Concrete pouring process for multi-layer beam slab outer eave structure

A technology for concrete and concrete strength, which is applied in the direction of tools, buildings, and building structures for roof engineering, can solve problems such as concrete sub-strength pouring, and achieve the effect of improving construction progress, ensuring overall stability, and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings.

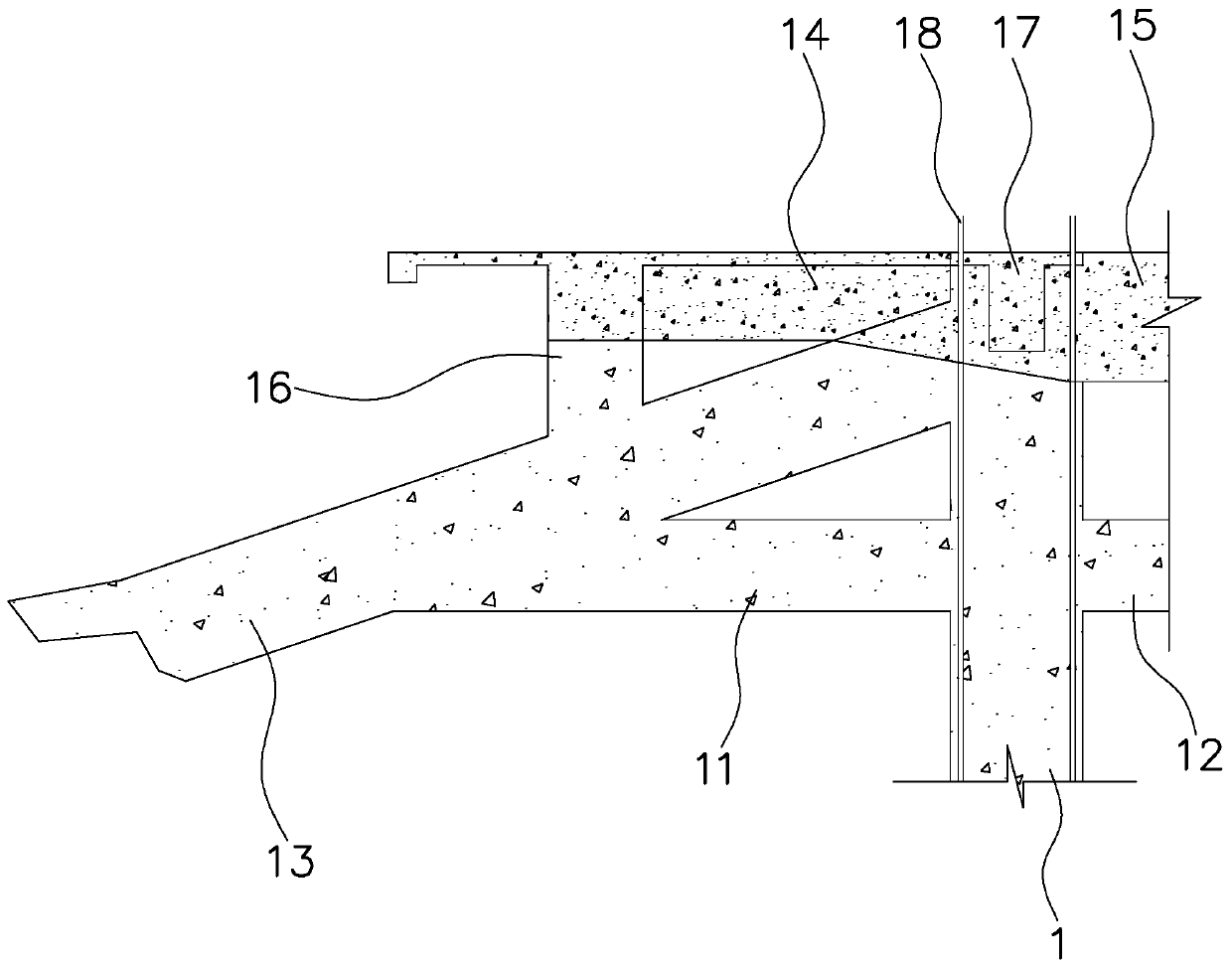

[0034] refer to figure 1 , is a multi-layer girder slab outer eaves structure disclosed by the present invention, comprising a vertical support column 1, on both sides of the support column 1 are respectively fixed horizontally arranged flat joists 11 and flat joist inner beams 12. Wherein the flat joist 11 extends outward.

[0035] refer to figure 1 , a wing angle beam 13 located above the flat joist 11 is fixed on the support column 1 . In this embodiment, the wing angle beam 13 extends obliquely downward on the side facing away from the supporting column 1 , and overlaps the flat joist 11 . Between the wing corner beam 13 and the flat joist beam 11, a connecting beam for connection is provided.

[0036] refer to figure 1 A flat beam 14 and an inner flat beam 15 above the corner beam 13 are fixed horizontally on both sides of the support column 1, wher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com