Simulation test platform and simulation test method of transformer fire propagation behavior

A technology of simulation test and transformer, which is applied in the direction of using combustion for chemical analysis, etc., can solve the problems of short service life, fire spread test cannot be repeated many times, and the power of heating device is large, so as to achieve the effect of reducing test cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

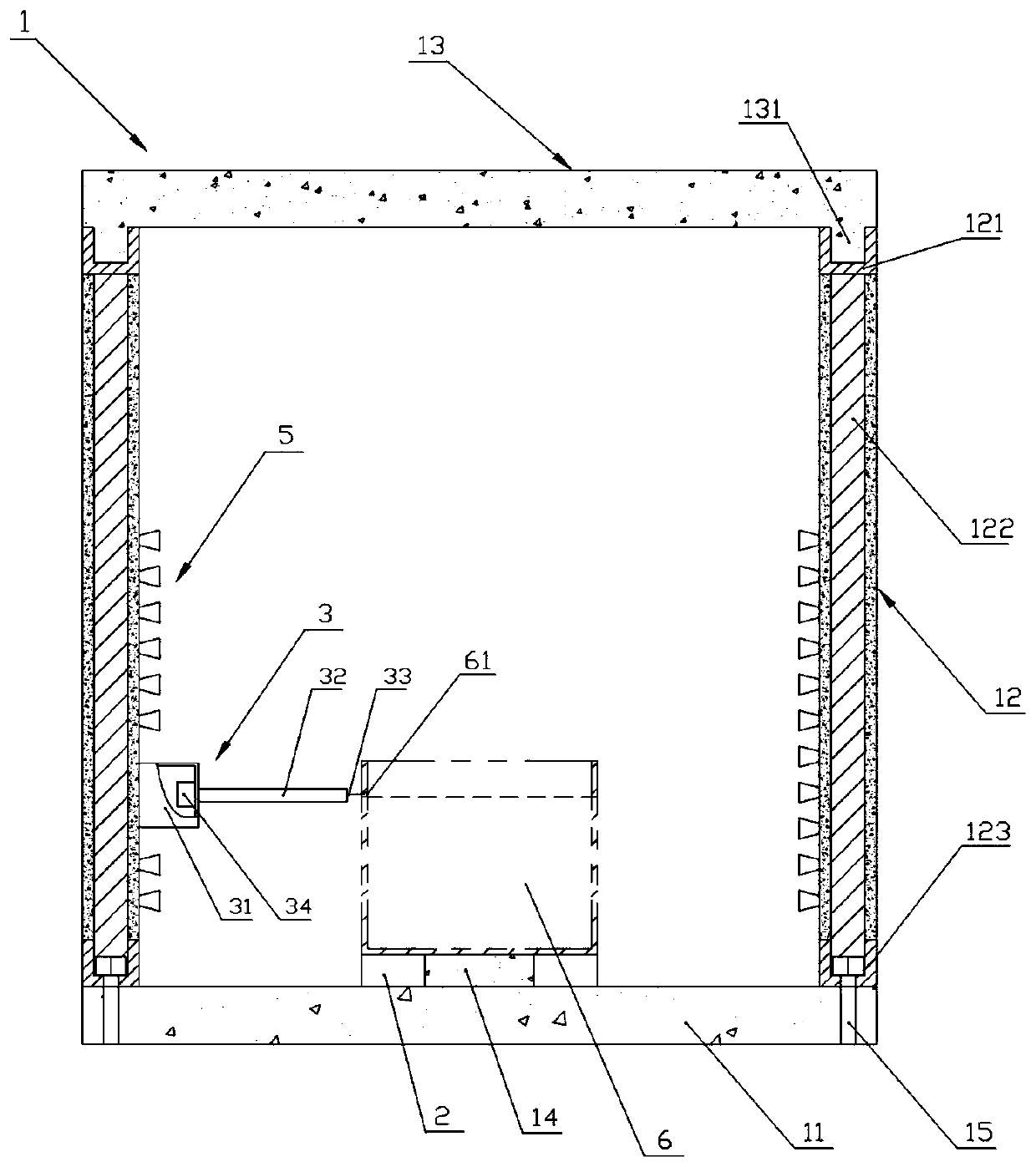

[0042] Such as figure 1 As shown, the simulation test platform for the fire spread behavior of the transformer provided in this embodiment includes an explosion-proof isolation room 1 , a heating device 2 , an ignition device 3 , a data acquisition system 4 and a fire extinguishing device 5 .

[0043] Such as figure 2 , image 3 As shown, the explosion-proof isolation room 1 includes a bottom plate 11, a partition wall 12 and a top cover 13. The bottom plate 11 is provided with a boss 14, and each wall is an explosion-proof reinforced concrete wall, the anti-riot load ≥ 850Kpa, and the fire resistance limit ≥ 4 hours. Wherein the separation wall 12 comprises a top keel 121, a bottom keel 122 and a structural keel 123 connected between the two, the separation wall 12 is reserved with an observation hole 124 when pouring concrete so as to place various monitors of the data acquisition system 4, And be provided with tempered glass 125 in order to prevent monitor from being dam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com