Optimization method for spectrum harmonic averaging of rotating machinery

An optimization method and technology of rotating machinery, applied in the testing of mechanical components, testing of machine/structural components, complex mathematical operations, etc., can solve the problems of difficult feature extraction, influence of co-frequency interference, low energy of feature information, etc., to achieve the effect Obviously, improve the signal-to-noise ratio, the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

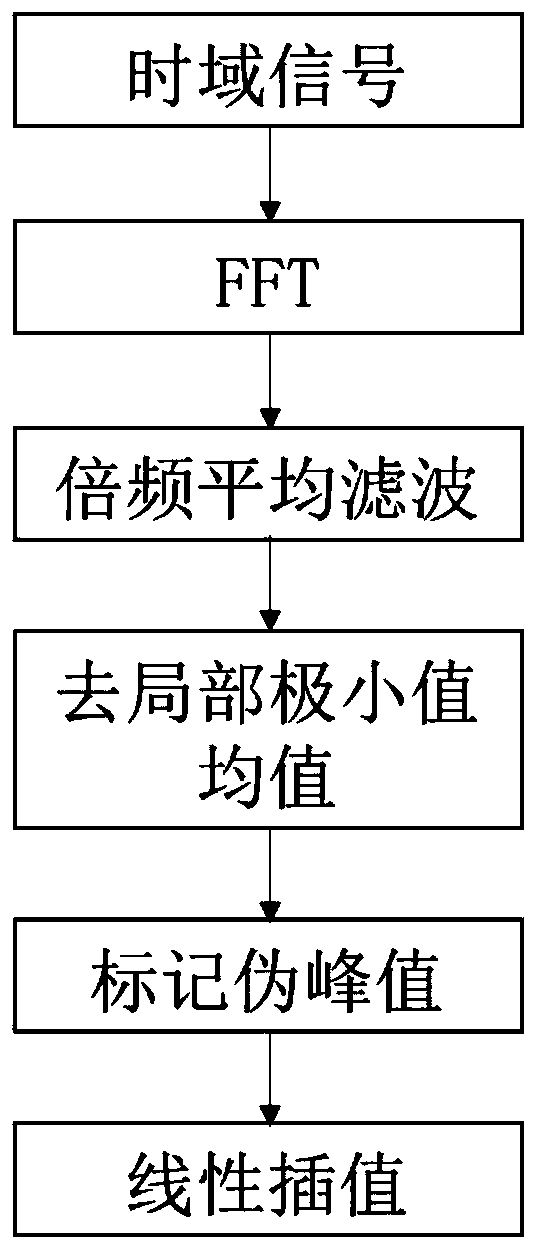

[0029] Embodiment 1, with reference to figure 1 , a method for optimizing the frequency spectrum harmonic averaging of rotating machinery, comprising the following steps:

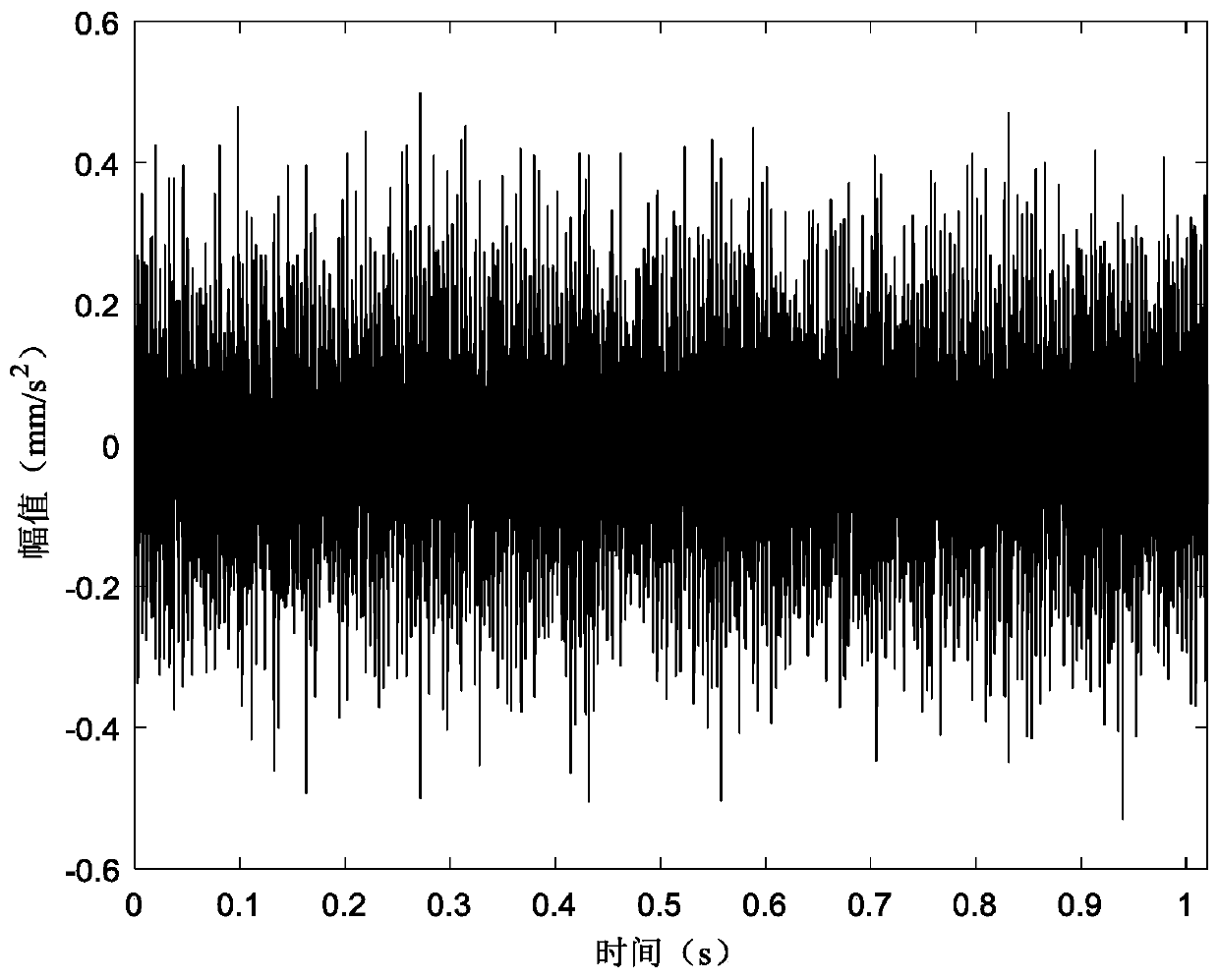

[0030] Step 1) Perform Fourier transform on the original vibration signal to obtain the signal spectrum amplitude sequence {A i}, {i=1,2,L,N}, N is the number of sampling points;

[0031] Step 2 Determine the upper limit F of the signal analysis frequency band according to the equipment operating conditions and component parameter information, and obtain the analysis frequency range 0-F. The analysis frequency range 0-F contains 2-6 harmonics of the characteristic frequency. Mapping to its frequency division area, causing unnecessary false frequencies, and calculating the frequency F t Get 2-5 times of F, and less than half of the sampling frequency, in the present embodiment, F=1000Hz, F t = 2000Hz;

[0032] Step 3) From raw spectrum 0-F t In the frequency band amplitude sequence, all the spectral lin...

Embodiment 2

[0040] Embodiment 2, with reference to figure 1 , a method for optimizing the frequency spectrum harmonic averaging of rotating machinery, comprising the following steps:

[0041] Step 1) Perform Fourier transform on the original vibration signal to obtain the signal spectrum amplitude sequence {A i}, {i=1,2,L,N}, N is the number of sampling points;

[0042] Step 2) Determine the upper limit F of the signal analysis frequency band according to the equipment operating conditions and component parameter information, and obtain the analysis frequency range 0-F. The analysis frequency range 0-F contains 2-6 harmonics of the characteristic frequency. The component is mapped to its frequency division area, causing unnecessary false frequencies, and the frequency F is calculated t Get 2-5 times of F, and less than half of the sampling frequency, in the present embodiment, F=200Hz, F t = 800Hz;

[0043] Step 3) From raw spectrum 0-F t In the frequency band amplitude sequence, all...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com