Liner pipe arrangement type heat-conducting superconductor polishing roller

A technology of ironing rollers and superconductors, which is applied to textiles, papermaking, and fabric surface trimming. It can solve the problems of affecting the quality of ironing, uneven temperature on the surface of the roller body, and low conduction efficiency, so as to improve the quality of ironing and heat transfer. The effect of fast speed and high thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

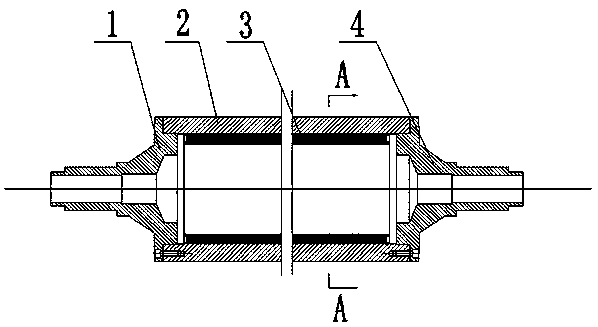

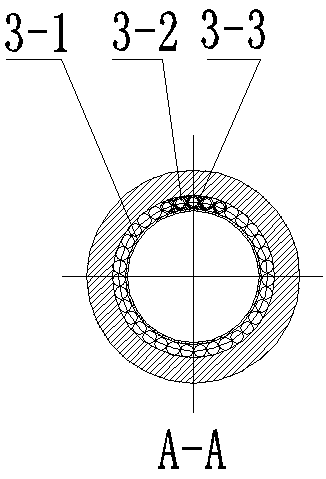

[0016] Such as figure 1 and figure 2 As shown, a liner tube-type heat-conducting superconductor ironing roller includes a left shaft head 1, a ironing roller shell 2, a liner liner heat-conducting superconductor device 3 and a right shaft head 4; the ironing roll shell One end of 2 is provided with a left shaft head 1, and the other end of the ironing roller shell 2 is provided with a right shaft head 4, and the ironing roller shell 2 is fixedly connected with the left shaft head 1 and the right shaft head 2 to form the main body of the ironing roller; The ironing roller shell 2 is provided with a liner tube heat-conducting superconductor device 3, and the liner tube heat-conducting superconductor device 3 includes a liner steel pipe 3-1, several steel pipe bodies 3-2 encapsulating the heat-conducting superconductor and upper and lower two. A group of aluminum profiles 3-3; several steel pipe bodies 3-2 encapsulating heat-conducting superconductors are arranged on the outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com