Anti-sintering long-life double-layer columnar structure thermal barrier coating and preparation method thereof

A technology of thermal barrier coating and columnar structure, which is applied in coating, metal material coating process, fusion spraying, etc., can solve the problems of micropore healing and disappearance, and achieve the overcoming of significant decline in performance, strong feasibility, and rapid realization The effect of engineering application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

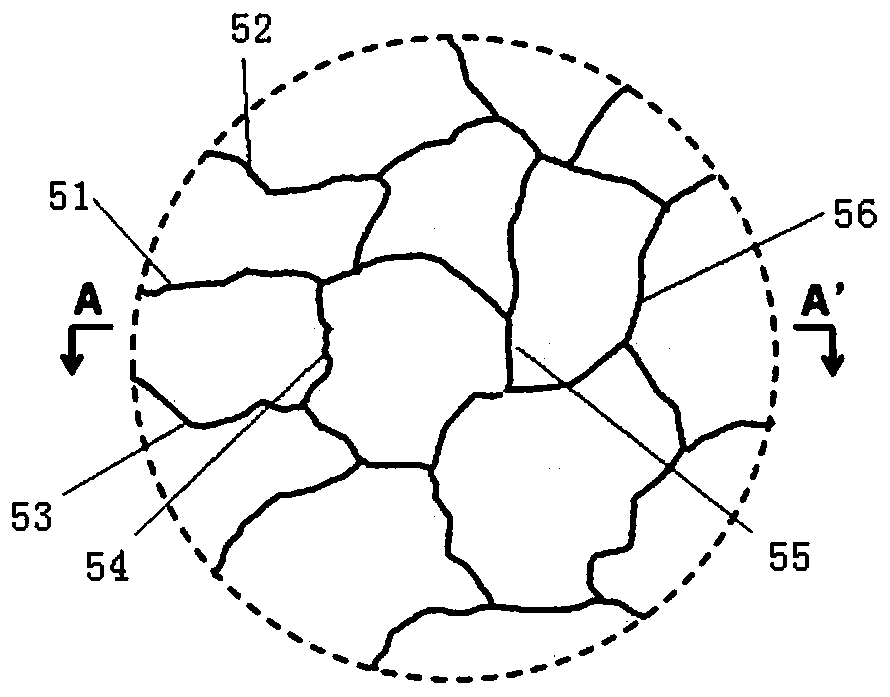

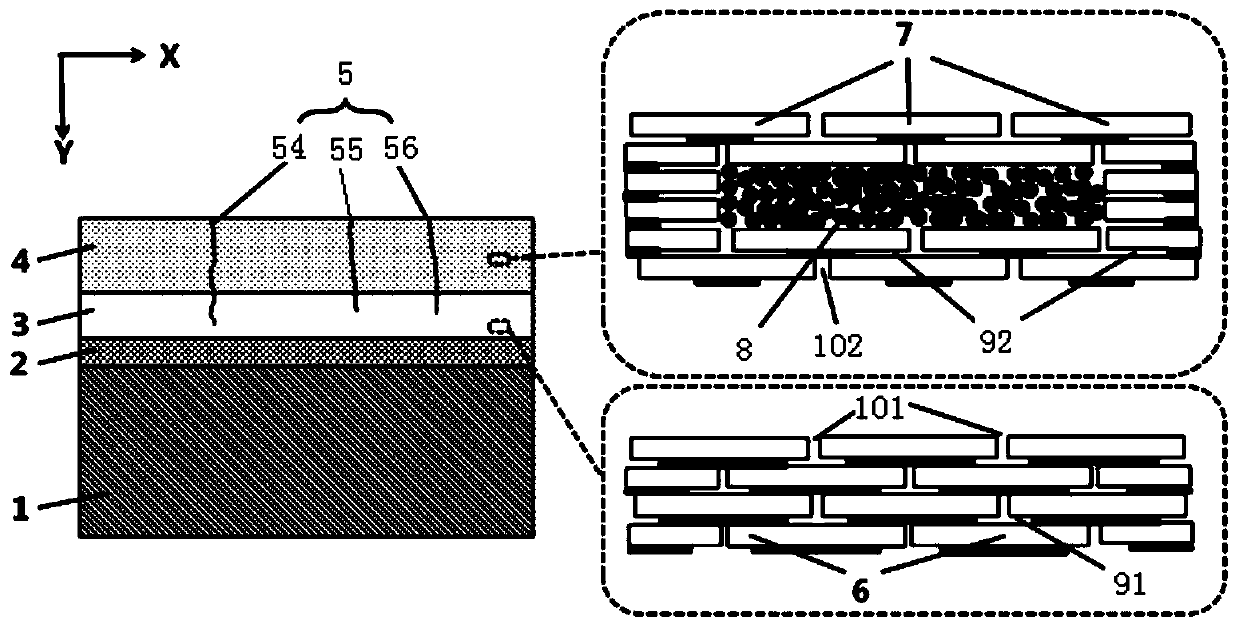

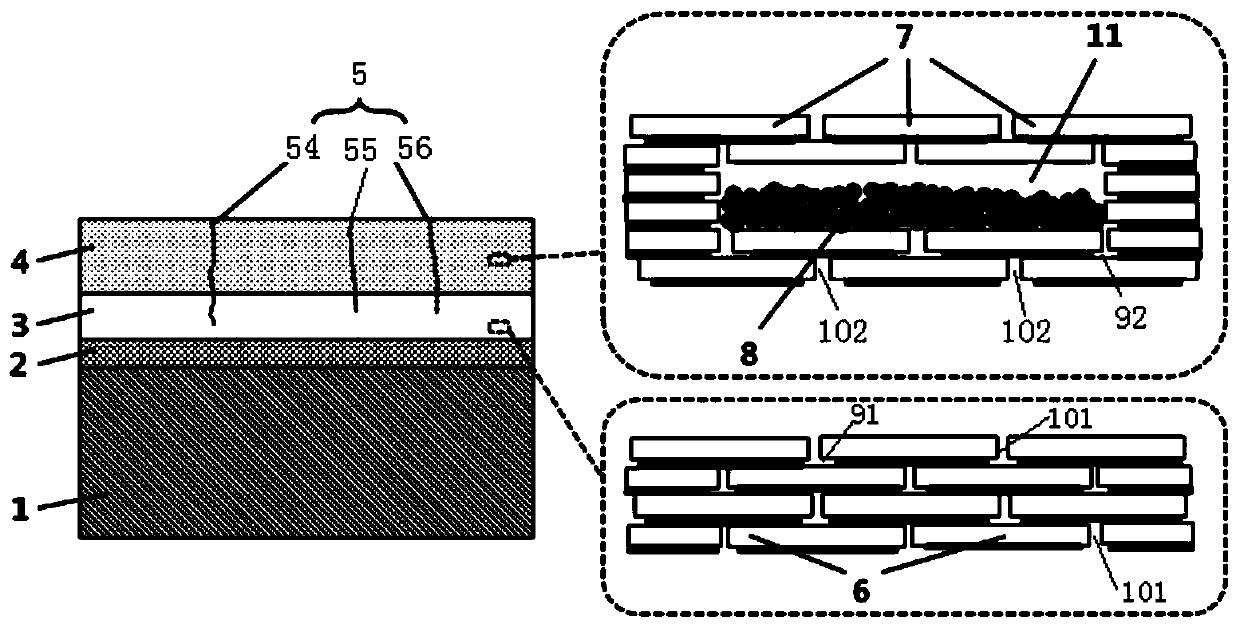

[0033] see figure 1 As shown, the present invention provides a method for preparing an anti-sintering long-life double-layer columnar structure thermal barrier coating, comprising the following steps:

[0034] Step 1. Prepare a metal bonding layer 2 with a thickness of 150 μm on the outer surface of the cylindrical superalloy substrate 1 by using a low-pressure plasma spraying process.

[0035] Step 2. On the metal bonding layer 2, 8YSZ smelting and crushing powder with a particle size of 5 μm to 25 μm is used to prepare a toughening layer 3 with a thickness of 150 μm by atmospheric plasma spraying. In the process of spraying, in order to make the interlayer bonding rate of the first layer unit 6 not lower than 50%, use a heating platform to preheat the substrate 1 and the metal bonding layer 2 to 400°C before spraying; the first layer The unit 6 has a dimension perpendicular to the direction of heat flow of 5 μm to 40 μm, and a dimension along the direction of heat flow of 0...

Embodiment 2

[0045] The difference between this embodiment and embodiment 2 is that in step 1, the thickness of the metal bonding layer 2 is 100 μm; in step 2, the temperature of the substrate is preheated to 300° C. during the deposition; During the process, the substrate temperature is controlled to not exceed 180°C.

Embodiment 3

[0047] The difference between this embodiment and embodiment 3 is that in step 1, the thickness of the metal bonding layer 2 is 125 μm; in step 2, the temperature of the substrate is preheated to 500° C. during the deposition; During the process, the substrate temperature is controlled to not exceed 160°C, and the liquid concentration of the nanometer YSZ dispersion is 5mol / L.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com