Polyimide precursor, precursor composition, polyimide, high temperature resistant transparent polyimide film and preparation method thereof

A technology of transparent polyimide and high temperature resistance, applied in the field of polymer material synthesis, can solve the problems of reduced mechanical properties and reduced heat resistance of high transparent polyimide, and achieves improved regularity, good light transmittance, The effect of improving the degree of plane orientation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] A high-temperature-resistant transparent polyimide film, which is produced by thermal imidization method, and is obtained by casting a polyamic acid precursor composition and temperature-programmed treatment;

[0057] Wherein, the polyamic acid precursor accounts for the mass content of composition and is 10wt%;

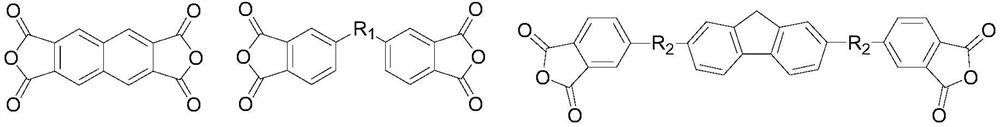

[0058] The diamine monomer used is 2,2-bis[4-(4-aminophenoxy)phenyl]-1,1,1,3,3,3-hexafluoropropane, and the main dianhydride monomer is 4 , 4-(hexafluoroisopropylene) diphthalic anhydride, the dianhydride monomer is 4,4'-oxydiphthalic anhydride;

[0059] The main dianhydride monomer accounts for 70% of the total molar amount of dianhydride, and the controlled dianhydride monomer accounts for 30% of the total molar amount of dianhydride;

[0060] The temperature programming sequence is: room temperature—100°C (10min)—180°C (10min)—260°C (10min)—320°C (10min).

Embodiment 2

[0062] A high-temperature-resistant transparent polyimide film, which is produced by chemical imidization method, is obtained by mixing polyamic acid precursor composition and accelerator, casting and temperature-programmed treatment;

[0063] Wherein, the polyamic acid precursor accounts for the mass content of composition and is 10wt%;

[0064] The diamine monomer used is 2,2-bis[4-(4-aminophenoxy)phenyl]-1,1,1,3,3,3-hexafluoropropane, and the main dianhydride monomer is 4 , 4-(hexafluoroisopropylene) diphthalic anhydride, the dianhydride monomer is 4,4'-oxydiphthalic anhydride;

[0065] The main dianhydride monomer accounts for 70% of the total molar amount of dianhydride, and the controlled dianhydride monomer accounts for 30% of the total molar amount of dianhydride;

[0066] The accelerator is composed of pyridine and acetic anhydride in a mass ratio of 1:1, the mass ratio of the sum of the catalyst and dehydrating agent to the solvent is 3:7; the mass ratio of the prec...

Embodiment 3

[0069] A high-temperature-resistant transparent polyimide film, which is produced by chemical imidization method, is obtained by mixing polyamic acid precursor composition and accelerator, casting and temperature-programmed treatment;

[0070] Wherein, the polyamic acid precursor accounts for the mass content of composition and is 10wt%;

[0071] The diamine monomer used is 2,2-bis[4-(4-aminophenoxy)phenyl]-1,1,1,3,3,3-hexafluoropropane, and the main dianhydride monomer is 4 , 4-(hexafluoroisopropylene) diphthalic anhydride, the dianhydride monomer is 4,4'-oxydiphthalic anhydride;

[0072] The main dianhydride monomer accounts for 70% of the total molar amount of dianhydride, and the controlled dianhydride monomer accounts for 30% of the total molar amount of dianhydride;

[0073] The accelerator is composed of pyridine and acetic anhydride in a mass ratio of 1:1; the mass ratio of the sum of the catalyst and dehydrating agent to the solvent is 3:6; the mass ratio of the prec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com