A kind of magnesium alloy with self-generated gradient structure and its preparation method and application

A gradient structure, magnesium alloy technology, applied in the direction of prosthesis, medical science, etc., can solve the problems of easy peeling and coating, uneven coating, etc., to extend the mechanical integrity time, improve corrosion resistance, and achieve good medical effects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

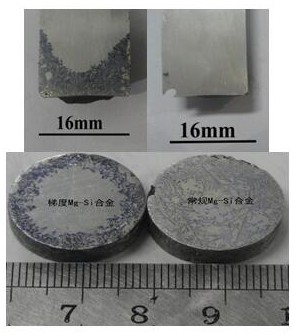

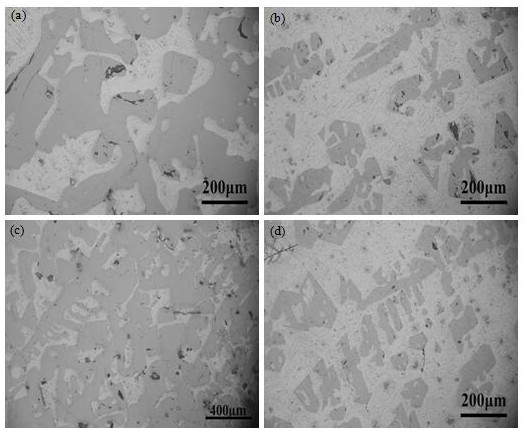

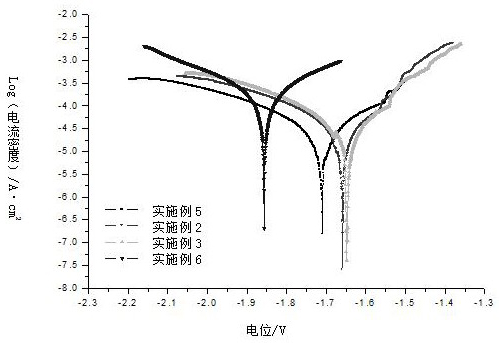

[0038] Example 1: Preparation of a Mg-Si-based magnesium alloy with an autogenous gradient structure with a Si content of 5% by weight.

[0039] Take high-purity magnesium (purity greater than 99.99%) and high-purity silicon (purity greater than 99.99%), mix according to the mass ratio of Mg and Si at a ratio of 95:5, and control the content of impurity elements to less than 0.1%. Put the two raw materials into the smelting furnace for smelting. During the smelting process, argon is used as a protective gas, and the temperature is raised to 820°C to make the ingredients uniform and the raw materials are fully melted. During the heating process, electromagnetic induction stirring is applied. After the raw materials are completely melted, the temperature is lowered to 720°C and kept for 15 minutes. The speed is directed to pull away from the heating coil, so that the surface layer of the bottom and the surface layer of the side of the magnesium alloy form a corrosion-resistant l...

Embodiment 2

[0040] Example 2: A Mg-Si-based magnesium alloy with an autogenous gradient structure with a Si element content of 7% by weight was prepared.

[0041] Take high-purity magnesium (purity greater than 99.99%) and high-purity silicon (purity greater than 99.99%), mix according to the mass ratio of Mg and Si of 93:7, and control the content of impurity elements to less than 0.1%. Put the two raw materials into the smelting furnace for smelting. During the smelting process, argon is used as a protective gas, and the temperature is raised to 860°C to make the ingredients uniform and the raw materials are fully melted. During the heating process, electromagnetic induction stirring is applied. After the raw materials are completely melted, the temperature is lowered to 750°C and kept for 20 minutes. The speed is directed to pull away from the heating coil, so that the surface layer of the bottom and the surface layer of the side of the magnesium alloy form a corrosion-resistant layer ...

Embodiment 3

[0042] Example 3: A Mg-Si-based magnesium alloy with an autogenous gradient structure with a Si element weight percentage of 9.9% was prepared.

[0043] Take high-purity magnesium (purity greater than 99.99%) and high-purity silicon (purity greater than 99.99%), mix according to the mass ratio of Mg and Si at a ratio of 90.1:9.9, and control the content of impurity elements to less than 0.1%. Put the two raw materials into the smelting furnace for smelting. During the smelting process, argon is used as a protective gas, and the temperature is raised to 900°C to make the ingredients uniform and the raw materials are fully melted. During the heating process, electromagnetic induction stirring is applied. After the raw materials are completely melted, the temperature is lowered to 780°C and kept for 25 minutes. Pull away from the heating coil at a directional speed, so that the surface layer of the bottom and the surface layer of the side of the magnesium alloy form a corrosion-r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com