Electric bag composite dust removal device

A technology of dust removal device and electric bag compounding, which is applied in the direction of combination device, dispersed particle separation, chemical instrument and method, etc., can solve the problems of increasing the resistance of the dust collector, unable to realize energy saving, manufacturing difficulties, etc., and achieve work reliability and stability. The effect of enhanced performance, significant dust removal effect, and reduced equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

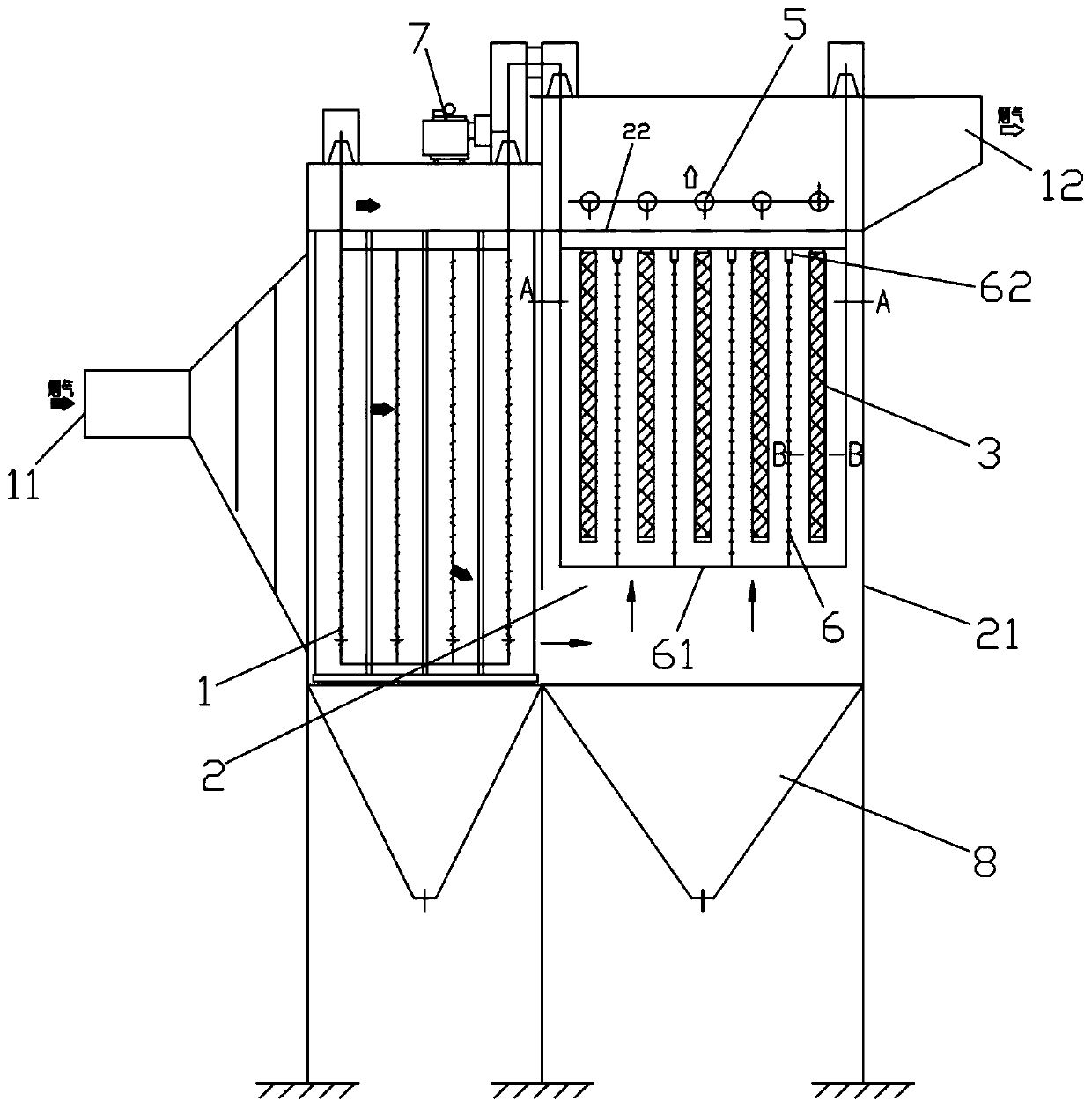

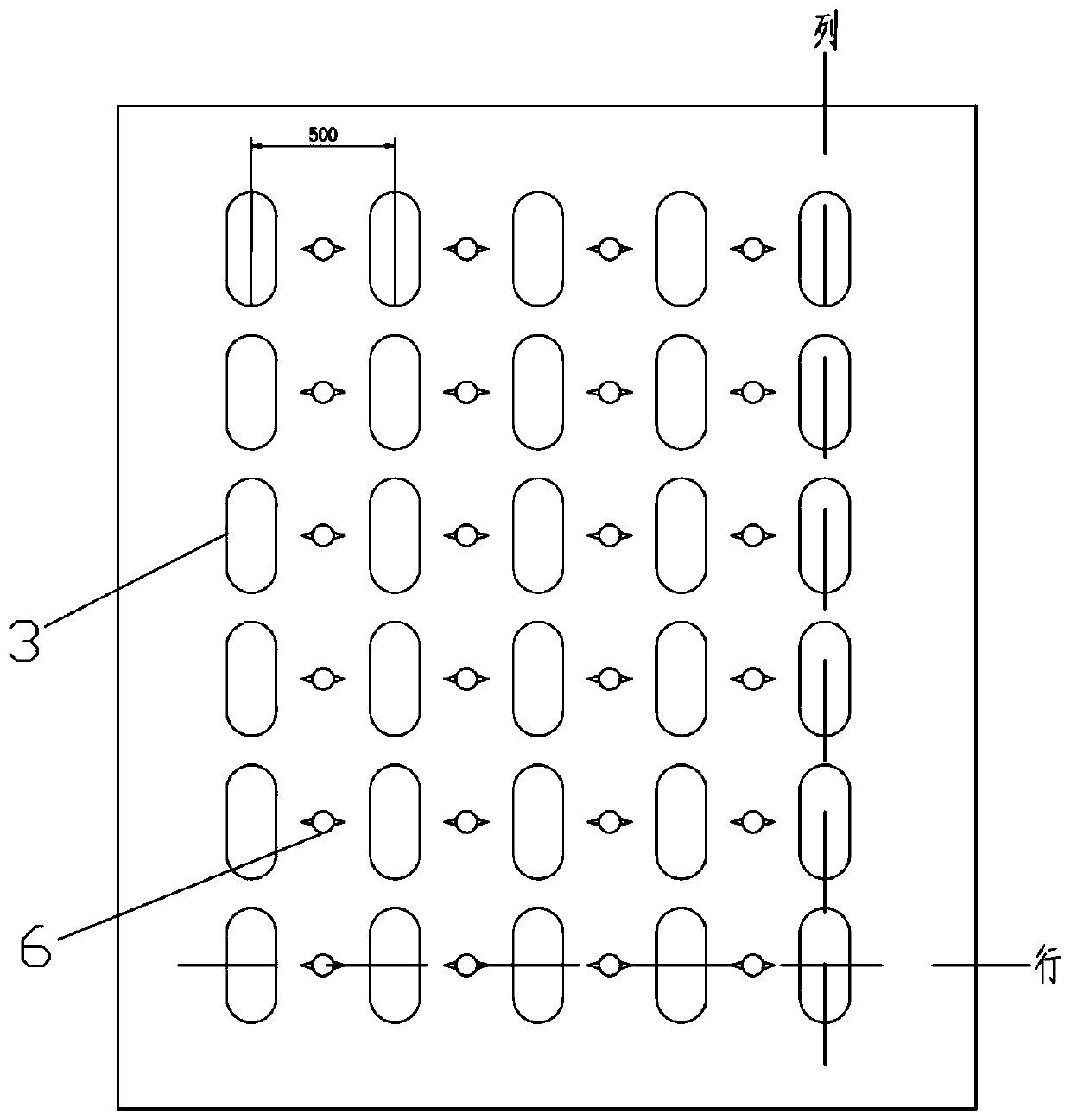

[0033] Embodiment 1 is a preferred embodiment of the present invention. An electric bag composite dedusting device comprises an electric field area 1 at the front and an electric bag mixing area 2 at the rear, and the electric field area 1 and the electric bag mixing area 2 communicate with each other. After the dust-containing flue gas is introduced from the flue gas inlet 11 at the left end of the device, it enters the electric field area 1 at the front end evenly through the action of the multi-layer air distribution plate in the air intake box, and the flue gas removes most of the dust under the action of the electric field area 1 Dust and flue gas that has not been completely purified enter the electric bag mixing area 2 at the rear from the lower part of the electric field area 1. The electric field area 1 of the dust removal device is not the key point of the present invention, and this structure is relatively common in the prior art, and will not be repeated here.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com