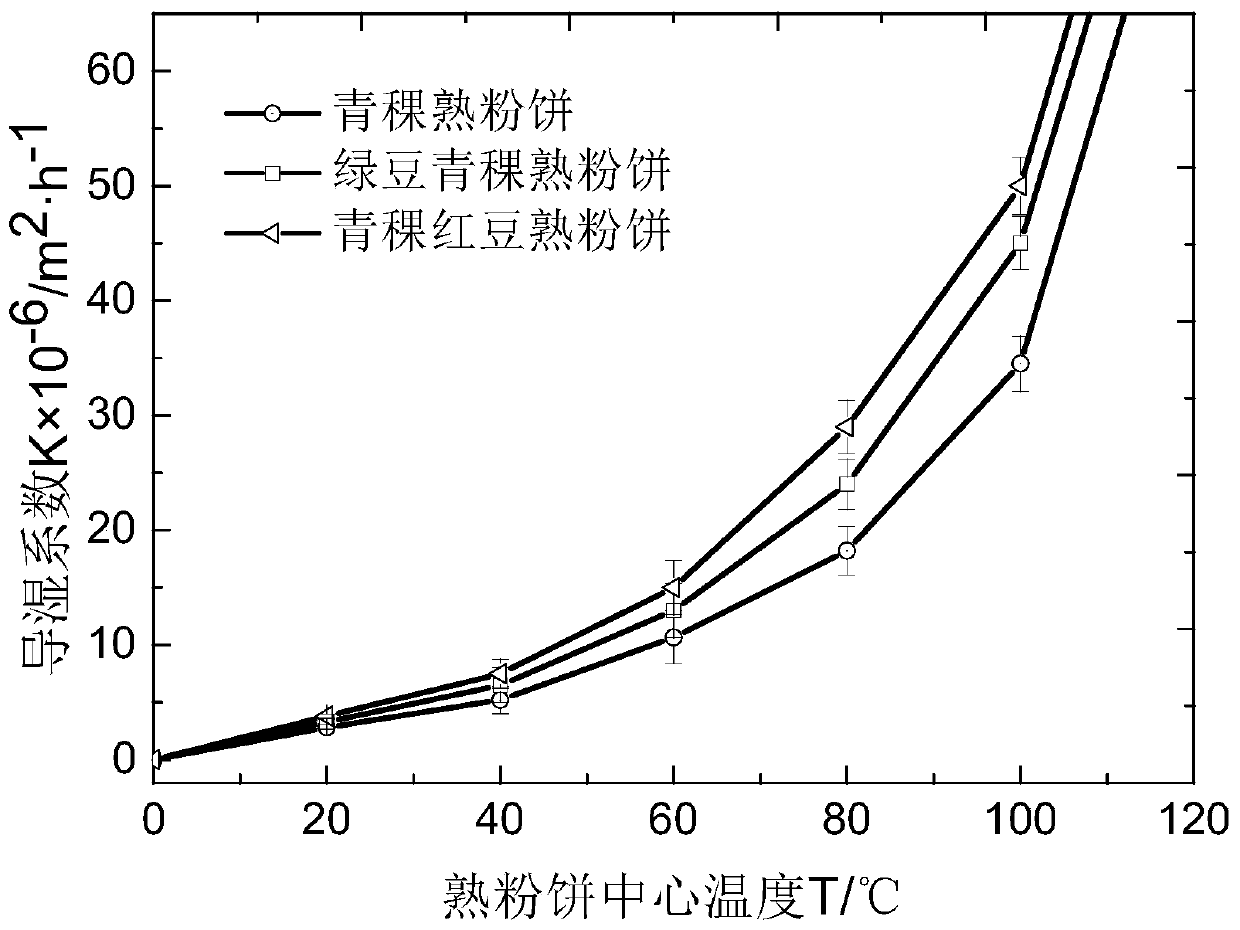

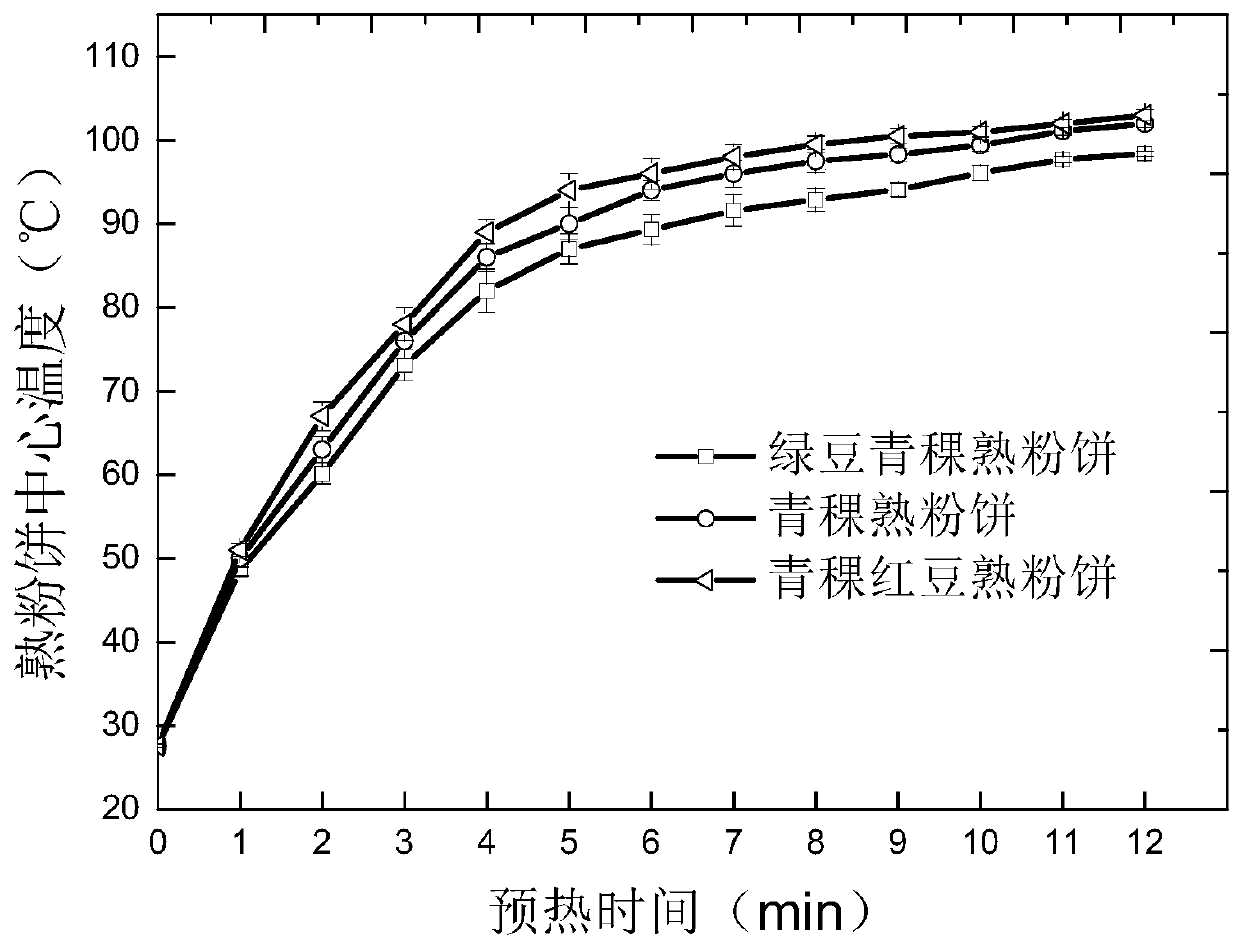

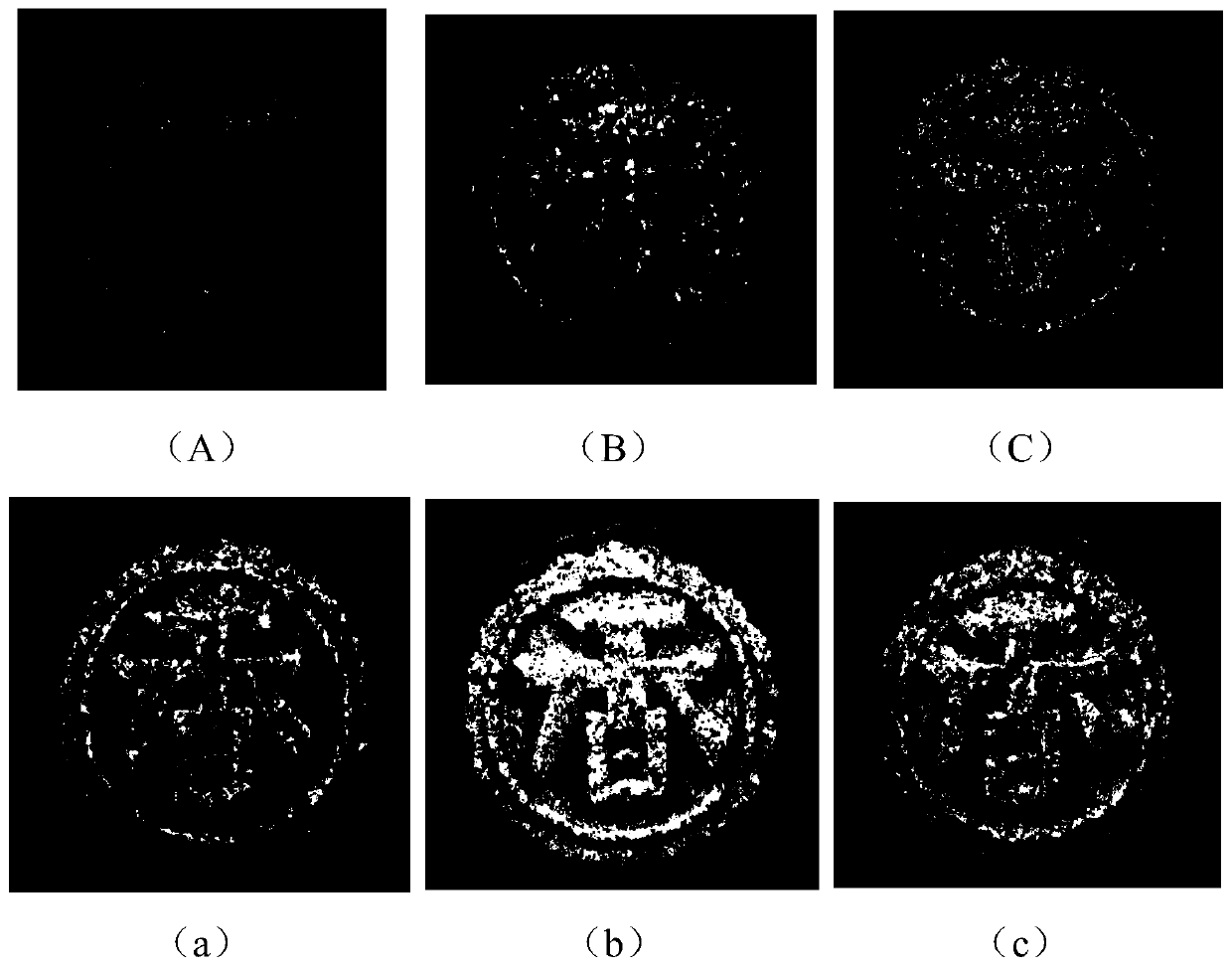

Embodiment 1

[0045] A rapid baking equipment for cooked powder cakes, which includes an equal-humidity preheating component, a hot-air baking component, a central processing unit, and a display; The hot air baking components are connected and baked by controlling the two, the central processing unit is electrically connected with the display, and the display is used to display the production control status and situation.

[0046] Isohumid preheating components include isohumid preheating body, front-end conveying mechanism, water storage tank, water pump, conveying pipeline, ultrasonic nebulizer, multi-component shunt mechanism, front-end electric heating mechanism, front-end temperature sensor, humidity sensor, front-end electric motor. The isohumid preheating body is supported on a plane by columns. The front-end conveying mechanism runs through the interior of the iso-humid preheating body; the front-end conveying mechanism is used to place and convey the prefabricated cooked powder ca...

Embodiment 2

[0058] In this embodiment, a kind of quick-baking equipment for cooked powdered cakes is used to make mung bean and highland barley cooked powdered cakes. The device used is the same as in Example 1, and the specific conditions of the production method are slightly different, including the following steps:

[0059] (1) Take 70g of cooked mung bean powder and 30g of cooked highland barley powder, mix the two, and stir to obtain the mixed powder for later use; wherein, the particle size of the cooked mung bean powder is 100 mesh, and the particle size of the cooked highland barley powder is 80 mesh.

[0060] (2) Get 55g of powdered sugar, 8g of water, and 15g of rapeseed oil, mix the three, and stir to obtain a pasty mixture for later use.

[0061] (3) Add the mixed powder of step (1) to the pasty mixture prepared in step (2), and obtain a shaped cooked powder cake through stirring and compression molding.

[0062] (4) Put the cooked vermicelli in step (3) into a kind of rapid b...

Embodiment 3

[0067]In this embodiment, a kind of quick-baking equipment for cooked powder cake is used to make red bean and highland barley cooked powder cake. The device used is the same as that of Embodiment 1, and the specific conditions of the production method are slightly different, including the following steps:

[0068] (1) Get 60g of cooked highland barley powder and 40g of cooked red bean powder, mix the two, and stir to obtain the mixed powder for later use; wherein, the particle size of the cooked red bean powder is 100 mesh, and the particle size of the cooked highland barley powder is 100 mesh.

[0069] (2) Take 60g of powdered sugar, 9g of water, and 18g of peanut oil, mix the three, and stir to obtain a pasty mixture for subsequent use;

[0070] (3) Add the mixed powder of step (1) to the paste mixture prepared in step (2), and obtain the cooked powder cake of molding through stirring and compression molding;

[0071] (4) Put the cooked vermicelli in step (3) into a kind of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com