Preparation method for making soy sauce through yellow slurry

A technology for brewing soy sauce and yellow syrup, which is applied in the field of condiments, can solve the problems of high production costs, etc., and achieve the effects of saving processing costs, increasing yields, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The present embodiment provides a method for brewing soy sauce using yellow syrup water, the method is as follows:

[0047] (1) Select non-transgenic high-quality soybeans with large bean granules and full particles; select flour with a grade of standard flour.

[0048] (2) After soaking the soybeans for 6 hours, put them into the basket and filter the water for 2 hours, and cook the soybeans at a pressure of 0.1 MPa and a temperature of 121°C for 40 minutes, and keep the temperature and pressure for 2 hours to obtain soybean clinker. When the soybean clinker is naturally cooled to 60°C in the cooling tank, it is evenly mixed with the flour that has been fried for 15 minutes. Among them, the mass ratio of soybean clinker and flour is 6:4.

[0049] (3) When the mixture is cooled to 35°C, inoculate 3.951 Aspergillus oryzae with a mass ratio of 0.03%, stir evenly, culture at 30°C for 42 hours, and turn the koji material once every 4-6 hours to obtain the koji material; W...

Embodiment 2

[0055] The present embodiment provides a kind of method that uses yellow pulp water to brew soy sauce, and the method is as follows:

[0056] (1) Select non-genetically modified high-quality soybeans with large and full grains; select flour with a grade of standard flour.

[0057] (2) After soaking the soybeans for 6 hours, put them into a basket to filter water for 2 hours, cook the soybeans at a pressure of 0.1 MPa and a temperature of 105° C. for 30 minutes, hold heat and pressure for 3 hours, and obtain soybean clinker. When the soybean clinker is naturally cooled to 60°C in the cooling tank, it is evenly mixed with the flour fried for 15 minutes. Wherein, the mass ratio of soybean clinker to flour is 5:4.

[0058] (3) When the mixed material is cooled to 35°C, inoculate 3.951 Aspergillus oryzae koji essence with a mass ratio of 0.01%, after stirring evenly, cultivate at 28°C for 48 hours, and turn the koji once every 4 to 6 hours to obtain the koji material; The seasoni...

experiment example

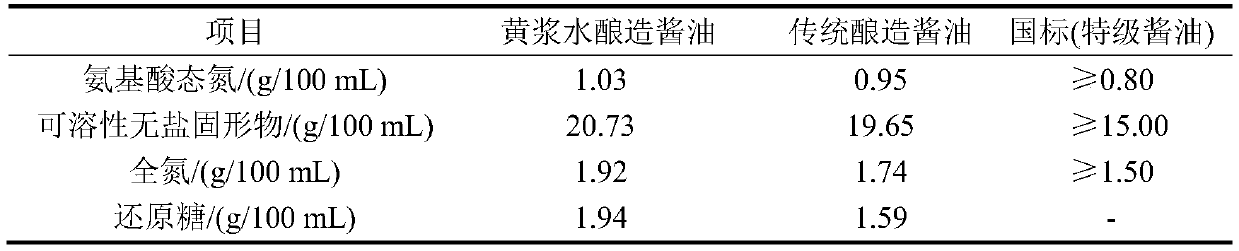

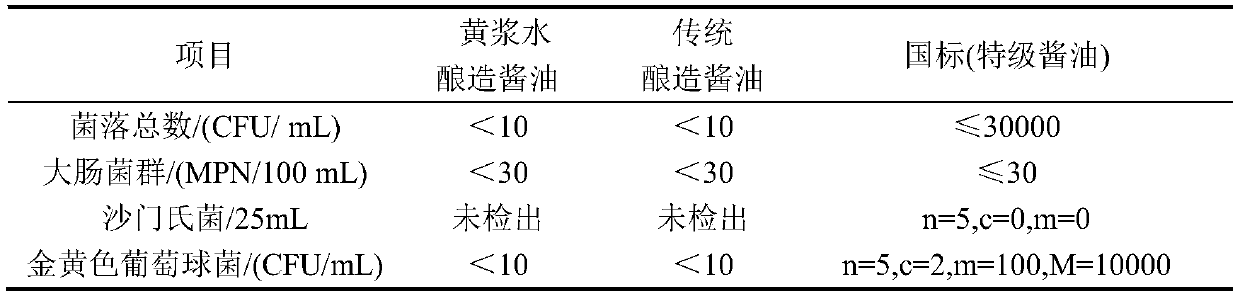

[0066] The quality (sensory index, physicochemical index, microbiological index, volatile index, physical and chemical index, microbiological index, volatility of the fermented 180d yellow pulp water brewed soy sauce and traditional brewed soy sauce made by embodiment 1 (yellow pulp water brewed soy sauce) and comparative example 1 (traditional brewed soy sauce) Aroma components and free amino acid composition) were analyzed.

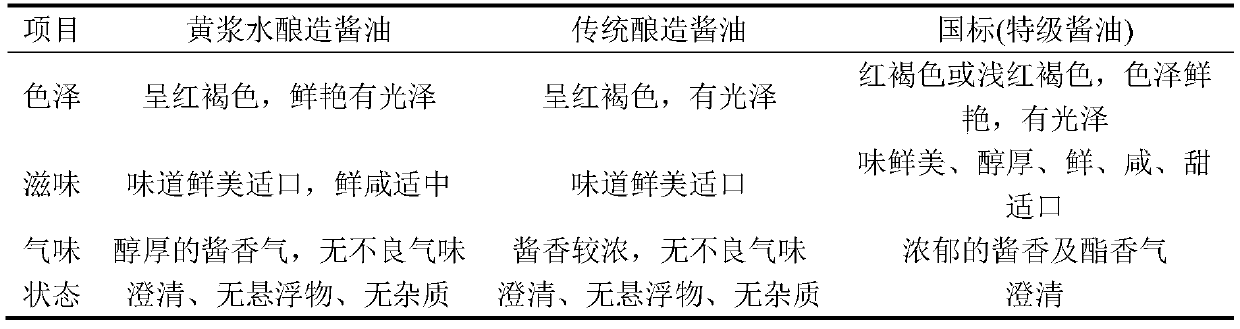

[0067] (1) Sensory index test

[0068] The sensory indicators such as color, aroma, taste, and body shape of yellow pulp water brewed soy sauce and traditional brewed soy sauce were tested. The results are shown in Table 1. The color of the soy sauce brewed with yellow pulp water is reddish brown and shiny; the sauce has a strong aroma and no bad smell; The sensory indicators of soy sauce brewed with yellow pulp water are consistent with those of traditional brewed soy sauce, and both meet the standard of extra-grade soy sauce in GB18186-2000 "Brewed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com