Puffed mixed raw material, processing method thereof and compound feed prepared by using same

A technology of mixing raw materials and processing methods, applied in the molding or processing of animal feed, animal feed, animal feed, etc., can solve the problems of low growth performance and high diarrhea rate of weaned piglets, and achieve increased labor force, good palatability, and popularization. efficiency and high utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

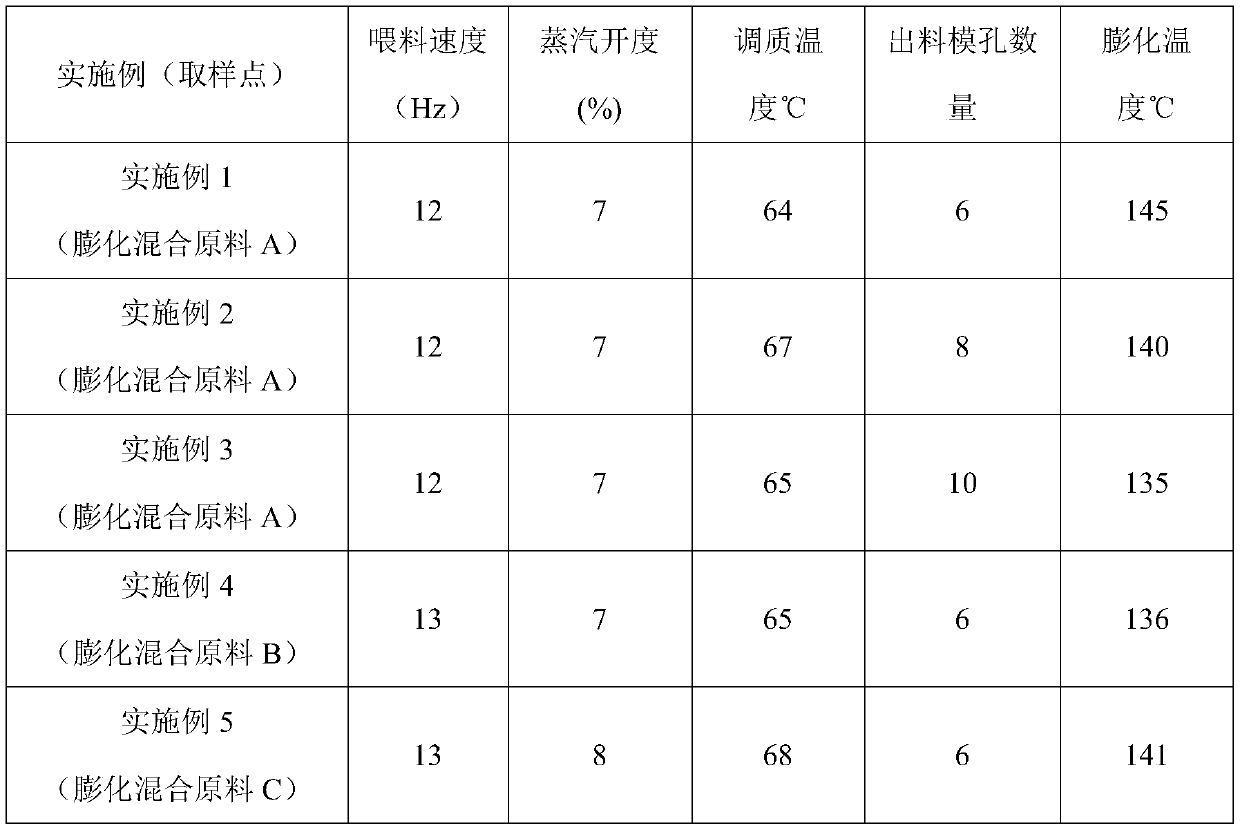

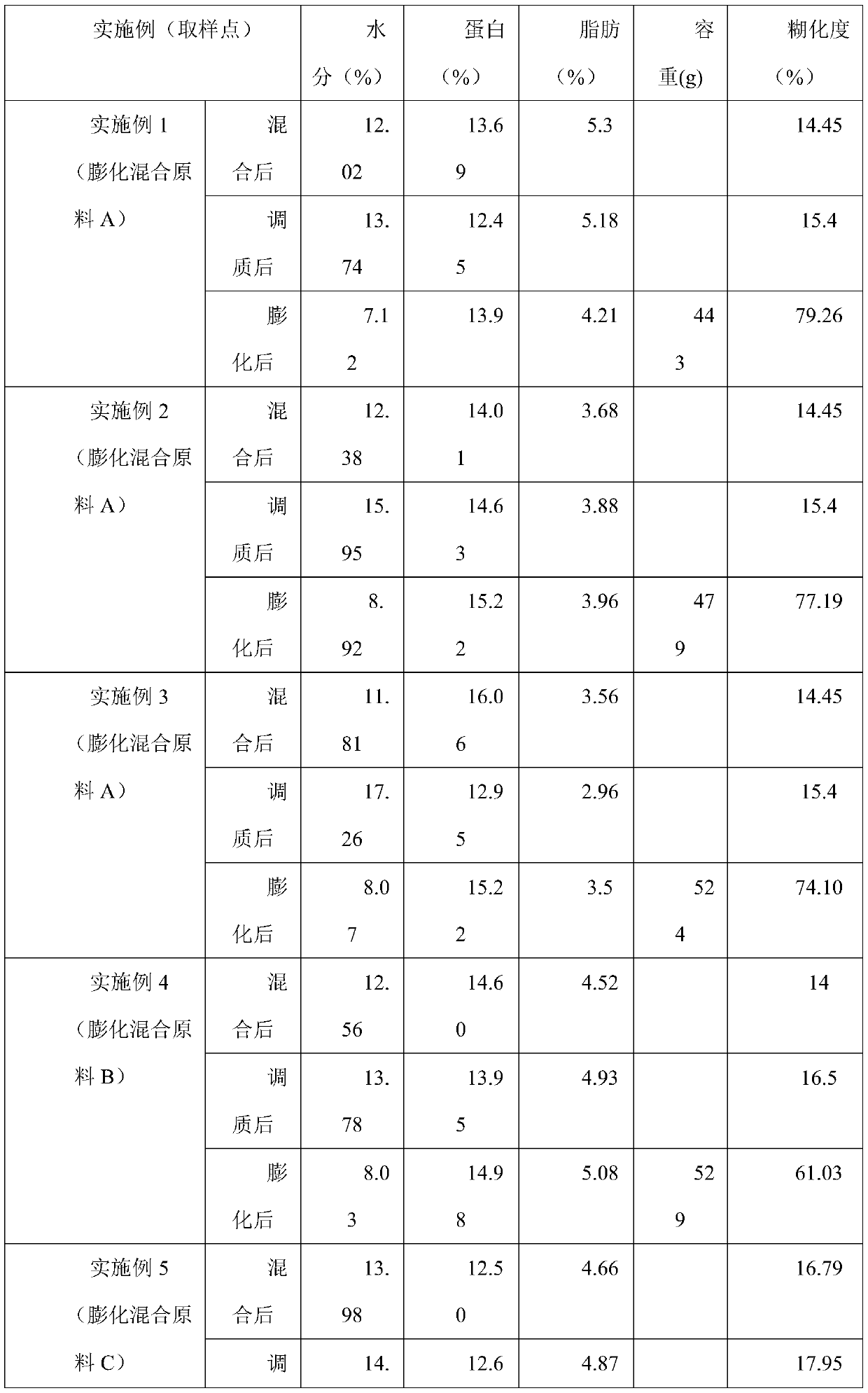

Embodiment 1

[0036]The puffed mixed raw material of the present invention is made of pretreated corn, broken rice, soybean meal, mixed with vegetable oil according to the mass ratio of 420:400:165:15, puffed at a high temperature of 145°C, cooled and crushed owned.

[0037] The processing method of above-mentioned puffed mixed raw material, specifically carries out according to the following steps:

[0038] Step 1: Pretreatment of a single raw material: Obtain a single raw material, namely corn, broken rice, and soybean meal; remove impurities and iron from the single raw material corn, broken rice, and soybean meal, and then follow the crushing parameters of 1.2x1.2mm (crushing particle size) crushing it separately to obtain a single raw material to be prepared after pretreatment;

[0039] The second step: mixing: the single raw material corn, broken rice, soybean meal, and vegetable oil crushed in the previous step are mixed according to the mass ratio of 420:400:165:15 (about 28:27:11:...

Embodiment 2、 Embodiment 3

[0044] Same as the puffed mixed raw material of Example 1, the difference from the processing method of Example 1 lies in the difference in the number of discharge die openings and the puffing temperature.

Embodiment 4

[0046] The puffed mixed raw material of the present invention is made of pretreated corn, broken rice, soybean meal, mixed with vegetable oil according to the mass ratio of 400:380:200:20, puffed at a high temperature of 136°C, cooled and crushed owned.

[0047] The processing method of above-mentioned puffed mixed raw material, specifically carries out according to the following steps:

[0048] Step 1: Pretreatment of a single raw material: Obtain a single raw material, namely corn, broken rice, and soybean meal; remove impurities and iron from the single raw material corn, broken rice, and soybean meal, and then follow the crushing parameters of 1.2x1.2mm (crushing particle size) crushing it separately to obtain a single raw material to be prepared after pretreatment;

[0049] The second step: mixing: the single raw material corn, broken rice, soybean meal and vegetable oil crushed in the previous step are mixed according to the mass ratio of 400:380:200:20 (ie 20:19:10:1),...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com