Air purifying filter element based on modified glass fiber framework and preparation method of air purifying filter element

A glass fiber and air purification technology, applied in chemical instruments and methods, separation methods, dispersed particle filtration, etc., can solve the problem of inconvenient removal of filter elements, and achieve the effects of enhancing toughness, preventing bacteria and mildew, and reducing the number of cleanings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

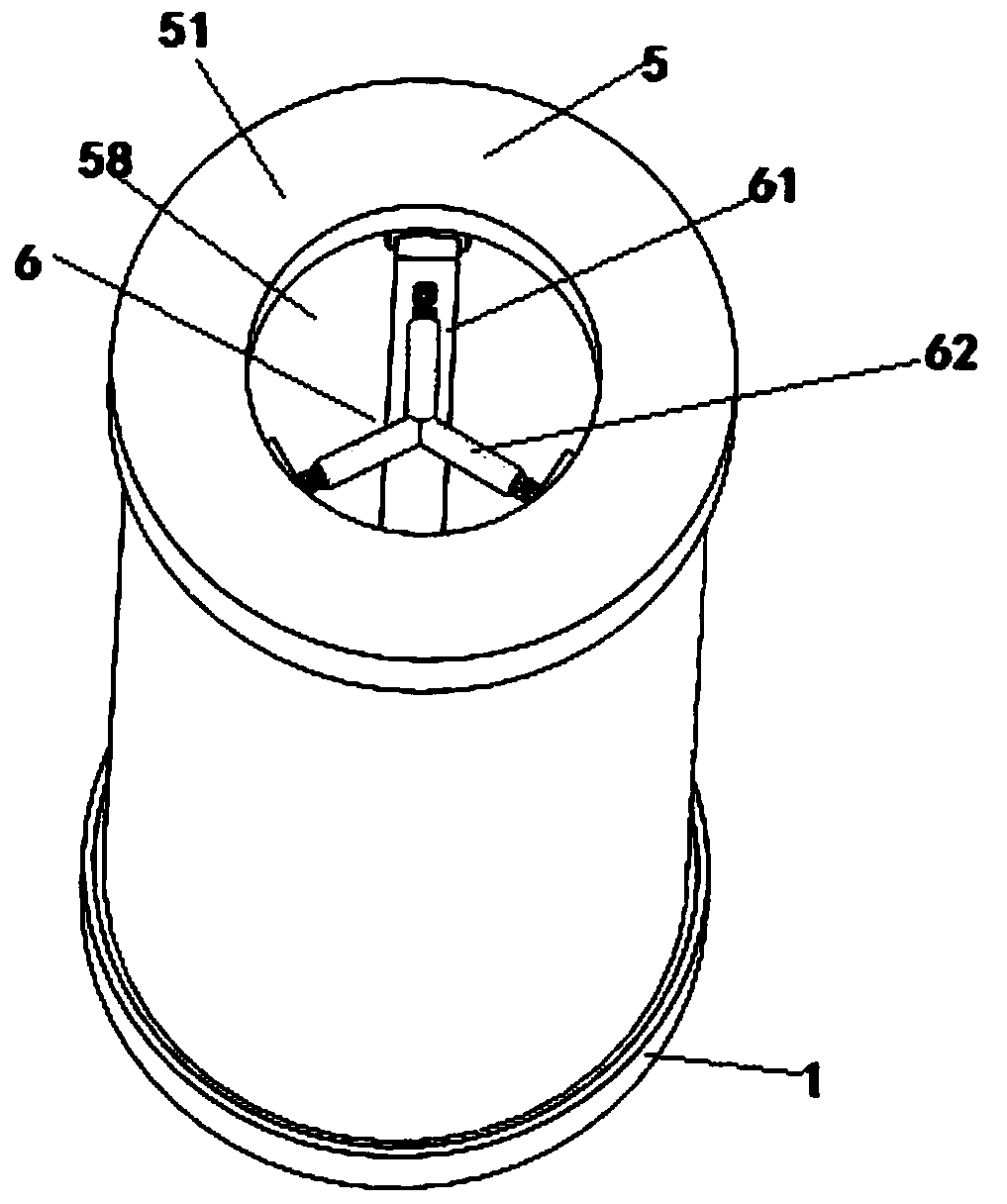

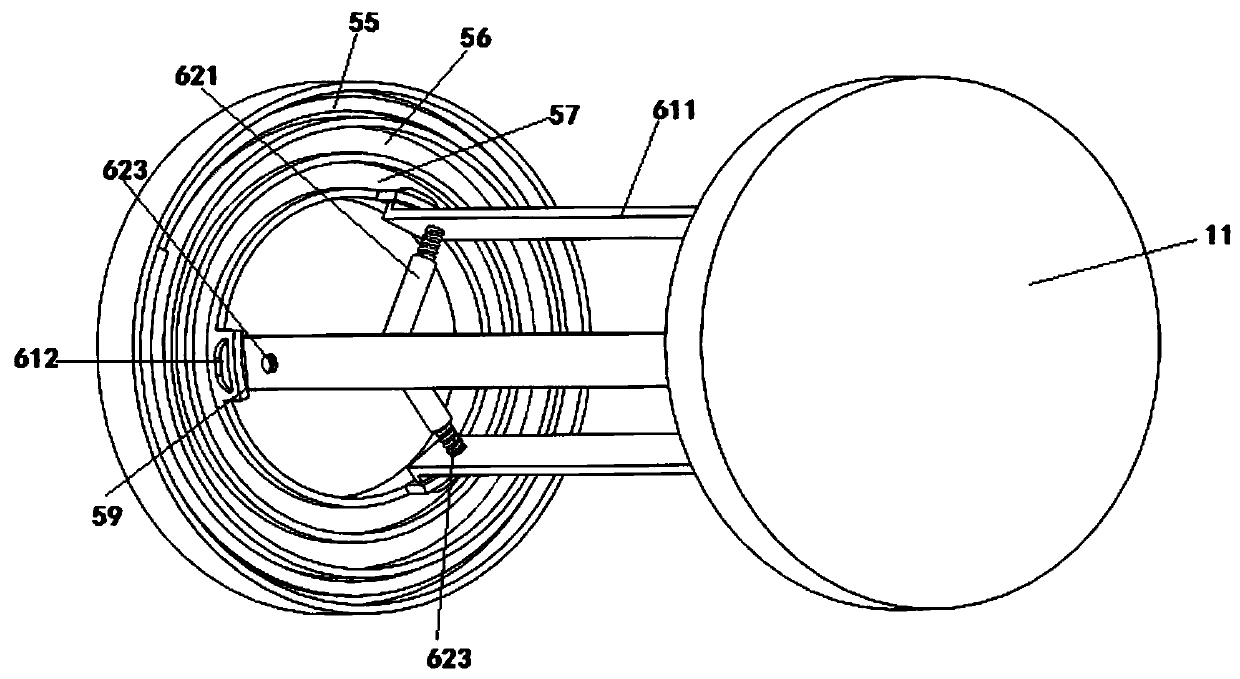

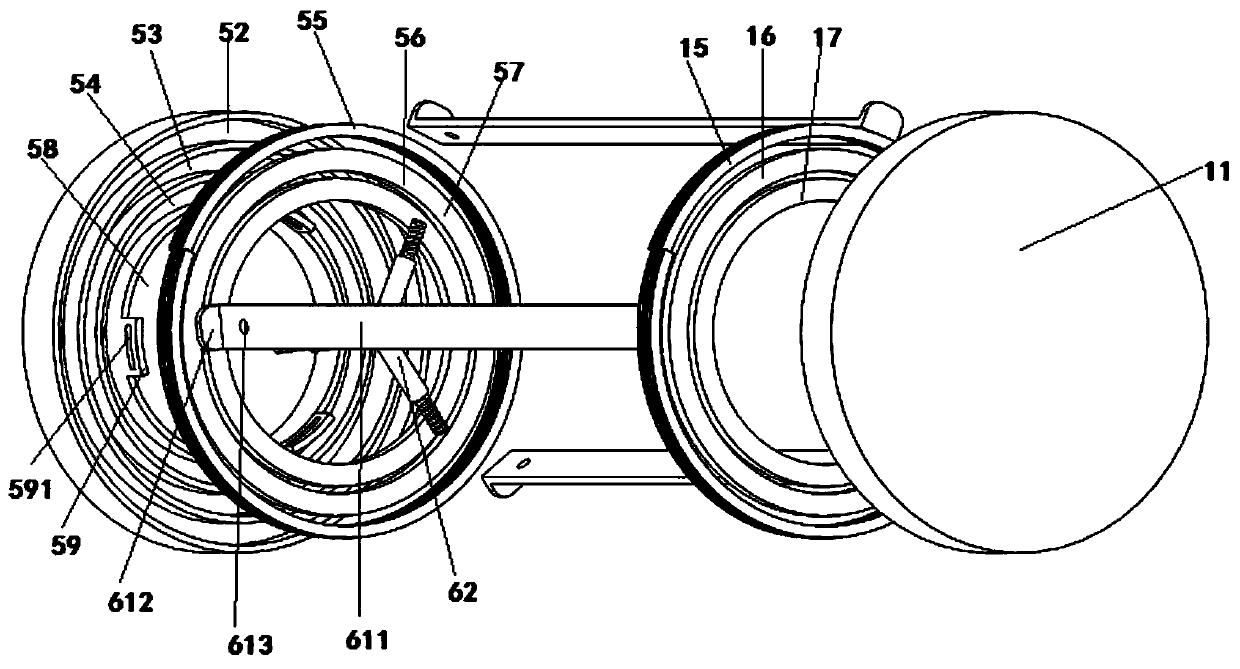

[0038] An air purification filter element based on a modified glass fiber skeleton, such as Figure 1-5 As shown, it includes a vibration-sealed base 1, and the vibration-sealed base 1 is sequentially installed and fixed with a coarse-effect filter element 2, an activated carbon filter element 3 and a HEPA high-efficiency filter element 4. At the same time, the coarse-effect filter element 2 and the activated carbon filter element 3 and the top of the HEPA high-efficiency filter core 4 are installed on the top pressure seat 5, and the vibration sealing base 1 and the top pressure seat 5 are connected and fixed by a positioning connection fixing mechanism 6;

[0039] The vibration-seal base 1 includes a bottom plate 11, and the surface of the bottom plate 11 is sequentially provided with a first bottom ring groove 12, a second bottom ring groove 13 and a third bottom ring groove 14; wherein the first bottom ring groove 12, the second bottom ring groove The bottom ring groove 13...

Embodiment 2

[0053] The modified glass fiber filter screen is made of modified glass fiber, and the specific preparation process of the modified glass fiber is as follows:

[0054] Step 1, add 100g of neutral polyamide resin into 4L of dimethylformamide and stir to dissolve, then add 12g of nano-titanium dioxide to it, stir and mix evenly to obtain a bonding solution; wherein 40-45mL of dimethicone is added to each gram of neutral polyamide resin In methylformamide;

[0055] Step 2: Add 120g of glass fiber to 1L of bonding solution, then add 23g of 2,3-epoxypropyltrimethylammonium chloride to it, raise the temperature to 60-70°C and ultrasonically shake for 3-4h, then drop by drop Add 33.8g of isophorone diisocyanate, ultrasonicate while adding dropwise, react at a constant temperature for 1-1.5h after the dropwise addition is complete, then cool down to room temperature, remove the glass fiber, and dry it in an oven at 40-50°C to obtain Modified glass fibers.

[0056] Testing the modifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com