Photoreversible self-healing solvent-free polyurethane composition, synthetic leather bass and preparation method of synthetic leather bass

A solvent-free polyurethane, self-healing technology, applied in the field of polyurethane, can solve the problems of easy hydrolysis and undurable coating, and achieve the effects of mild repair conditions, extended service life and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

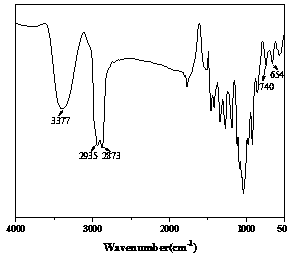

Method used

Image

Examples

Embodiment 1

[0028] Step 1: Under the protection of inert gas, mix 10g of isophorone diisocyanate (IPDI) and 21.6g of trifunctional polypropylene glycol (Mn=6000) evenly, and react at 70°C for 2h, measure the -NCO in the system The content determines the end point of the reaction, and the obtained-NCO content is the terminal isocyanate prepolymer B component of 11%;

[0029] Step 2: Under magnetic stirring in an ice bath, add selenium powder to deionized water containing dissolved sodium borohydride, the molar ratio of selenium powder and sodium borohydride is 2:1, stir the mixture for 15 minutes, and place in a steam bath After further warming, 2-bromoethanol was injected into the solution under the protection of nitrogen. React at 50°C for 6h and cool to room temperature, extract, and use anhydrous Na 2 SO 4 dry. Purification by column chromatography affords diselenodiol.

[0030] Step 3: Under the protection of an inert gas, stir components A such as diselenediol, organic bismuth ca...

Embodiment 2

[0033] Step 1: Under the protection of an inert gas, mix 10g of isophorone diisocyanate (IPDI) and 19.3g of trifunctional polypropylene glycol (Mn=6000) evenly, and react at 75°C for 3 hours to measure the - The content of NCO determines the end point of the reaction, and the obtained-NCO content is the terminal isocyanate prepolymer B component of 12%;

[0034] Step 2: Under magnetic stirring in an ice bath, add selenium powder to deionized water containing dissolved sodium borohydride, the molar ratio of selenium powder and sodium borohydride is 2:1, stir the mixture for 18 minutes, and place in a steam bath After further warming, 2-bromoethanol was injected into the solution under the protection of nitrogen. React at 50°C for 7h and cool to room temperature, extract, and use anhydrous Na 2 SO 4 dry. Purification by column chromatography affords diselenodiol.

[0035] Step 3: Under the protection of an inert gas, stir components A such as diselenide, organic bismuth cata...

Embodiment 3

[0038] Step 1: Under the protection of an inert gas, mix 10g of isophorone diisocyanate (IPDI) and 17.2g of trifunctional polypropylene glycol (Mn=6000) evenly, and react at 80°C for 3 hours to measure the - The content of NCO determines the end point of the reaction, and the obtained-NCO content is the terminal isocyanate prepolymer B component of 13%;

[0039] Step 2: Under magnetic stirring in an ice bath, add selenium powder to deionized water containing dissolved sodium borohydride, the molar ratio of selenium powder and sodium borohydride is 2:1, stir the mixture for 20 minutes, and place in a steam bath After further warming, 2-bromoethanol was injected into the solution under the protection of nitrogen. React at 50°C for 8h and cool to room temperature, extract, and use anhydrous Na 2 SO 4dry. Purification by column chromatography affords diselenodiol.

[0040] Step 3: Under the protection of an inert gas, stir components A such as diselenide, organic bismuth catal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com