High-temperature-resistant adhesive tape

A technology of high temperature resistance and tape, applied in the direction of adhesives, film/sheet adhesives, etc., can solve the problems of tape not having high temperature resistance, separation of substrate and glue layer, no fire resistance, etc., to achieve excellent temperature insulation The effect of heat insulation, improved adhesion, and improved range of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

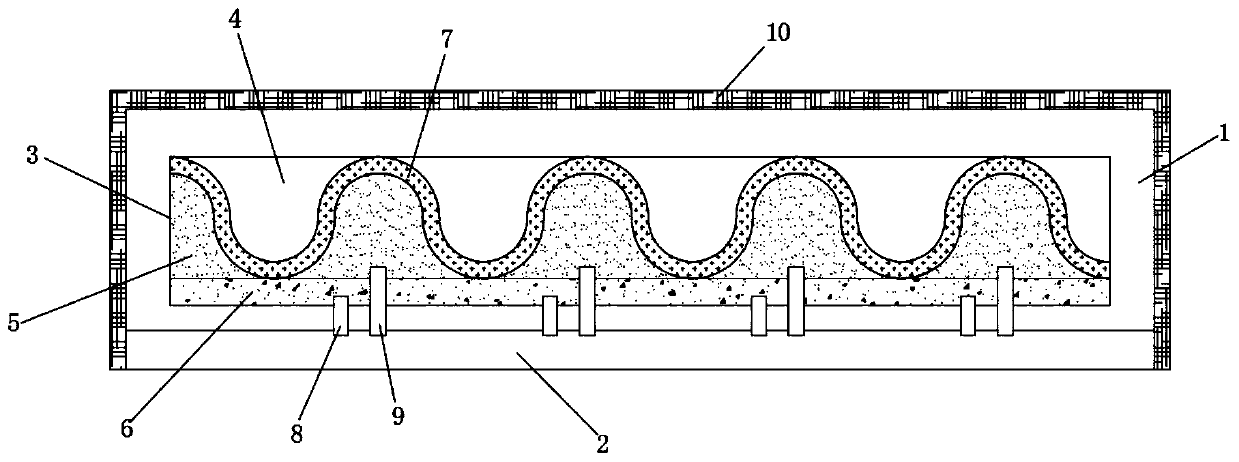

[0024] Such as figure 1 As shown, a high-temperature-resistant adhesive tape includes a base material 1 and a glue layer 2. The glue layer 2 is located at the bottom of the base material 1. A temperature-insulating layer 3 is arranged inside the base material 1. The temperature-insulating layer 3 is made of ceramic fiber interlayer 4, rock wool Interlayer 5 and phenolic resin interlayer 7 are composed, the bottom of ceramic fiber interlayer 4 is bonded with phenolic resin interlayer 7 , the bottom of phenolic resin interlayer 7 is bonded with rock wool interlayer 5 , the shape of phenolic resin interlayer 7 is set in an arc shape, and the bottom of temperature insulation layer 3 is Centrifugal glass wool interlayer 6 is bonded, substrate 1 has a thickness of 17 μm, temperature insulation layer 3 has a thickness of 10 μm, ceramic fiber interlayer 4 has a thickness of 4 μm, rock wool interlayer 5 has a thickness of 4 μm, and phenolic resin interlayer 7 has a thickness of The thi...

Embodiment 2

[0027] Such as figure 1 As shown, the bottom of the centrifugal glass wool interlayer 6 is provided with a through hole one 8 and a through hole two 9, the through hole one 8 is located on the side of the through hole two 9, the glue layer 2 is bonded to the centrifugal glass wool interlayer 6 through the through hole one 8, The glue layer 2 is bonded to the rock wool interlayer 5 through the centrifugal glass wool interlayer 6 through the through hole two 9, the diameter of the through hole one 8 is 4 μm, and the length of the through hole one 8 is 1 μm, and the diameter of the through hole two 9 is 4 μm , and the length of the second through hole 9 is 4 μm.

[0028] In this embodiment, by setting the first through hole 8 and the second through hole 9, the adhesion between the glue layer 2 and the base material 1 can be effectively improved, and the glue layer 2 and the base material 1 can be prevented from being separated from the glue layer 2 after long-term use of the adhe...

Embodiment 3

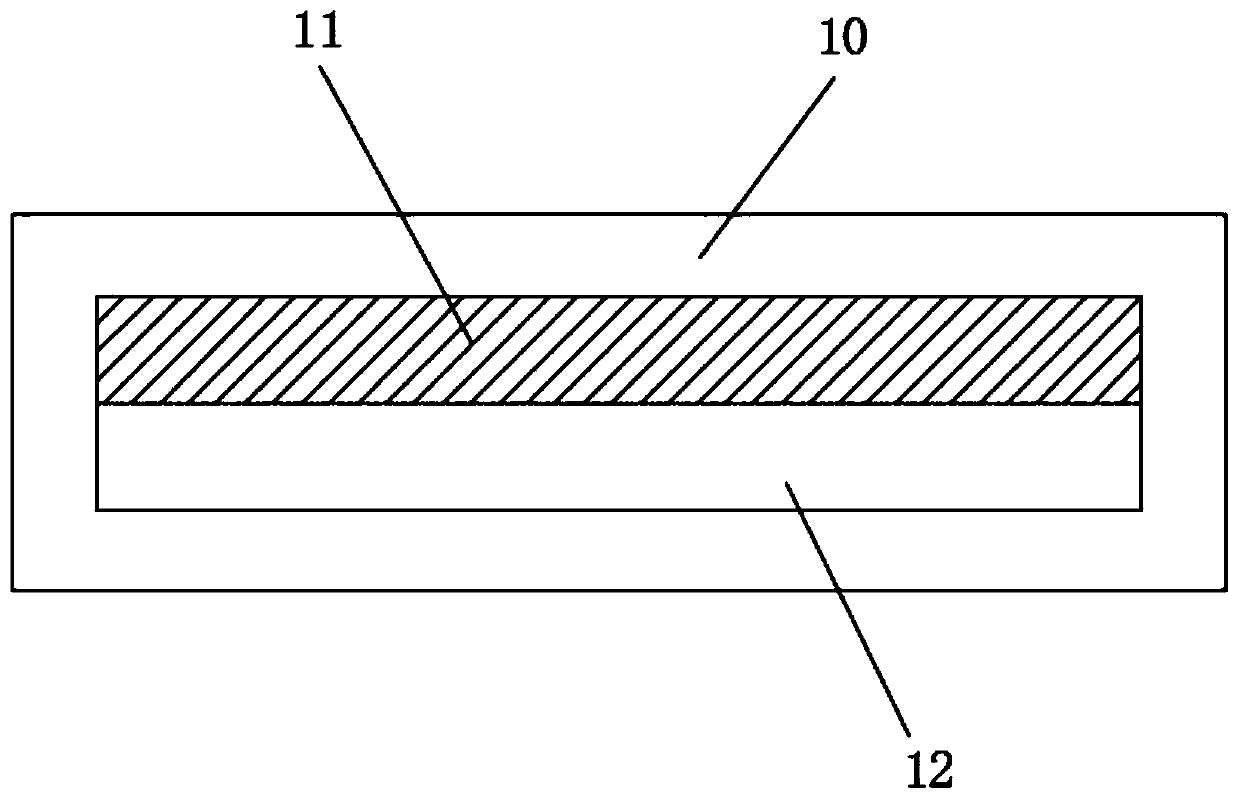

[0030] Such as Figure 1-2 As shown, the outer surface of the substrate 1 is provided with a fireproof layer 10, the fireproof layer 10 is composed of a fireproof flame retardant coating 11 and a fireproof coating 12, the fireproof flame retardant coating 11 is located on one side of the fireproof coating 12, and the fireproof layer 10 The thickness of the fire retardant coating 11 is 5 μm, the thickness of the fire retardant coating 11 is 2.5 μm, and the thickness of the fire protection coating 12 is 2.5 μm.

[0031] In this embodiment, the fireproof and flame retardant properties of the adhesive tape are effectively improved through the fireproof layer 10 .

[0032] It should be noted that the present invention is a high temperature resistant adhesive tape. During operation, the temperature insulation layer 3 inside the substrate 1 includes ceramic fiber interlayer 4, rock wool interlayer 5 and phenolic resin interlayer 7, all of which have very good high temperature resista...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com