Method and system for early warning of failures of air compressor applied to chip production, as well as relative device

A fault warning and air compressor technology, applied in mechanical equipment, machines/engines, liquid variable capacity machinery, etc., can solve problems that threaten the life safety of on-site workers, reduce corporate profits, and cylinder explosions, etc., to improve safety and economy, and reduce the effect of failure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

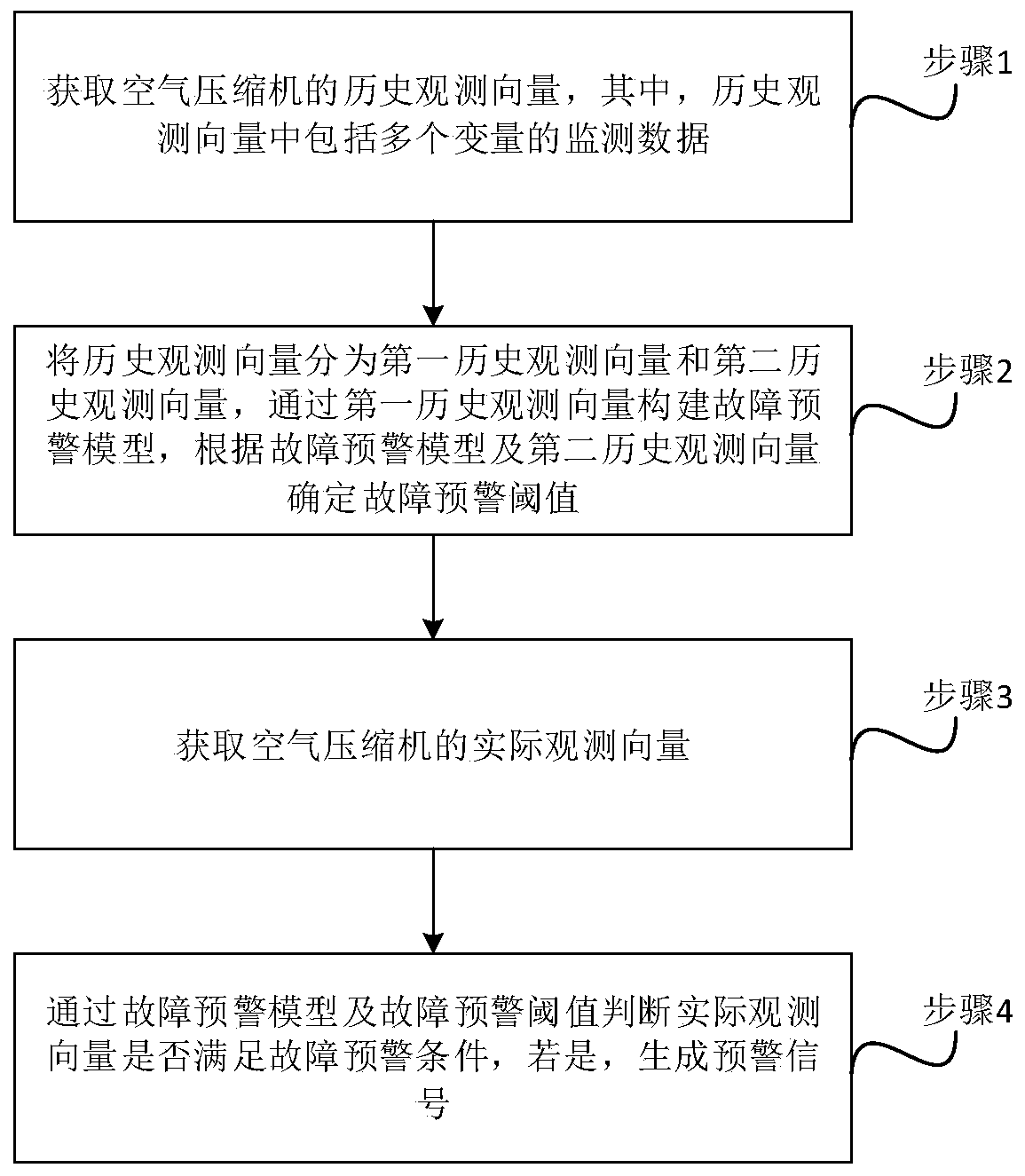

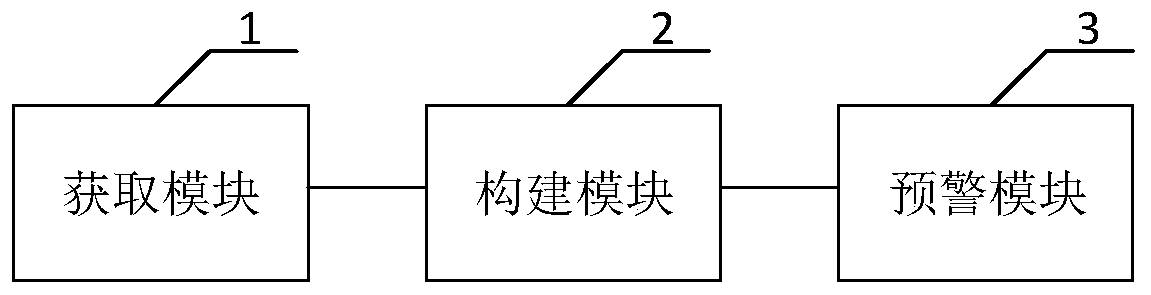

[0048] The core of this application is to provide an air compressor fault early warning method, system and related devices applied to chip production. When it is determined that the actual observation vector meets the early warning conditions, a fault early warning signal is generated, so that the on-site staff can find the air compressor in advance. Early signs of failure, take correct measures to reduce failure losses and greatly improve the safety and economy of starting the production process.

[0049] In order to make the purposes, technical solutions and advantages of the embodiments of the present application clearer, the technical solutions in the embodiments of the present application will be clearly and completely described below in conjunction with the drawings in the embodiments of the present application. Obviously, the described embodiments It is a part of the embodiments of this application, not all of them. Based on the embodiments in this application, all othe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com