Film-drawing extruder die head with high safety

A safe and extruder technology, applied in the field of dies on film stretching extruders, can solve problems affecting production efficiency, waste of raw materials, PET melt leakage, etc., to prolong the cycle of cleaning dies and increase the ambient temperature and humidity, reducing the effect of the chance of occurrence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

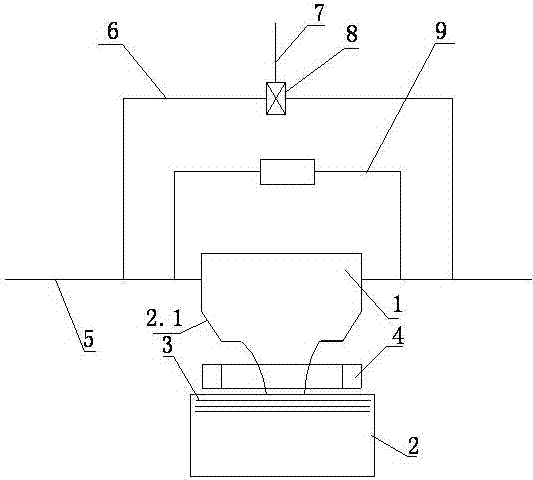

[0013] see figure 1 , the present invention relates to a die head of a stretched film extruder with high safety, including a die head 1, the lower part of the die head 1 is connected with a chilling drum 2 through a pipeline, and an anti- Electrostatic wire 3, the bottom side wall of the die head 1 is a side seal 2.1, and a collection device 4 is provided directly below the side seal 2.1. The collection device 4 is used to collect PET melt leaked from a side seal 2.1. The collection device 4 can be a collection tank or a baffle or a paper head. The die head 1 is connected to the melt pipe 5 used for film drawing production. A steam pipe 6 is connected to the front and rear ends of the die head 1. The steam pipe 6 6 is connected to the steam inlet pipe 7, and a valve 8 is arranged at the connection between the steam inlet pipe 7 and the steam pipe 6, and a humidifier 9 is fixed on the periphery of the die head 1, and the steam pipe 6 and the humidifier 9 can be increased Ambie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com