Screw rod for extrusion foaming device and extrusion foaming device

A technology of extrusion foaming and screw, which is applied in the field of screw for extrusion foaming devices, which can solve the problem of inability to ensure effective and stable injection of foaming agent into polymer/uniform mixing of foaming agent, failure to ensure effective and stable injection of foaming agent, Problems such as uneven mixing of polymers and foaming agents can achieve the effect of increasing the pressure difference, improving the quality of finished products, and increasing the number of foaming nuclei

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

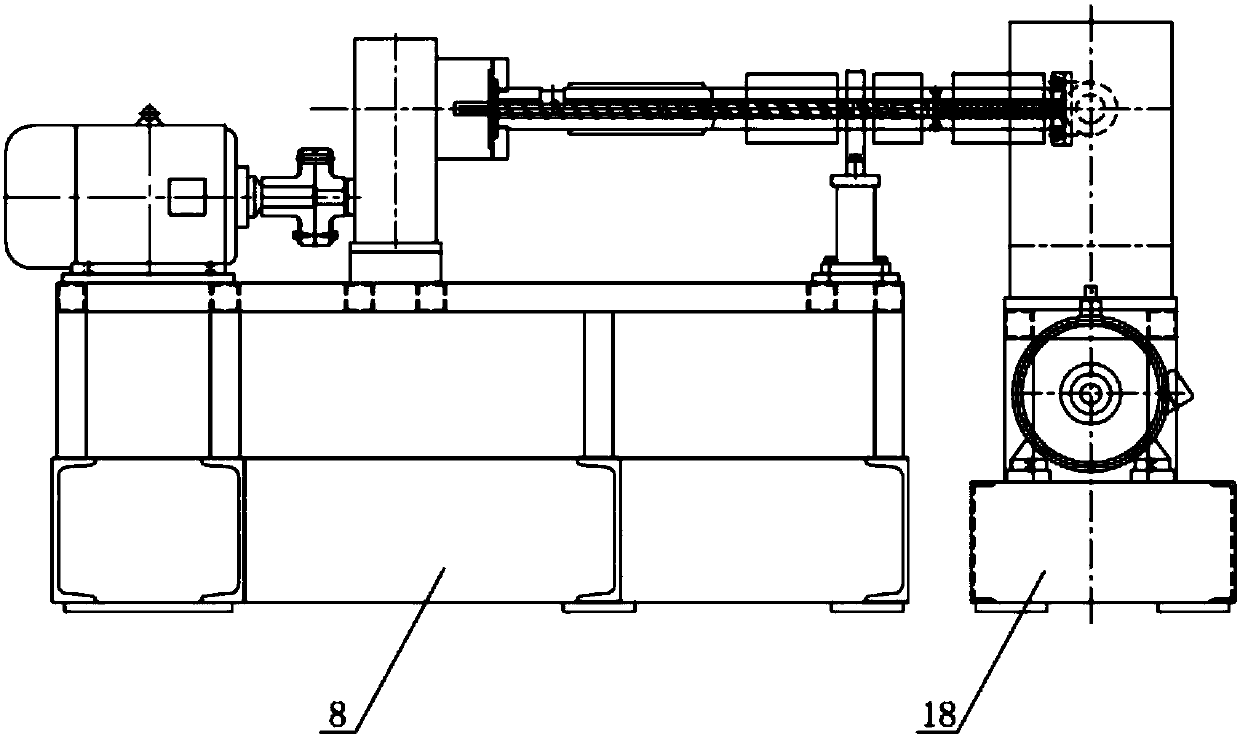

[0062] The raw material is polystyrene, the foaming agent is supercritical carbon dioxide, and the gas injection rate of carbon dioxide is 5ml / min; 180°C, on the second extruder 18: 180°C, 170°C, 160°C, 150°C, 140°C, the temperature of the foaming die 26 is 110-140°C; the screw speed of the first extruder 8 is 25 rpm Minutes, the screw speed of the second extruder 18 is 3 revs / min; Adopt capillary die, and the diameter of its discharge slit 28 is 2mm.

[0063] The performance indicators of the polystyrene foamed strips obtained in this example are as follows: the cell diameter is 5-40 μm, and the cell density is 5.0×10 8 ~1.2×10 9 cells / cm 3 , The expansion ratio is 10-25 times.

Embodiment 2

[0065] The raw material is polypropylene, the nucleating agent is nano silicon dioxide, the addition amount is 0.5% to 2.5% (mass ratio), the foaming agent is carbon dioxide, and the gas injection rate of carbon dioxide is 4ml / min; The heating temperature is set in sequence: first extruder 8: 190°C, 195°C, 195°C, second extruder 18: 195°C, 190°C, 180°C, 175°C, 170°C, foaming die 26 The temperature is 140-170°C; the screw speed of the first extruder 8 is 30 rpm, and the screw speed of the second extruder 18 is 2 rpm; a foaming flat slot die is adopted, and the discharge slot 28 The gap is 0.5-1.5mm.

[0066] The performance indicators of the polypropylene foam sheet obtained in this example are as follows: the cell diameter is 20-150 μm, and the cell density is 6.0×10 6 ~2.0×10 8 cells / cm 3 , The foaming ratio is 5 to 12 times.

Embodiment 3

[0068] The raw material is polyvinyl alcohol 1799; the plasticizer is water and glycerin, and the crosslinking agent is boric acid, wherein the plasticizer is added in an amount of 10% to 30% (mass ratio), and the crosslinker is added in an amount of 0.25 to 30%. 2% (mass ratio), the foaming agent is carbon dioxide, and the gas injection rate of carbon dioxide is 2.5ml / min; in the circulating cooling section 16 on the first extruder 8, a circulating cooling liquid with a temperature of about 50°C is added, and each The heating temperature of the heating section is set in turn: on the first extruder 8: 170°C, 180°C, 180°C, on the second extruder 18: 180°C, 175°C, 170°C, 160°C, 150°C, foaming The temperature of the die 26 is 105-140°C; the screw speed of the first extruder 8 is 15 rpm, and the screw speed of the second extruder 18 is 2 rpm; a foaming ring die is adopted, and the discharge seam 28 gap is 0.75 ~ 2mm.

[0069] The performance indicators of the polyvinyl alcohol fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com