Preparation method of porous nickel-based copper rhenium composite hydrogen evolution electrode

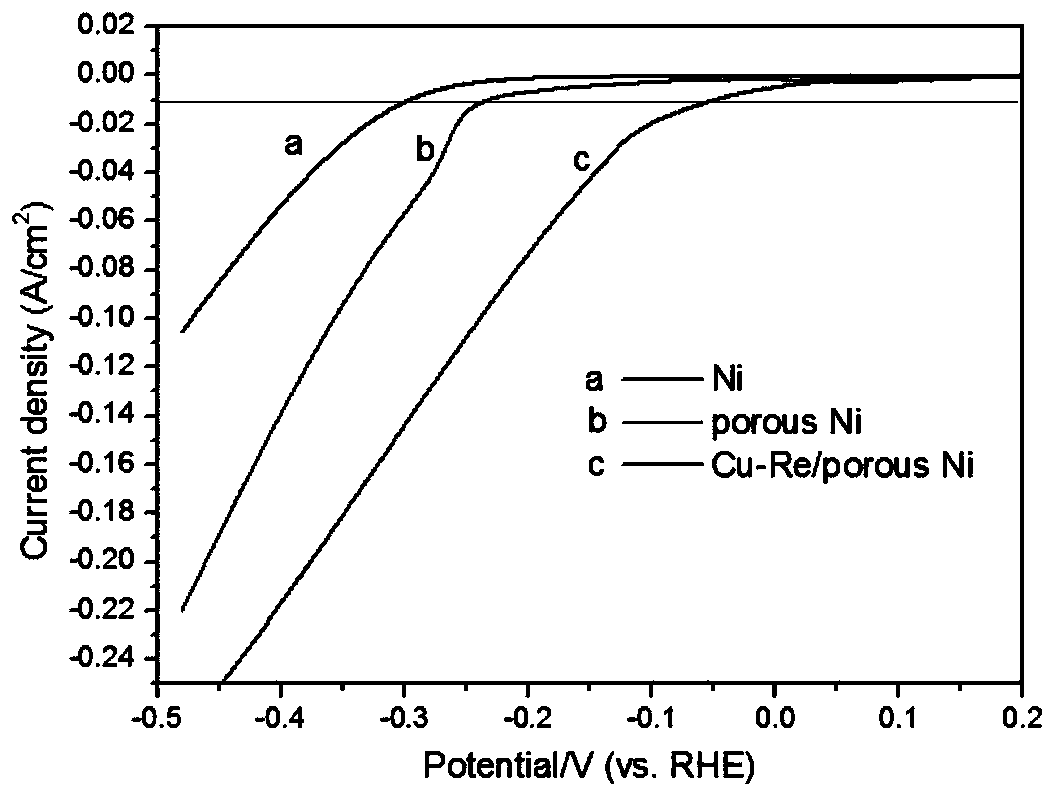

A technology of hydrogen evolution electrode and porous nickel, which is applied in the direction of electrodes, electrolysis process, electrolysis components, etc., can solve the problems of complex loading process of active materials, difficulty in regulating the pore structure of the matrix, and difficult control of loading capacity, etc., and achieve excellent catalytic hydrogen evolution effect, excellent Hydrogen evolution catalytic activity, the effect of enhancing electrocatalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] (1), pretreatment of Ni substrate

[0041] First, grind the Ni substrate with 400#, 800# sandpaper to remove the oxide film on the surface of the Ni substrate, then put it into absolute ethanol for ultrasonic treatment for 5 minutes, and finally rinse it with deionized water and dry the water, seal the Ni substrate, and expose it The area is 1×1cm 2 , to be used after the sealant is air-dried;

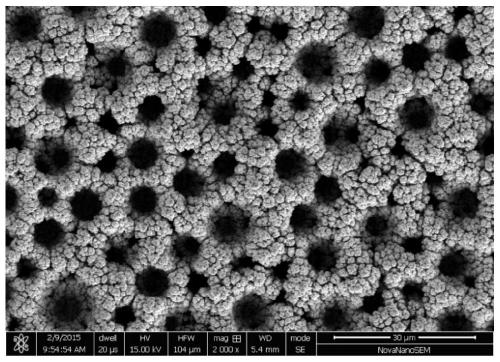

[0042] (2) Preparation of porous nickel-based precursor by electrodeposition

[0043] A two-electrode system is adopted, with the Ni substrate processed in step (1) as the working electrode, the platinum electrode as the counter electrode, and the mixed aqueous solution containing 0.2mol / L nickel chloride and 0.85mol / L ammonium chloride as the electrolyte, The pH of the solution was adjusted to 1 with hydrochloric acid, the electrodeposition temperature was 25°C, and at 5.0A / cm 2 Depositing at a current density of 10 seconds, using the hydrogen bubbles generated by the cathod...

Embodiment 2

[0048] (1), pretreatment of Ni substrate

[0049] First, grind the Ni substrate with 400#, 800# sandpaper to remove the oxide film on the surface of the Ni substrate, then put it into absolute ethanol for ultrasonic treatment for 5 minutes, and finally rinse it with deionized water and dry the water, seal the Ni substrate, and expose it The area is 1×1cm 2 , to be used after the sealant is air-dried;

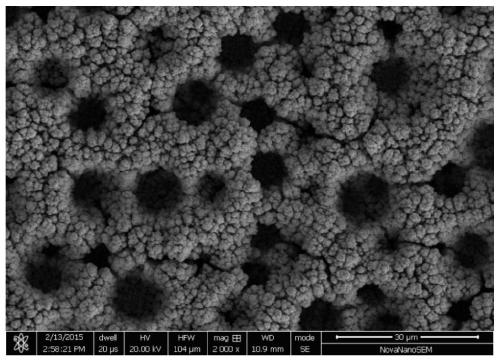

[0050] (2) Preparation of porous nickel-based precursor by electrodeposition

[0051] A two-electrode system is adopted, with the Ni substrate processed in step (1) as the working electrode, the platinum electrode as the counter electrode, and the mixed aqueous solution containing 0.1mol / L nickel chloride and 3mol / L ammonium chloride as the electrolyte, hydrochloric acid Adjust the pH of the solution to 3, and the electrodeposition temperature to 35°C, at 1.5A / cm 2 Depositing at a current density of 25 seconds, using the hydrogen bubbles generated by the cathodic hydrogen evo...

Embodiment 3

[0055] (1), pretreatment of Ni substrate

[0056] First, grind the Ni substrate with 400#, 800# sandpaper to remove the oxide film on the surface of the Ni substrate, then put it into absolute ethanol for ultrasonic treatment for 5 minutes, and finally rinse it with deionized water and dry the water, seal the Ni substrate, and expose it The area is 1×1cm 2 , to be used after the sealant is air-dried;

[0057] (2) Preparation of porous nickel-based precursor by electrodeposition

[0058] A two-electrode system is adopted, with the Ni substrate processed in step (1) as the working electrode, the platinum electrode as the counter electrode, and the mixed aqueous solution containing 0.1mol / L nickel chloride and 0.85mol / L ammonium chloride as the electrolyte, The pH of the solution was adjusted to 5 with hydrochloric acid, the electrodeposition temperature was 45°C, and at 2A / cm 2 Depositing at a current density of 25 seconds, using the hydrogen bubbles generated by the cathodic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com