Multifunctional tool head shifting mechanism

A tool head and multi-functional technology, applied in the field of multi-function tool head switching mechanism, can solve the problems of inability to realize flexible conversion of multiple tool heads, complex processing technology, small adjustment angle, etc., and achieve easy and smooth advancement, The effect of flexible conversion and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

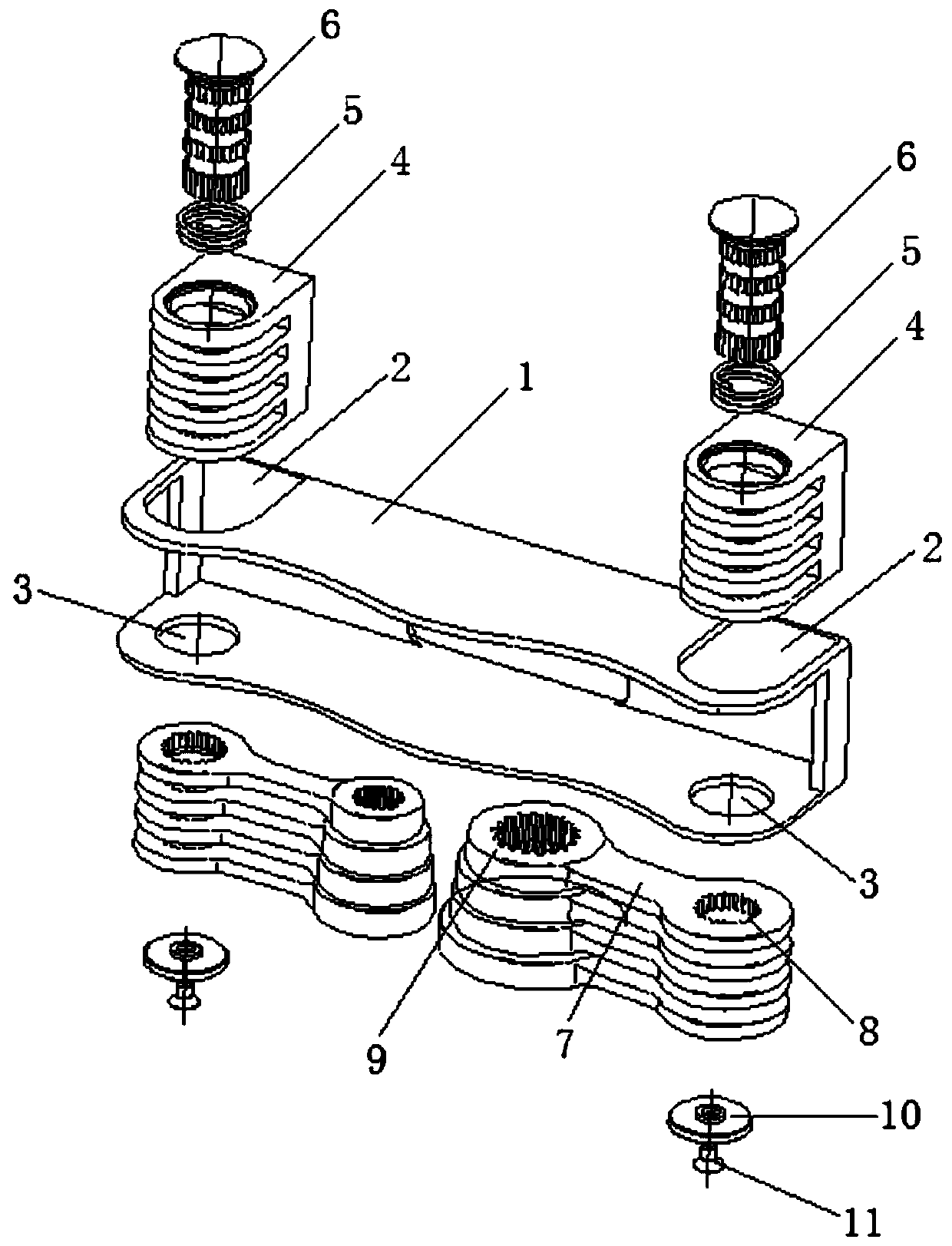

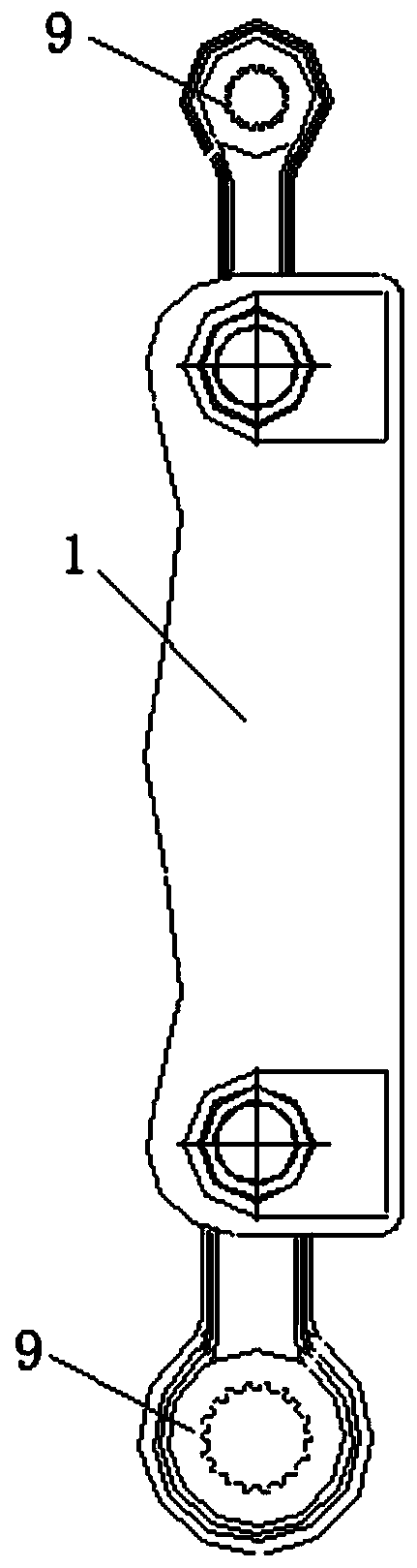

[0045] Such as figure 1 , figure 2 , Figure 6 to Figure 10 A multifunctional tool head switching mechanism shown includes:

[0046] Mounting bracket 1, said mounting bracket 1 includes a pair of symmetrically arranged side plates and bottom plates, wherein the two ends of one side plate are respectively provided with first through holes 2 for accommodating U-shaped support 4, and the other side plate The two ends of each are respectively provided with second through holes 3 for accommodating the caps 10 to be installed.

[0047] In this embodiment, the shape of the first through hole 2 is consistent with the shape of the U-shaped support 4 , and the shape of the second through hole 3 is consistent with the shape of the cap 10 .

[0048] U-shaped support 4, the U-shaped support 4 is successively provided with a third through hole 42 coaxially arranged to place a return spring, three smooth fourth through holes 43 and a splined hole at the end. The fifth through hole 45, t...

Embodiment 2

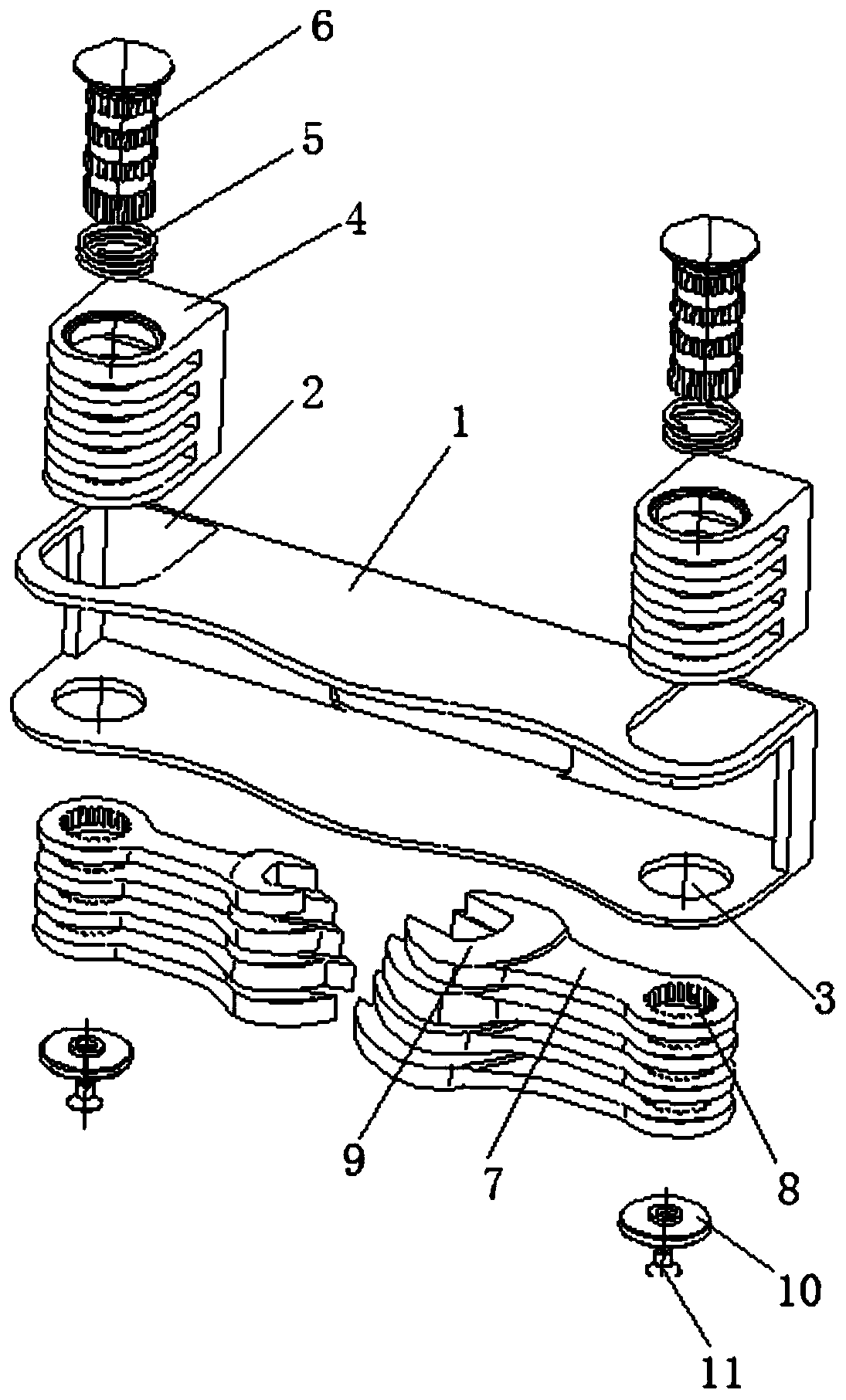

[0054] Such as image 3 , Figure 4 , Figure 6 to Figure 10 A multifunctional tool head switching mechanism shown includes:

[0055] Mounting bracket 1, said mounting bracket 1 includes a pair of symmetrically arranged side plates and bottom plates, wherein the two ends of one side plate are respectively provided with first through holes 2 for accommodating U-shaped support 4, and the other side plate The two ends of each are respectively provided with second through holes 3 for accommodating the caps 10 to be installed.

[0056] In this embodiment, the shape of the first through hole 2 is consistent with the shape of the U-shaped support 4 , and the shape of the second through hole 3 is consistent with the shape of the cap 10 .

[0057] U-shaped support 4, the U-shaped support 4 is successively provided with a third through hole 42 coaxially arranged to place a return spring, three smooth fourth through holes 43 and a splined hole at the end. The fifth through hole 45, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com