Battery cathode material precursor, battery cathode material as well as preparation method and application of battery cathode material precursor

A battery cathode and precursor technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of electrochemical performance impact, complex modification process, few material doping modification, etc. simple method effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] As an aspect of the technical solution of the present invention, what it relates to is a kind of preparation method of the positive material precursor of battery, comprising:

[0037] Dissolving Ni-based nitrate, Co-based nitrate, Mn-based nitrate and Cd-based nitrate in absolute ethanol to obtain a mixed solution;

[0038] The mixed solution is subjected to solvothermal reaction to co-precipitate Ni, Co, Mn and Cd elements, and the obtained precipitate is post-treated to obtain a Ni-Co-Mn-Cd-based battery positive electrode material precursor.

[0039] The present invention performs in-situ doping modification on the material during the synthesis stage of the battery positive electrode material precursor, and the specific reaction principle is shown in the following equation:

[0040] 7CH 3 CH 2 OH+4NO 3 - →7CH 3 CHO+2NO↑+N 2 O+4OH - +5H 2 O; (1)

[0041] 3Ni 2+ +6OH - +2H 2 O→3Ni(OH) 2 2H 2 O↓; (2)

[0042] 2Co 2+ +Mn 2+ +6OH - →MnCo 2 o 4 ↓+3H 2 ...

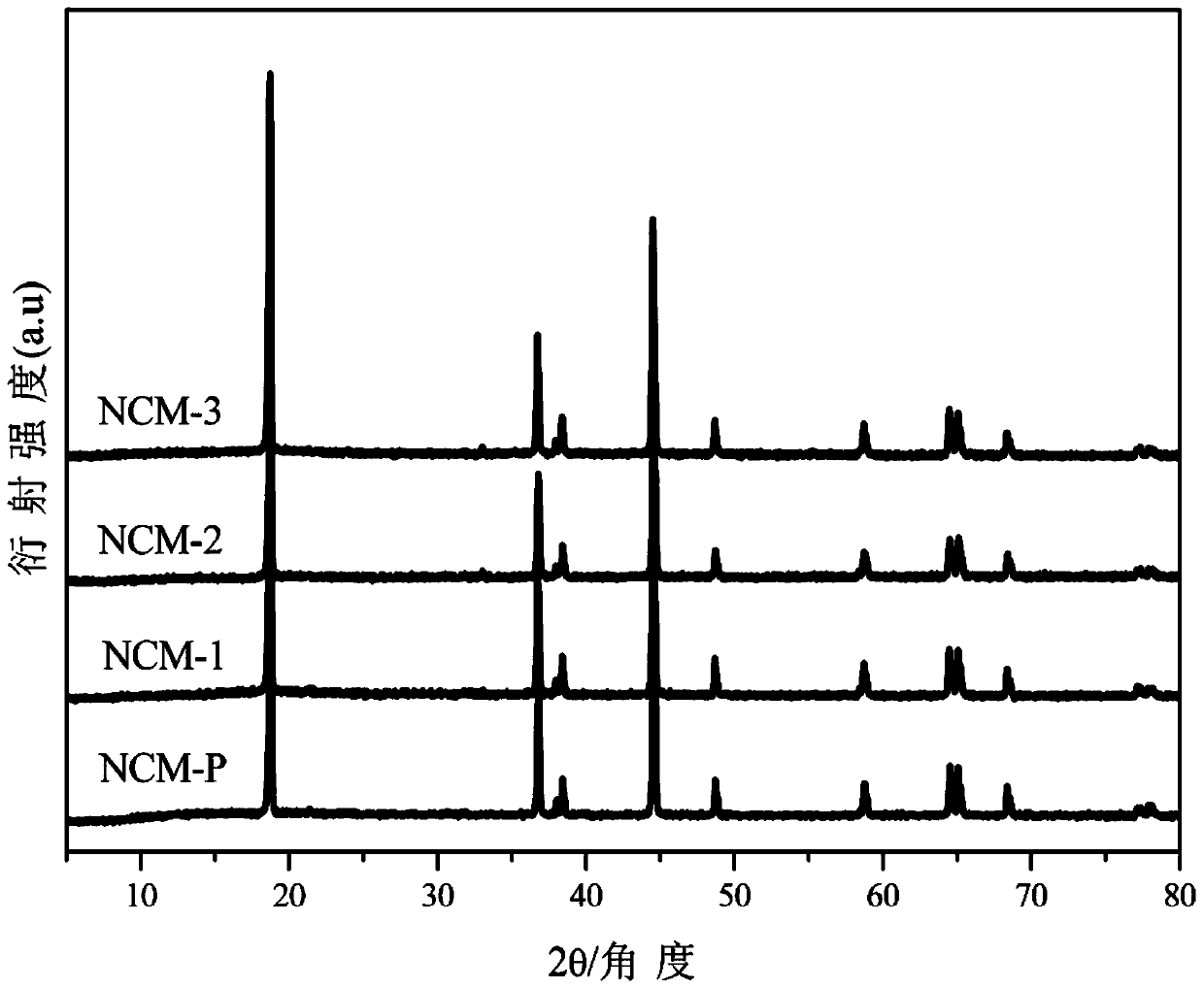

Embodiment 1

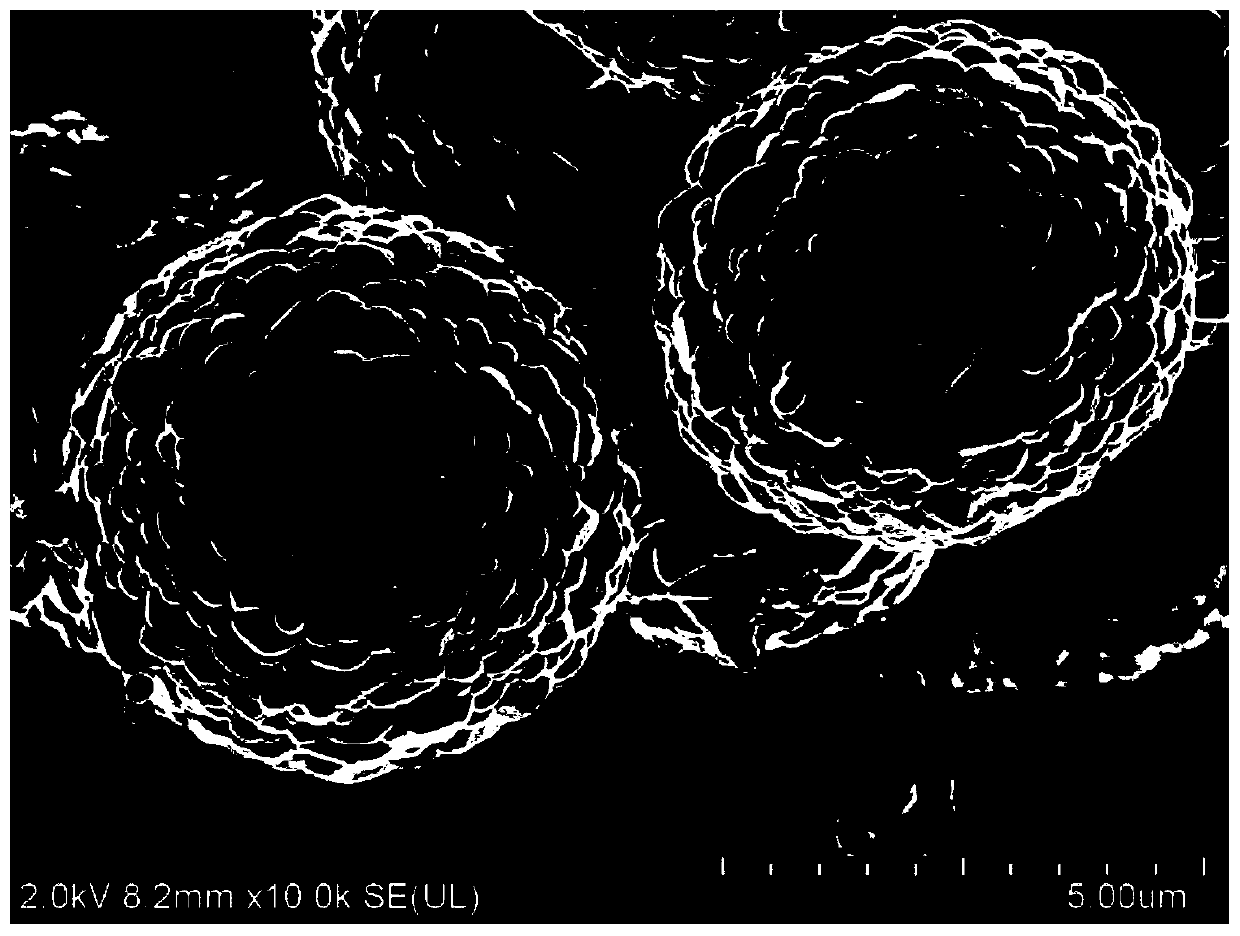

[0071] The preparation and test method of lithium-ion battery positive electrode material precursor, battery positive electrode material (NCM-1), lithium-ion battery doped with 0.01mol Cd include the following:

[0072] (1) 34.545852g Ni(NO 3 ) 2 ·6H 2 O, 11.524788g Co(NO 3 ) 2 ·6H 2 O, 14.17284g Mn(NO 3 ) 2 (50wt% aqueous solution) and 0.61692g of Cd(NO 3 ) 2 4H 2 O was dissolved in 150ml of absolute ethanol, and the mixed solution was stirred at room temperature until it was completely dissolved, and then the solution was divided into three parts and moved to three 100mL polytetrafluoroethylene reactors; the reactors were moved into an oven at 150 Place it at ℃ for 12 hours; finally wash the precipitate 4 to 5 times with absolute ethanol, and then dry the precipitate in an oven at 80 ℃ for 12 hours. In order to make it have a good shape after high-temperature roasting, the First roast at 450°C for 5 hours in the furnace to obtain a 622 battery cathode material prec...

Embodiment 2

[0081] The preparation and test method of lithium-ion battery cathode material precursor, battery cathode material (NCM-2), lithium-ion battery doped with 0.02mol Cd include the following:

[0082] (1) 34.197g Ni(NO 3 ) 2 ·6H 2 O, 11.408g Co(NO 3 ) 2 ·6H 2 O, 14.0296g Mn(NO3 ) 2 (50wt% aqueous solution) and 1.234g of Cd(NO 3 ) 2 4H 2 O was dissolved in 100ml of absolute ethanol, and the mixed solution was stirred at room temperature until it was completely dissolved, and then the solution was divided into three parts and moved to three 100mL polytetrafluoroethylene reactors; the reactors were moved into an oven at 150 Place it at ℃ for 10h; Finally, wash the precipitate with absolute ethanol 4 to 5 times, and then dry the precipitate in an oven at 70°C for 14h. In order to make it have a good shape after high-temperature roasting, the First roast at 440°C for 6 hours in the furnace to obtain a 622 battery cathode material precursor with a doping amount of 0.02mol Cd; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| retention rate | aaaaa | aaaaa |

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com