Preparation method for carbon nitride nanofibers and application thereof

A technology of nanofibers and carbon nitride, applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve the problem of low catalytic efficiency of carbon nitride, improve catalytic performance, and increase specific surface area , Increase the effect of catalytic active sites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Weigh 1g of melamine, add 48mL of water, heat to 80°C to dissolve to obtain an aqueous solution of melamine; add 0.33g of phytic acid and 16.5mL of water to another container, heat to 80°C to dissolve to obtain an aqueous solution of phytic acid. Mix the melamine aqueous solution and the phytic acid aqueous solution, heat to 85°C and stir for 2 hours, transfer the resulting mixed solution to an ice-water bath to cool, and leave it for 0.5 hours to obtain a melamine / phytic acid hydrogel, and use a freeze dryer to dry the hydrogel Gel to obtain melamine / phytic acid xerogel. The obtained melamine / phytic acid xerogel was calcined in a muffle furnace at 550° C. for 4 hours to prepare carbon nitride nanofibers.

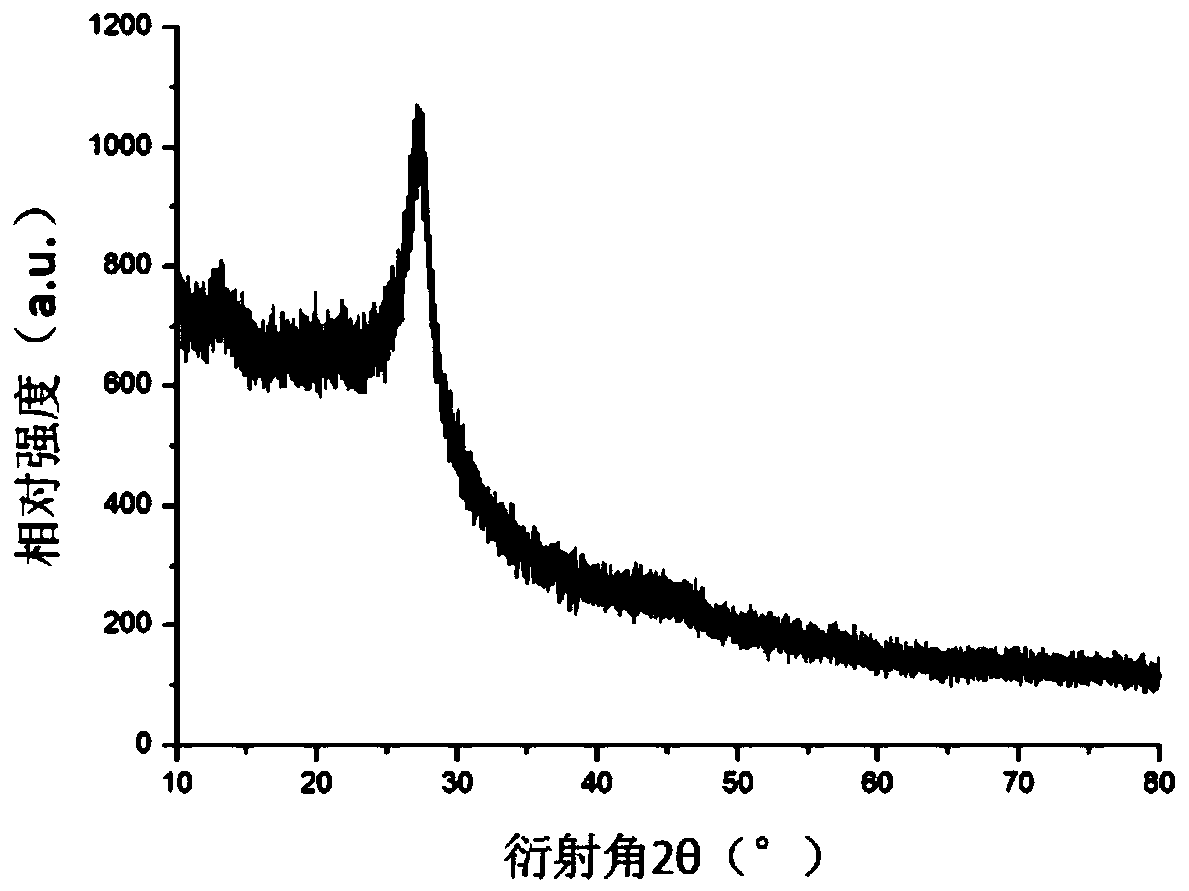

[0031] The scanning electron microscope of the melamine / phytic acid xerogel prepared in this embodiment is as follows: figure 1 As shown, it can be seen that the melamine / phytic acid in the xerogel is in the shape of nanofibers with uniform size; the scanning electr...

Embodiment 2

[0033] Weigh 2g of melamine, add 48mL of water, heat to 80°C to dissolve to obtain an aqueous solution of melamine; add 0.5g of phytic acid and 14.5mL of water to another container, heat to 60°C to dissolve to obtain an aqueous solution of phytic acid. Mix the melamine aqueous solution and the phytic acid aqueous solution, heat to 60°C and stir for 2 hours, transfer the resulting solution to an ice-water bath to cool, and leave it for 0.5 hours to obtain a melamine / phytic acid hydrogel, and use a freeze dryer to dry the melamine / phytic acid gel. acid hydrogel to obtain melamine / phytic acid xerogel. The obtained melamine / phytic acid xerogel was calcined in a muffle furnace at 450° C. for 6 hours to prepare carbon nitride nanofibers.

Embodiment 3

[0035] Weigh 1.5g melamine, add 48.8mL water, heat to 85°C to dissolve to obtain melamine aqueous solution; add 2g phytic acid and 48mL water to another container, heat to 80°C to dissolve to obtain phytic acid aqueous solution. Mix the melamine aqueous solution and the phytic acid aqueous solution, heat to 85°C and stir for 2 hours, transfer the resulting mixed solution to an ice-water bath for cooling, and leave it to stand for 1 hour to obtain a melamine / phytic acid hydrogel, and use a freeze dryer to dry the melamine / phytic acid gel. Phytic acid hydrogel to obtain melamine / phytic acid xerogel. The obtained melamine / phytic acid xerogel was calcined in a muffle furnace at 600° C. for 4 hours to prepare carbon nitride nanofibers.

[0036] Photocatalytic decomposition of water to produce hydrogen:

[0037]The carbon nitride nanofibers prepared in Example 1 were irradiated with visible light to photolyze water to produce hydrogen; Phase carbon nitride refers to the carbon nit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com