Styrene-maleic anhydride copolymer/carbon nanotube non-woven fabric and preparation method thereof

A technology of acidifying carbon nanotubes and carbon nanotubes, which is applied in the direction of single-component synthetic polymer rayon, non-woven fabrics, filament/thread forming, etc., can solve the problems of poor mechanical properties and weak anti-fouling properties, and achieve Enhanced mechanical strength, extended service life, and low raw material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

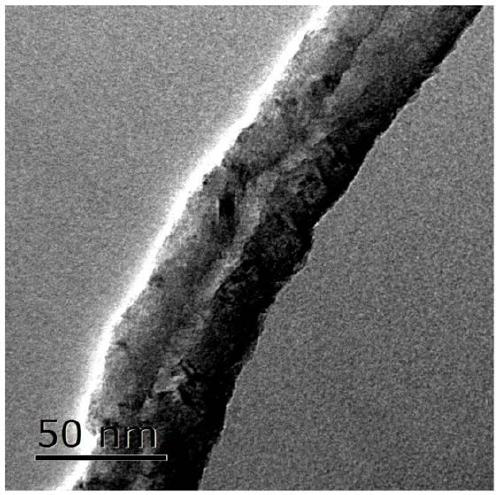

[0028] The invention discloses an oil-water separation non-woven membrane material, which is made by grafting and coating carbon nanotubes after acidification treatment by PSMA, treating them by electrospinning, and then spraying an aqueous solution of fluorocarbon surfactant on them. The mass ratio of acidified carbon nanotubes to PSMA is 0.008:1; the diameter of carbon nanotubes is 40-50 nm, and the length is 5 μm-10 μm; the concentration of spinning solution for electrospinning is 25% (g / ml), and the voltage is 15KV, the distance between the electrospinning needle and the collecting plate is 9cm, the advancing speed is 0.05mm / min, the aqueous solution concentration of fluorocarbon surfactant is 2%; the relative molecular weight of PSMA is 30,000-80,000.

[0029] The preparation method of the above-mentioned oil-water separation non-woven fabric is to coat a layer of PSMA on the surface of the carbon nanotube by in-situ polymerization, and then react with the fluorocarbon sur...

Embodiment 2

[0043]The invention discloses an oil-water separation non-woven membrane material, which is made by grafting and coating carbon nanotubes after acidification treatment by PSMA, treating them by electrospinning, and then spraying an aqueous solution of fluorocarbon surfactant on them. The mass ratio of acidified carbon nanotubes to PSMA is 0.005:1; the diameter of carbon nanotubes is 60-80 nm, and the length is 10 μm-15 μm; the concentration of spinning solution for electrospinning is 35% (g / ml), and the voltage is 20KV, the distance between the electrospinning needle and the collecting plate is 10cm, the advancing speed is 0.01mm / min, the aqueous solution concentration of fluorocarbon surfactant is 3%; the relative molecular weight of PSMA is 90,000-150,000.

[0044] The preparation method of the above-mentioned oil-water separation non-woven fabric is to coat a layer of PSMA on the surface of the carbon nanotube by in-situ polymerization, and then react with the fluorocarbon s...

Embodiment 3

[0052] The invention discloses an oil-water separation non-woven membrane material, which is made by grafting and coating carbon nanotubes after acidification treatment by PSMA, treating them by electrospinning, and then spraying an aqueous solution of fluorocarbon surfactant on them. The mass ratio of acidified CNTs to PSMA is 0.01:1; the diameter of carbon nanotubes is 10-20 nm, and the length is 10 μm-15 μm; the concentration of spinning solution for electrospinning is 45% (g / ml), and the voltage is 18KV. The distance between the electrospinning needle and the collecting plate is 12cm, the advancing speed is 0.01mm / min, the aqueous solution concentration of fluorocarbon surfactant is 2%; the relative molecular weight of PSMA is 200,000-300,000.

[0053] The preparation method of the above-mentioned oil-water separation membrane is to coat a layer of PSMA on the surface of carbon nanotubes by in-situ polymerization, and then react with fluorocarbon surfactants through electro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com