Printed circuit-type heat exchanger having integral structure

A technology of printed circuit boards and heat exchangers, applied in the direction of heat exchanger fixation, printed circuit components, circuit heating devices, etc., can solve the problems of heat loss, pressure, loss, etc., to reduce the number of parts, simplify the structure, and shorten the production the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0073] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be mentioned here that the interpretation of the terms or words used in this specification and claims should not be limited to the usual meaning or dictionary meaning, but should be interpreted in accordance with the meaning and concept of the technical idea of the present invention.

[0074] Throughout this specification, when it is referred to that a certain member is located “on” another member, it includes not only a case where a certain member touches another member, but also a case where another member exists between the two members. Throughout this specification, when it is stated that a certain part "comprises" a certain constituent element, it means that other constituent elements can be included without excluding other constituent elements, unless the contrary content is specifically stated.

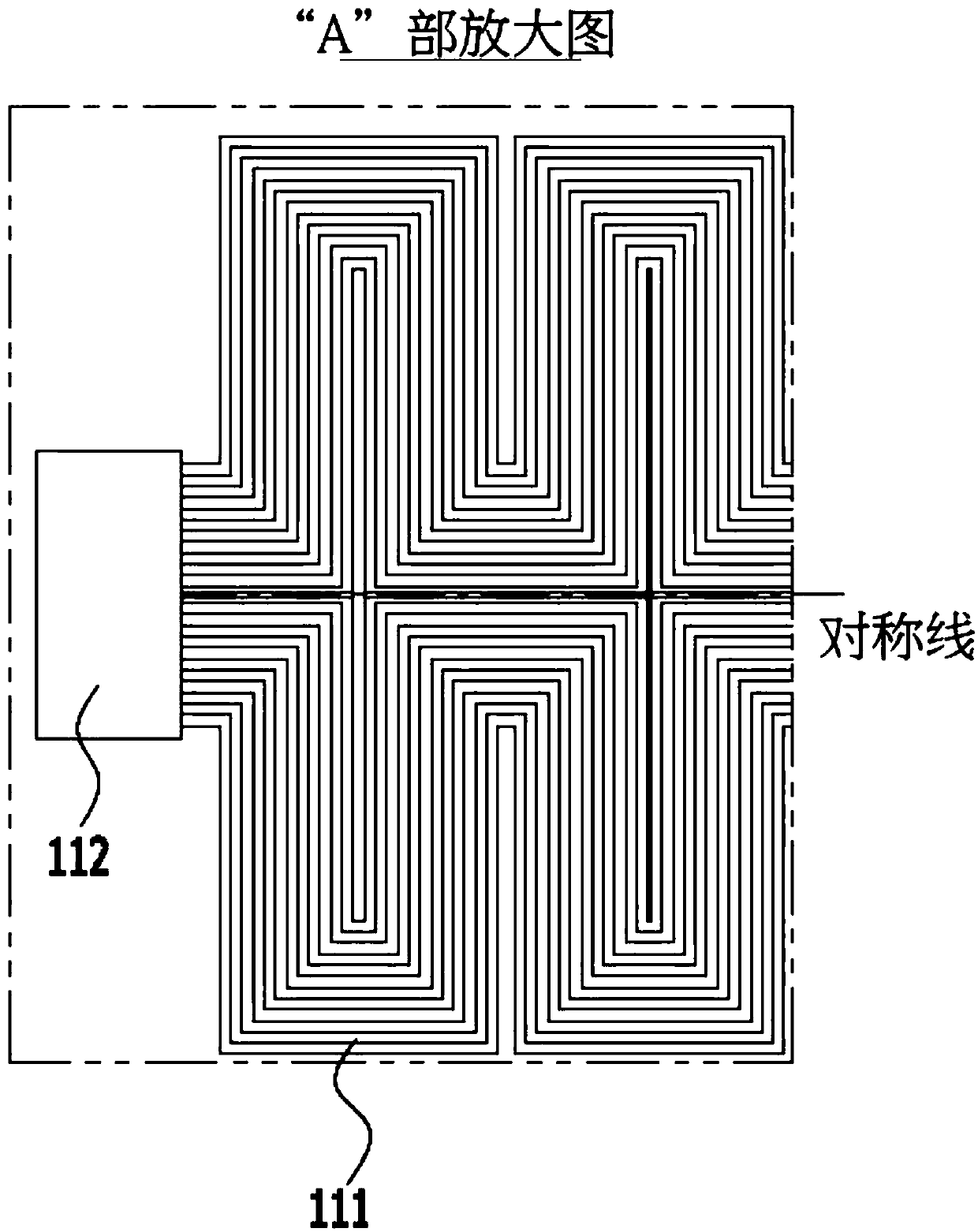

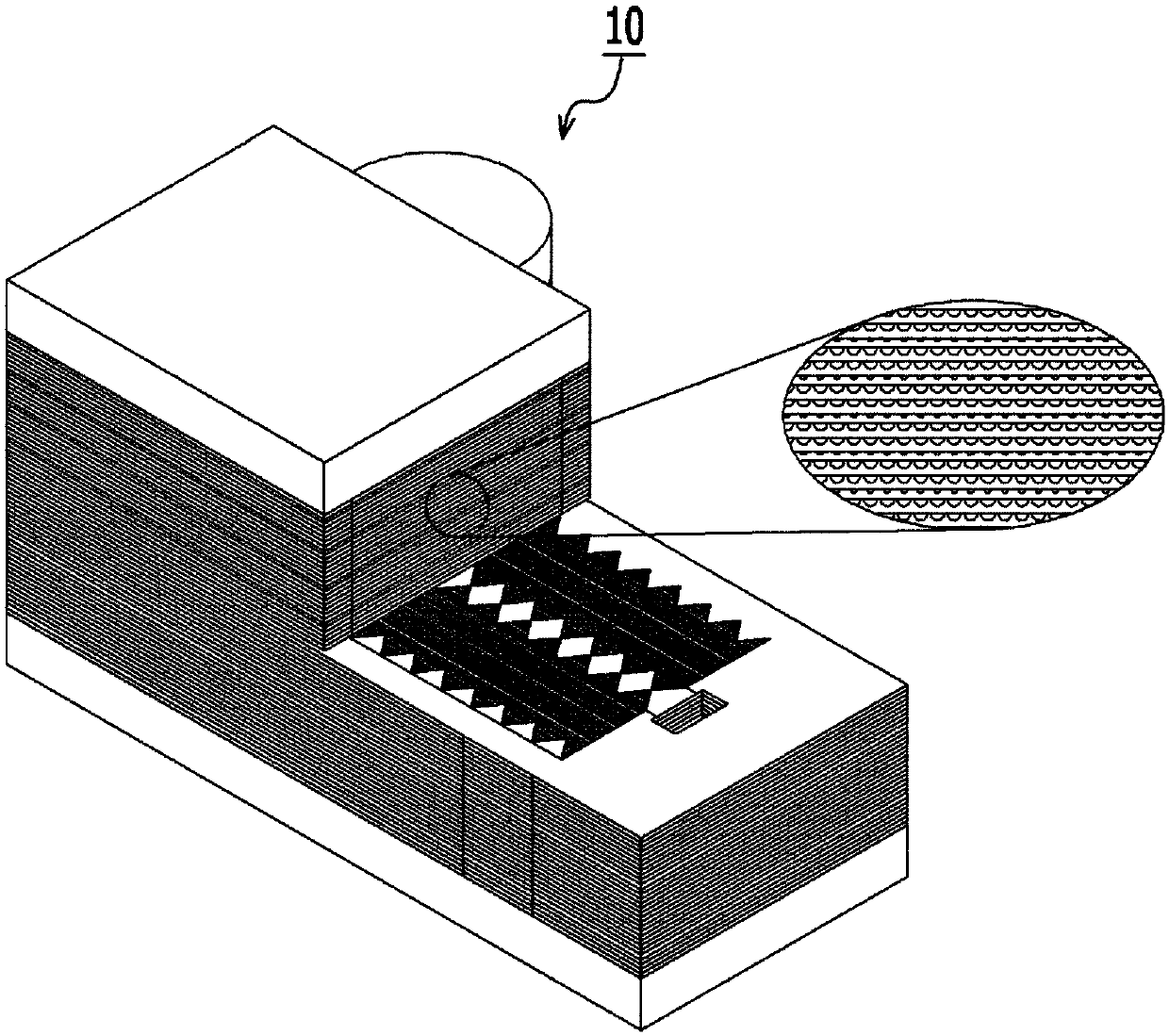

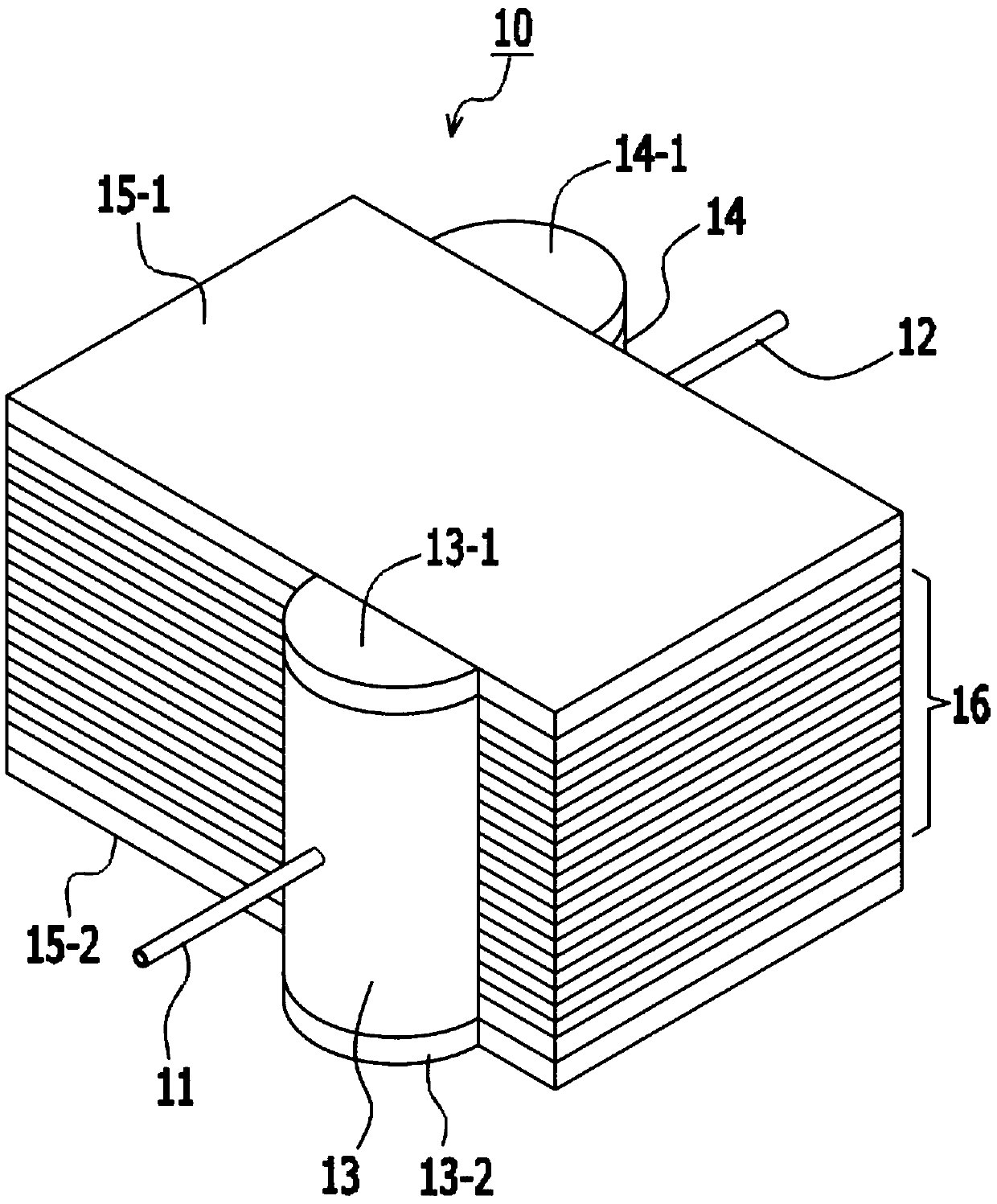

[0075] Figure 6 is a perspe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com