Protecting gloves and weaving method thereof

A protective glove and yarn technology, applied in protective clothing, weft knitting, knitting, etc., can solve the problems of wear resistance, cut resistance, tear resistance and puncture resistance, and achieve excellent protection performance and improve Good comfort and good cutting resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A method for weaving protective gloves, comprising the steps of preparing first yarns, second yarns and third yarns respectively, and double-sided knitting the first yarns, second yarns and third yarns Woven into protective gloves, the first yarn and the second yarn are located on one side of the protective glove, and the third yarn is located on the other side of the protective glove; the first yarn is made of polyethylene fiber, glass fiber, stainless steel wire, spandex wire The second yarn is composed of aramid fiber, polyester fiber and nylon fiber, and the third yarn is functional fiber: moisture-absorbing and breathable fiber.

[0029] The covering steps of the first yarn are as follows:

[0030] S1. With 120D glass fiber and 60 μm stainless steel wire as the first core wire, the first core wire is covered with 100D spandex yarn to obtain the first covered yarn semi-finished product. The twist is 480 twists during coating. The direction is Z twist; among them, t...

Embodiment 2

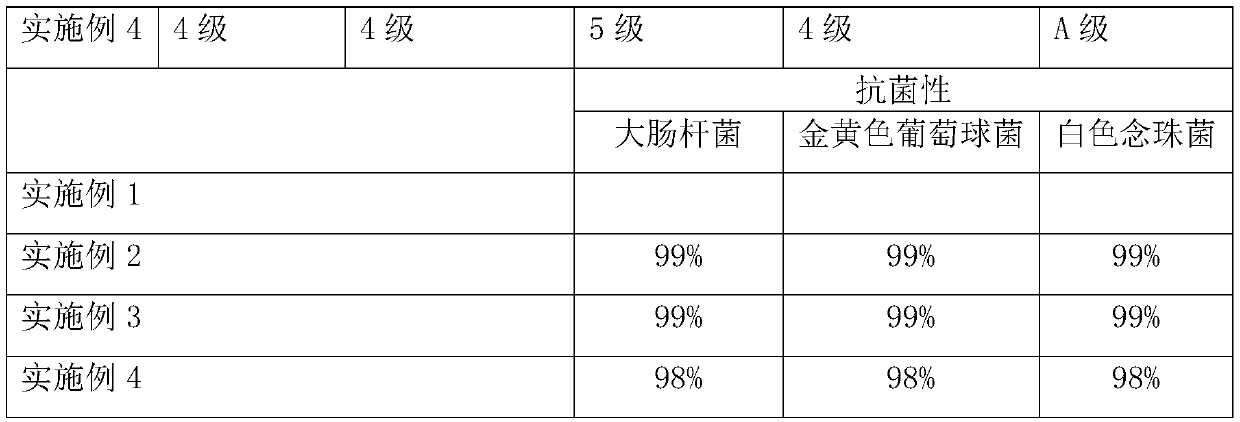

[0036] A method for weaving protective gloves, comprising the steps of preparing first yarns, second yarns and third yarns respectively, and double-sided knitting the first yarns, second yarns and third yarns Woven into protective gloves, the first yarn and the second yarn are located on one side of the protective glove, and the third yarn is located on the other side of the protective glove; the first yarn is made of polyethylene fiber, glass fiber, stainless steel wire, spandex wire and at least three kinds of nylon filaments, the second yarn is composed of aramid fiber, polyester fiber and nylon fiber, and the third yarn is functional fiber: antibacterial fiber.

[0037] The covering steps of the first yarn are as follows:

[0038] S1. With 120D glass fiber and 60 μm stainless steel wire as the first core wire, the first core wire is covered with 120D spandex yarn to obtain the first covered yarn semi-finished product. The twist is 480 twists during coating. The direction ...

Embodiment 3

[0047] A method for weaving protective gloves, comprising the steps of preparing first yarns, second yarns and third yarns respectively, and double-sided knitting the first yarns, second yarns and third yarns Woven into protective gloves, the first yarn and the second yarn are located on one side of the protective glove, and the third yarn is located on the other side of the protective glove; the first yarn is made of polyethylene fiber, glass fiber, stainless steel wire, spandex wire The second yarn is composed of aramid fiber, polyester fiber and nylon fiber, and the third yarn is functional fiber: antibacterial fiber and moisture-absorbing and breathable fiber.

[0048] The covering steps of the first yarn are as follows:

[0049] S1. With 120D glass fiber and 60 μm stainless steel wire as the first core wire, the first core wire is covered with 120D spandex yarn to obtain the first covered yarn semi-finished product. The twist is 480 twists during coating. The direction i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com