SCR flue gas denitration catalyst with wide temperature window, preparation method and application of catalyst

A denitration catalyst and catalyst technology, which are applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc. Issues such as the amount of vanadium

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

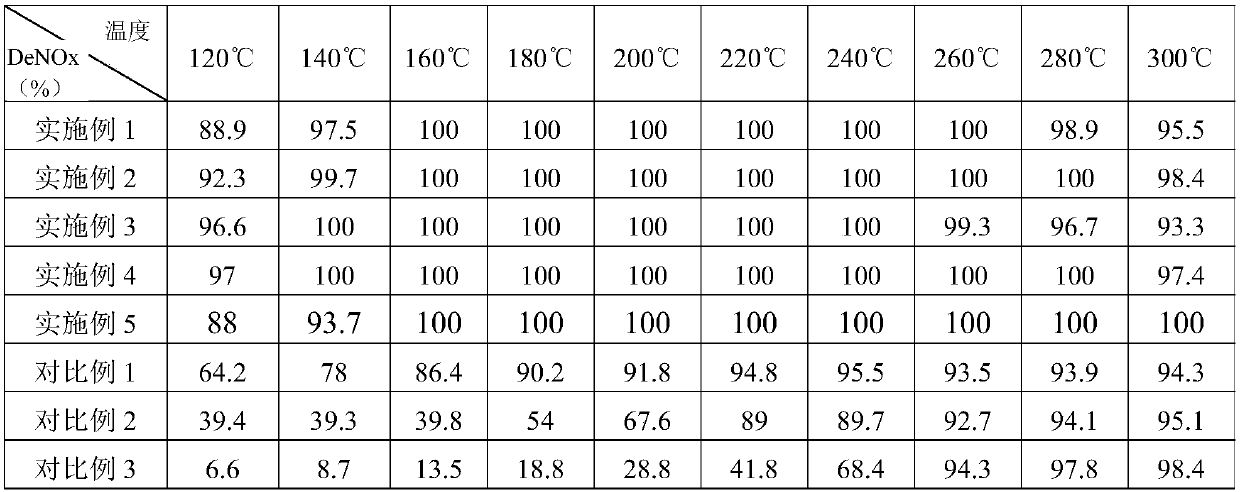

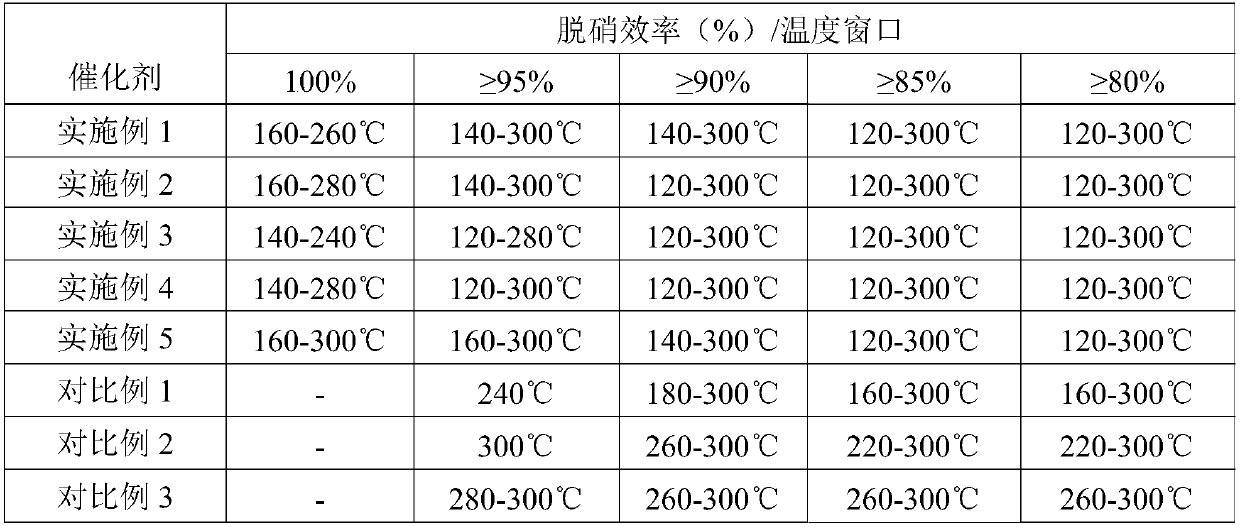

Examples

preparation example Construction

[0032] Another aspect of the present invention provides a method for preparing a wide temperature window SCR flue gas denitrification catalyst, wherein the method comprises the following steps:

[0033] (1) Mix oxalic acid, iron salt, manganese salt and water to obtain solution A;

[0034] (2) mixing and aging oxalic acid, ammonium metavanadate and water to obtain aged vanadium precursor solution B;

[0035] (3) solution A and solution B are mixed, obtain the oxalate double salt precursor solution of metal;

[0036] (4) disperse the carrier nano-titanium dioxide in the oxalate double salt precursor solution of the metal and carry out wet impregnation;

[0037] (5) Calcining the reaction mixture after step (4).

[0038] According to the present invention, based on the total weight of the catalyst, the amount of the carrier is such that the content of the carrier in the catalyst can be 85-95% by weight, preferably 88-92% by weight.

[0039] Wherein, the molar ratio of the amoun...

Embodiment 1

[0062] This example is to illustrate the preparation method of the wide temperature window SCR flue gas denitrification catalyst provided by the present invention.

[0063] (1) Preparation of the impregnating solution: Weigh the solid oxalic acid and fully dissolve it in deionized water, add the solid ferric nitrate nonahydrate to obtain a yellow-green solution. After fully stirring for 30 min, 50% by weight of manganese nitrate aqueous solution was added, and fully stirred to obtain a clear and transparent solution A.

[0064] At the same time, the oxalic acid solid was weighed and fully dissolved in deionized water, and the ammonium metavanadate solid was added to obtain an orange-yellow solution. After fully aging at 60°C for 4 hours, a light blue solution B was obtained.

[0065] Mix A and B solutions evenly and stir well to obtain a clear and transparent impregnating solution.

[0066] Wherein, the molar ratio of the amount of ferric nitrate nonahydrate in terms of Fe e...

Embodiment 2

[0070] This example is to illustrate the preparation method of the wide temperature window SCR flue gas denitrification catalyst provided by the present invention.

[0071] (1) Preparation of the impregnating solution: Weigh the solid oxalic acid and fully dissolve it in deionized water, add the solid ferric nitrate nonahydrate to obtain a yellow-green solution. After fully stirring for 30 min, 50% by weight of manganese nitrate aqueous solution was added, and fully stirred to obtain a clear and transparent solution A.

[0072] At the same time, the oxalic acid solid was weighed and fully dissolved in deionized water, and the ammonium metavanadate solid was added to obtain an orange-yellow solution. After fully aging at 65°C for 4.5 hours, a light blue solution B was obtained.

[0073] Mix A and B solutions evenly and stir well to obtain a clear and transparent impregnating solution.

[0074] Wherein, the molar ratio of the amount of ferric nitrate nonahydrate in terms of Fe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com