Oil heated ironing roller

A technology of ironing rollers and oil heating, which is applied in textiles, papermaking, and fabric surface trimming, etc. It can solve the problems of affecting product quality, large temperature difference between the two ends of the ironing roller, and high energy consumption, so as to save high power consumption and temperature conduction The effect of balanced and reasonable conduction structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

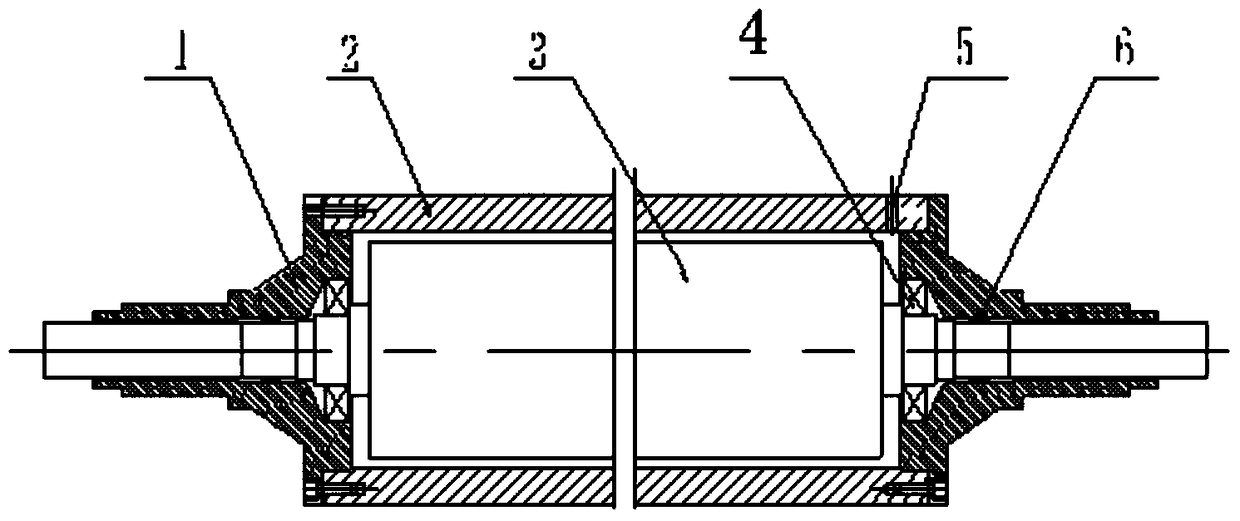

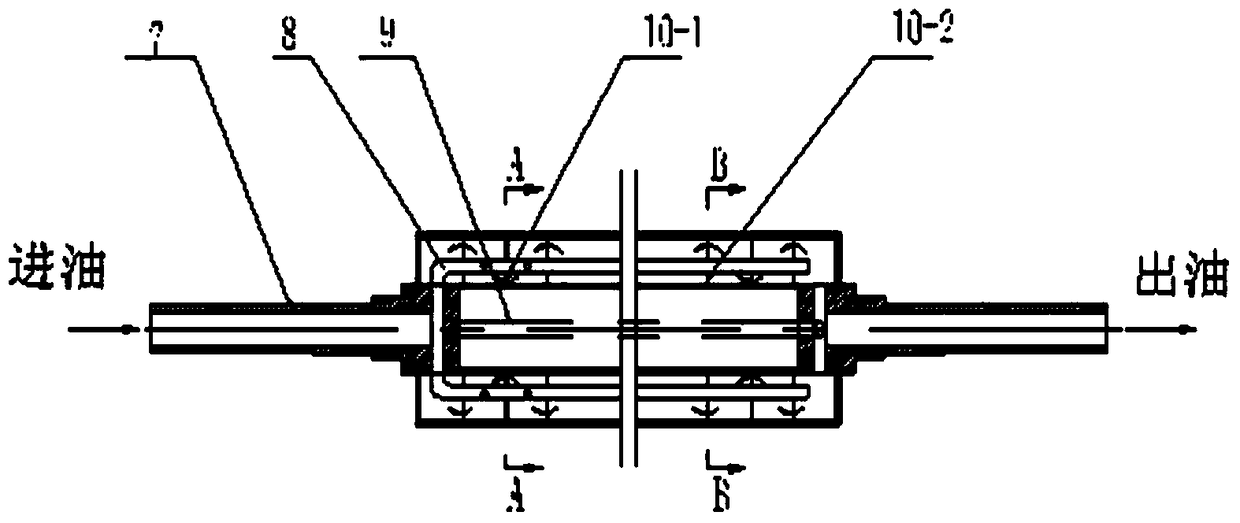

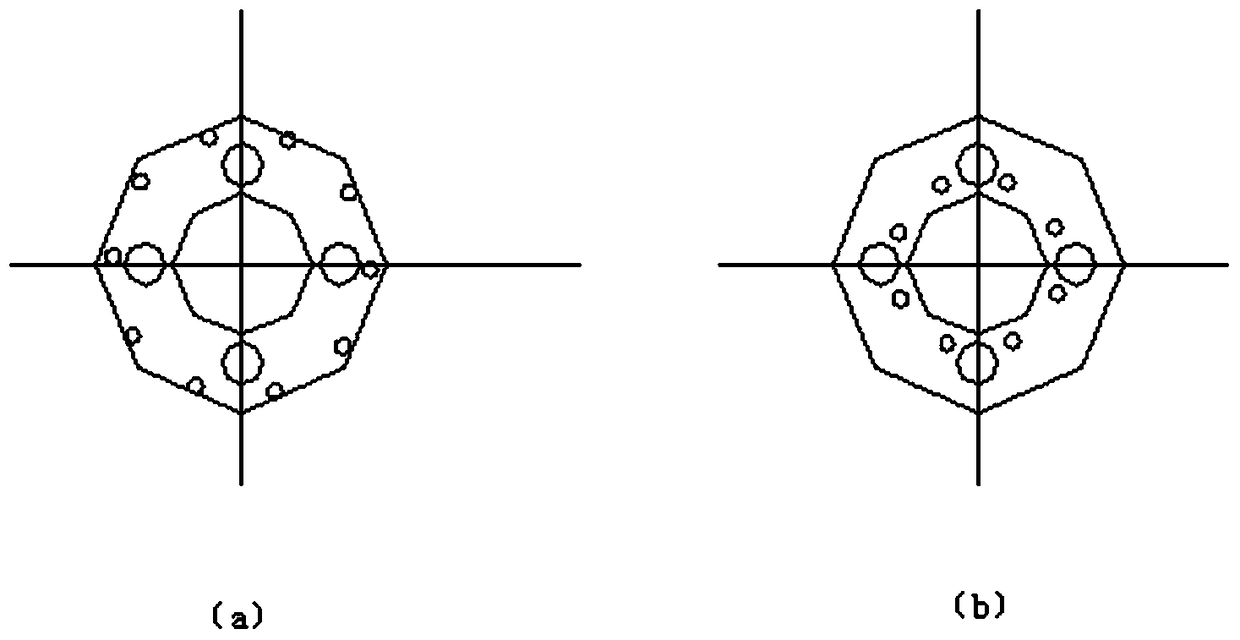

[0018] An oil-heated ironing roller, including a shaft head 1, a ironing roller shell 2, a heat transfer oil liner 3, a bearing 4, and a skeleton oil seal 6; The oil liner 3 passes through the ironing roller shell 2 and the shaft head 1 at both ends and rotates with the ironing roller shell 2 and the shaft head 1. The shaft end on the two ends of the heat transfer oil liner 3 and the shaft head 1 hole Bearings 4 and skeleton oil seals 6 are arranged in sequence between them; on the side wall of the ironing roller shell 2, there is an oil filling hole 5 communicating with the gap between the ironing roller shell 2 and the heat transfer oil liner 3, and the heat transfer oil liner 3 Between the two inner shaft ends is the main shaft 7, the main shaft 7 is covered with a splitter plate perpendicular to the main shaft, and the splitter holes on the adjacent splitter plates are sequentially distributed on the inner or outer ring edges of the splitter plate, characterized in that: T...

Embodiment 2

[0022] An oil-heated ironing roller, including a shaft head 1, a ironing roller shell 2, a heat transfer oil liner 3, a bearing 4, and a skeleton oil seal 6; The oil liner 3 passes through the ironing roller shell 2 and the shaft head 1 at both ends and rotates with the ironing roller shell 2 and the shaft head 1. The shaft end on the two ends of the heat transfer oil liner 3 and the shaft head 1 hole Bearings 4 and skeleton oil seals 6 are arranged in sequence between them; on the side wall of the ironing roller shell 2, there is an oil filling hole 5 communicating with the gap between the ironing roller shell 2 and the heat transfer oil liner 3, and the heat transfer oil liner 3 Between the two inner shaft ends is the main shaft 7, the main shaft 7 is covered with a splitter plate perpendicular to the main shaft, and the splitter holes on the adjacent splitter plates are sequentially distributed on the inner or outer ring edges of the splitter plate, characterized in that: T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com